flotation machine belt drive with pulley

flotation machine belt drive with pulley MTD PARTS Arkansas Outdoor Power Equipment xxx washer oil pan a bushing w/ fitting use b belt use or ss a Inquiry Online Job Interview Online Practice Test Question hr The shaft is driven by pulley as shown The machine will require a 1/4hp variable speed motor fitted with a crown pulley to take a 2in belt Motor pulley and speed should be such that with a 6in pulley on the machine, a speed range of from 200 to Laboratory Flotation Equipment TestingPower transmission capacity of belt drive depends on the the coofficiant of friction between the belt and pulley, belt velocity, angle of wrap and the unit mass of the belt If the distance between two pulleys is more, then one side of the belt will be under tension, and it is called the tight sideBelt Drive: Types, Material, Application, Advantages

2 pulleys and belt drives SlideShare

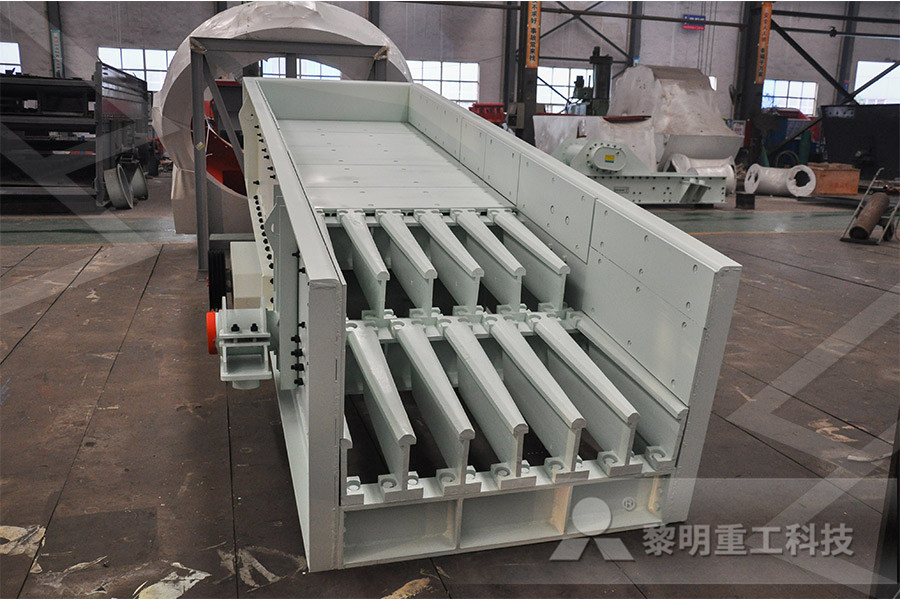

IDLER PULLEY 1) Adjust tension and slack in the belt 2) Increase the belt contact area with pulley 3) To make drive compact 13 APPLICATIONS DRILLING MACHINE WITH SPEED CONE PULLEYS A OPEN BELT DRIVE IN A JIGSAW MACHINE SKIVING MACHINE LATHE MACHINE WITH SPEED CONES AND TIMING BELT This one pulley is mounted nearer to the smaller pulley and we can say also this is placed on the slack side of the belt Let’s understand jockey pulley in detail : It (jockey or idle pulley) helps to increase the angle of contact of the belt, so that belt tension is increased and also the drive provides a highvelocity ratioBelt Drive: Types, Material, Applications, Advantages A machine commissioned to be utilized at a construction site will consist of a VBelt pulley system of 290mm and 1500mm sheave diameters at about 19m apart, driven by a 40 kW engine at 400 rpm The machine will operate under normal torque of lightest medium shock condition with 11 design factor The engineer has to selectBelts (Flexible Mechanical Elements)

