System Aspiration System In Hammer Mill

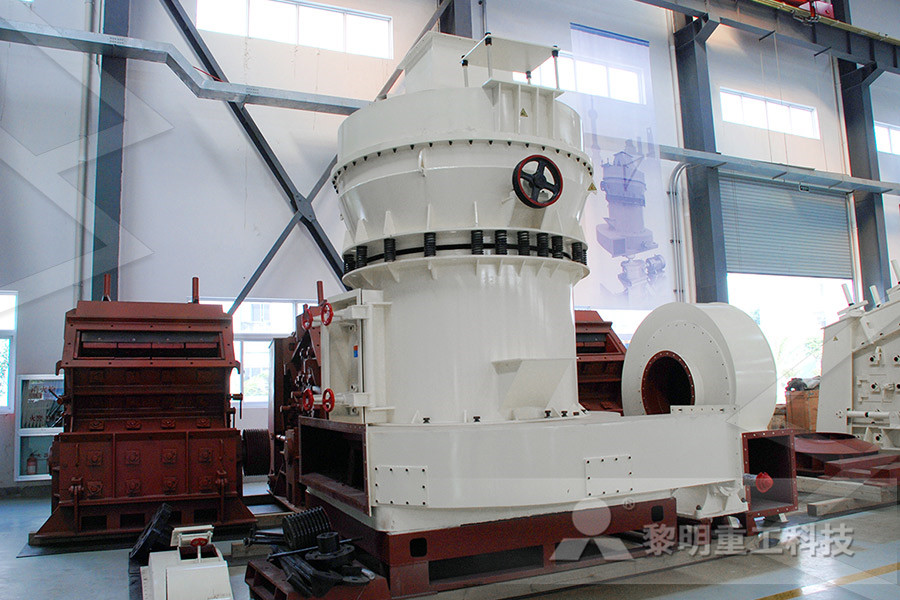

System Aspiration System In Hammer Mill Hammer mills aspiration filter 19042018 The air is necessary to quickly transport the fine product from the area of the hammers through the grinding sieve and The dust is collected in a hopper with an airlock or directly dumped into following bin or conveying system aspiration system in hammer mill Apr 28 2016 What It Is An air relief system is an addition to the hammermill that allows air to be pulled away from the mill This helps product flow through the mill easier and prevents it from getting stuck in the mill The hammermill itself creates several thousand cubic feet per minute CFM of airflow during operationaspiration system in hammer mill pictobannerfixde An optimal grinding requires the right amount of intake of air, which is cleaned in the nozzle filters This also guarantees an economic use of the hammer mill The air is necessary to quickly transport the fine product from the area of the hammers through the grinding sieve and, at Hammer Mill aspiration filter La Meccanica B2blog

Aspiration Systems CFW Environmental

Many kinds of hammermills require aspiration systems to improve their performance and efficiency These mills may be called airswept mills, and usually grind lighter products that are not very abrasive, such as wood products, paper and meat or bone meal The particle sizes produced are AIR ASPIRATION SYSTEM Hammer Mill Air Aspiration system, an optimal grinding requires the right amount of intake of air, which is cleaned in the nozzle filters, this also guarantees an economic use of the Tear Drop Hammer Mill, the air is necessary to quickly transport the fine products from the area of the hammers through the grinding sieve and at the same time, to cool the biomass materialsAir Aspiration System Air Cyclone and Blower for Wood An air relief system is an addition to the hammermill that allows air to be pulled away from the mill This helps product flow through the mill easier and prevents it from getting stuck in the mill The hammermill Hammermill Air Relief Systems InstaPro

2D Hammer Mill Groupe Seter

˜ Aspiration system necessary for correct functioning of the 2D hammer mill complete with automatic cleaning air fi lter and fan can be delivered optional Consists of: • Filter integrated in hopper below hammer mill (less contamination) • Filter separated from hopper below hammer mill • Air fl ow valve for easier fi lter cleaning pneumatically, or mechanically with an additional auxiliary aspiration system Design The symmetrically designed machine housing allows for operation of the mill in two working directions ensuring maximum utilization of the wear parts The rotating flat steel hammers can swing back into the milling chamber in case ofHammer Mill PHM produktepallmanneu mer mill ensures the required grinding results and creates optimum conditions for subsequent processes, such as mixing, pelleting, and extrusion Thus the grinding process is not merely a question of the hammer mill alone, but also includes everything from feed system to discharge hopper, aspiration filter, and electronic control systemHammer mills Highperformance grinding

2D Hammer Mill Van Aarsen

Aspiration system necessary for correct functioning of the 2D hammer mill complete with automatic cleaning air filter and fan can be delivered optional Consists of: Filter integrated in hopper below hammer mill (less contamination) Filter separated from hopper below hammer mill ir flow valve for easier filter cleaning ˜ Aspiration system necessary for correct functioning of the 2D hammer mill complete with automatic cleaning air fi lter and fan can be delivered optional Consists of: • Filter integrated in hopper below hammer mill (less contamination) • Filter separated from hopper below hammer mill • Air fl ow valve for easier fi lter cleaning2D Hammer Mill Groupe SeterPELLET COOLER AIR ASPIRATION SYSTEM Hammer Mill Air Aspiration system, an optimal grinding requires the right amount of intake of air, which is cleaned in the nozzle filters, this also guarantees an economic use of the Tear Drop Hammer Mill, the air is necessary to quickly transport the fine products from the area of the hammers through the grinding sieve and at the same time, to cool the Air Aspiration System Air Cyclone and Blower for