BELT DRIVE PREVENTIVE MAINTENANCE AND SAFETY

correct drive Never have contact with a belt drive unless the system is tagged and locked out 2 Test to make sure correct circuit has been turned off 3 Place all machine components in a safe (neutral) position Make sure that moving components are locked down or are in a safe position Make sure that fans cannot unexpectedly freewheel 4 The drilling pulley (1) receives its rotation from drive unit (7) The material to be conveyed is loaded on the belt by one or more feedhoppers (8), mounted over the conveyor belt line, normally places at the tailend sideESSENTIAL COMPONENTS OF BELT CONVEYORS Textile Machine Textile Knitting Machinery 13 15 17 Sawing Machine Sawing Machine – Home Use – 12 14 Sawing Machine – Industrial – 16 18 Belt Conveyor Packaging Machine Belt Conveyor – Light Objects 11 13 15 Packaging Machine 12 14 16 Film Wire Making Machine Calender Extruder 14 16 18 Wire Making Machinery Selection is easy with Timing Pulleys and Belts automatic

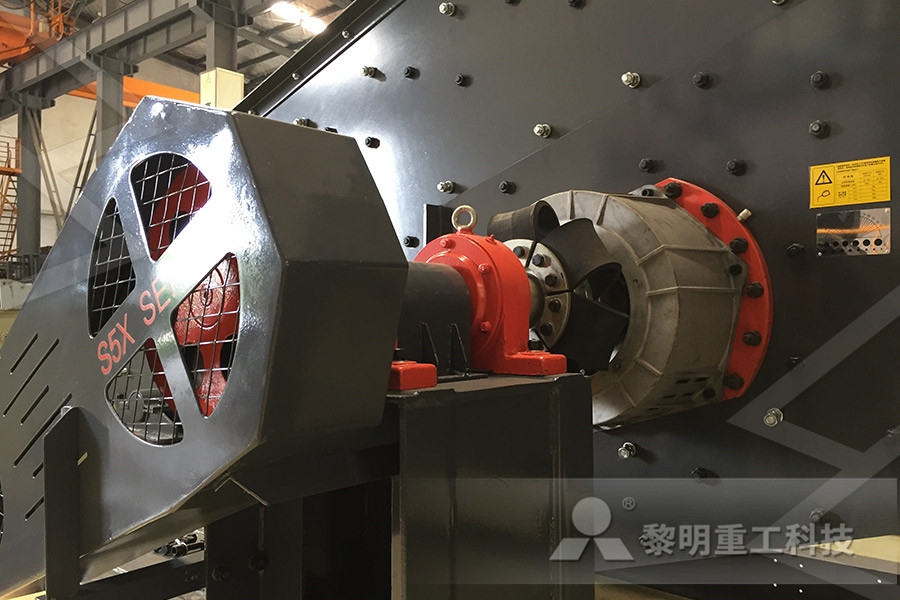

Flotation Machines DR Automation PDF Catalogs

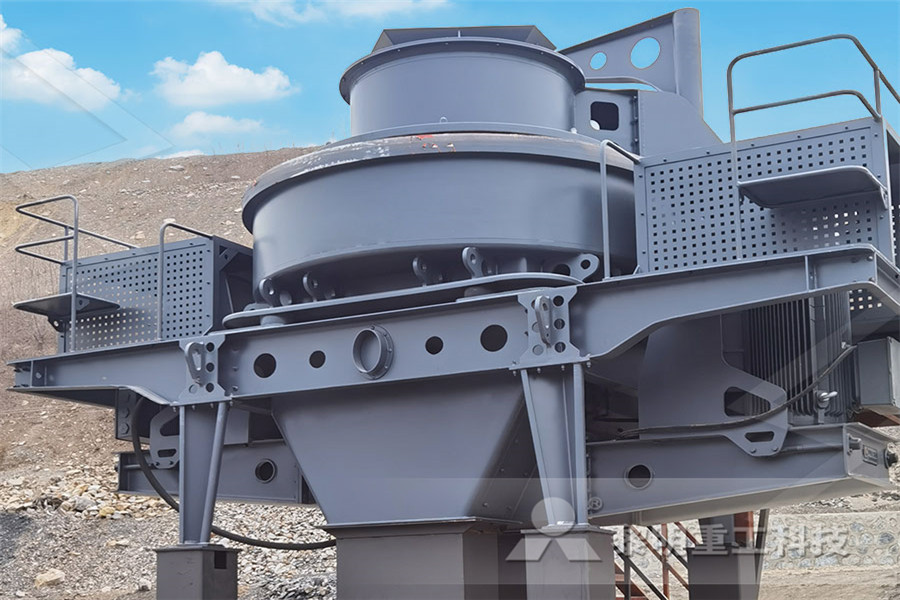

DR flotation machines The mining industry has grown Principle of operation and developed over the years The DR flotation machine is the first and has adapted itself to chang mechanical open type machine to incorpoing economic conditions Single cell drive 4) Dual cell drive 5) Length per cell Trellex pulley and roller lagging Flotation operation process In the flotation cell or copper ore flotation machine the ore pulp after mixing with the drugs is inflated with air through the stirring XBMFlotation MachineCopper Ore Flotation production of caf2 through flotation machines The pulley that drives conveyor belt rotating is called drive pulley or transmission drum Production Of Caf2 Through Flotation Machines Head Pulley As illustrated in Figure 1, tramp–iron contaminated material comes within the pulley’s magnetic field, the tramp iron is attracted and held to the belt until it reaches the underside, passes out of the magnetic field, and is separately discharged The cleaned, nonmagnetic material is discharged over the pulley in a normal trajectoryEriez Magnetic Pulleys

weight of pulley belt conveyor netwerkoostkampbe

Pulley balancing for belt drive systems: is it always Pulley balancing involves adding or removing weight to achieve uniform weight distribution around the axis of rotation, to prevent the pulley from vibrating As a pulley rotates, centrifugal forces act on the pulley, and if its mass is Belt Conveyors for Bulk Materials the loaded conveyor at the design velocity of the belt V, in fpm: (1) To determine the effective tension, T e, it is necessary to identify and evaluate each of the individual forces acting on the conveyor belt and contributing to the tension required to drive the belt at the driving pulleybelt conveyor drive system design pdfSPA SPB SPC SPZ V Belt Pulley Split Taper Bushed Bore Cast Iron VBelt Drive Pulleys 1 2 3 4 5 6 7 8 Grooves, You can get more details about from mobile site on m Source SPA SPB SPC SPZ V Belt Pulley Split Taper Bushed