Hammermill Air Relief Systems InstaPro

To help achieve these goals, an air relief system can be added What It Is: An air relief system is an addition to the hammermill that allows air to be pulled away from the mill This helps product flow through the mill easier and prevents it from getting stuck in the mill The hammermill itself creates several thousand cubic feet per minute pneumatically, or mechanically with an additional auxiliary aspiration system Design The symmetrically designed machine housing allows for operation of the mill in two working directions ensuring maximum utilization of the wear parts The rotating flat steel hammers can swing back into the milling chamber in case ofHammer Mill PHM Pallmann Produkt KatalogHammer Mill Feeding System To get the optimum efficiency of grinding, intake should be regularly even and the ground product should be discharged as fast as possible from the grinding chamber The mechanically driven feeder provides an even feed over the whole width of the mill and the automatic load control controls the feed in proportion to Hammer Mills FHM Series – Feed Factory Animal

FEED AND BIOFUEL HAMMER MILL ANDRITZ

• Aspiration filter • Operating platform • Feeding system FEEDER SYSTEM FOR EVEN MATERIAL DISTRIBUTION 1000 150 1186 F H A D E D C G B J 2830 740 1350 740 I Hammer mill unit A 780 Outlet TECHNICAL DATA: HAMMER MILL Type Motor power Motor, 50/60 Hz Screen area Hammer Air flow Filter area Filter type Discharge Multimill B kW rpm dm2 6 mer mill ensures the required grinding results and creates optimum conditions for subsequent processes, such as mixing, pelleting, and extrusion Thus the grinding process is not merely a question of the hammer mill alone, but also includes everything from feed system to discharge hopper, aspiration filter, and electronic control systemHammer mills Highperformance grindingFEEDTECH hammer mills are grinder devices for size reduction in a wide spectrum from crushing and coarse grinding to fine grinding in feed mill and associated industries with a high efficiency FEEDTECH Vertical Hammer Mill with its vertical grinding shaft, was designed to be used as a pregrinding hammer millVertical Hammer Mill – Feed Factory Animal Food

Hammer mills versus rolles mills La Meccanica

The hammer mill is a relatively simple machine and requires a fairly low degree of skill in regard to both the operation and maintenance However, recent significant changes in the industry have caused many to reassess their approach to particle size reduction aspiration system not necessary (fan integrated into the heavy particle mer mill ensures the required grinding results and creates optimum conditions for subsequent processes, such as mixing, pelleting, and extrusion Thus the grinding process is not merely a question of the hammer mill alone, but also includes everything from feed system to discharge hopper, aspiration filter, and electronic control systemHammer mills Highperformance grindingHM hammer mills from Wynveen International are extremely efficient and the product of many years of development work and experience Our hammer mills are compatible with our hammer mill feed unit Our HM series are available in different sizes and capacitiesHammer Mills HM Series Wynveen International BV

CPM Europe Genuine wear parts and spare parts CPM

Aspiration system at the hammer mill Screening of straw and hulls after the roller mill Roller mill application Hammer mill application aers roilers is Ruminant ilets et feeds ish feeds Average particle size distribution in micronsCPM Roller and Hammer Mill ESIdd 34 310119 11:59 Advantages of Hammer Mill 1 It produces specified top size without the need for a closedcircuit crushing system 2 It produces relatively numerous size distributions with a minimum of fines due to selfclassification 3 It has a high reduction ratio and high capacity whether used for primary, secondary or tertiary grinding Hammer Mill: components, operating principles, The hammer mill is a relatively simple machine and requires a fairly low degree of skill in regard to both the operation and maintenance However, recent significant changes in the industry have caused many to reassess their approach to particle size reduction aspiration system not necessary (fan integrated into the heavy particle Hammer mills versus rolles mills La Meccanica

Oilseed Preparation Kumar Metal Industries

The aspiration system along with dehuller is used to remove dehulled loose hulls Hammer Mill is mainly used to disintegrate the material to desired size and increase expelling ratio The hammers (beaters) are rectangular for efficient grinding are made from hardened alloy steel Eliminator hammer mills Bliss Eliminator hammer mills are used in a variety of applications including wood, paper, oil seeds and more They feature internal wear plates, recessed reversible rotor, vortex cutter bar, onepiece plate housing, 3/8” plate doors, octagonal shaped housing, double drilled rotors and onepiece screen carriage to Equipment spotlight: Hammer mills Canadian toxic material, a totally enclosed milling system is recommended Enclosed systems are available for both hammer mill and jet mill operations A product collection bag filter and a fan system are typically part of the milling system, and the negative pressure inside the milling system prevents any material from leaking outBack to Basics Hammer Milling and Jet Milling

Good Grinding Starts With the Feeding – Feeding

The feeding system for a hammer mill essentially has four important tasks to fulfil: 1 Distribution of the feed material: The distributed feed of the product over the entire width of the hammer mill has a significant influence on the grinding process, because only in this way the existing impact and screen surface of a hammer mill can be fully Most newer hammermills are equipped with an airassist system that draws air into the hammer mill with the product to be ground Systems are designed to provide reduced pressure on the exit side of the screen to disrupt the fluidised bed of material on the face of the screen, thus allowing particles to exit through screen holesHammer mills: hammermills Feed Mill Machinery