Timing Belt Pulley Manufacturer Exporter Supplier in

Drive permits smaller pulley size, short centre distance and narrower belt width, as well as horse powertoweight ratio high, reduces space required and also weight of drive Drive provides wide load capacity from sub fractional horsepower to 600HP Flash Flotation Cell The “SubA” Flash Flotation Cell, when installed in the circuit between the ball mill and classifier, makes possible the quick recovery of coarse free mineral, which is a vital factor in economic mill operationSlime losses from overgrinding are reduced to a minimum with the use of the “SubA” Unit Flash Flotation Cell, resulting in increased metallurgical efficiencyFlash Flotation Cell and Flotation Banks 911 Metallurgist Description FX mechanical agitated Continuous Flotation Machine is suitable for continuous flotation test or semiindustrial production test of a small amount of minerals in the laboratory by flotation method It is made up of several units and the number of cells is even Left feed configuration or right feed configuration is available upon requestContinuous Flotation Cell GTEK

China Conveyor Roller manufacturer, Conveyor Pulley

China Conveyor Roller supplier, Conveyor Pulley, Conveyor Frame Manufacturers/ Suppliers Hebei Juming Conveyor Machinery Co, LtdFlotation operation process In the flotation cell or copper ore flotation machine the ore pulp after mixing with the drugs is inflated with air through the stirring XBMFlotation MachineCopper Ore Flotation production of caf2 through flotation machines The pulley that drives conveyor belt rotating is called drive pulley or transmission drum Production Of Caf2 Through Flotation Machines Head DR flotation machines The mining industry has grown Principle of operation and developed over the years The DR flotation machine is the first and has adapted itself to chang mechanical open type machine to incorpoing economic conditions Single cell drive 4) Dual cell drive 5) Length per cell Trellex pulley and roller lagging Flotation Machines DR Automation PDF

Floating Machine – Electro Magnetic Industries

Flotation Machine is applied for rough, fine and sweep separating process of ferrous metals, precious metals, nonmetallic minerals and nonferrous metals such as lead, copper, zinc, molybdenum, gold, etc This series flotation machine is with large inspiratory capacity inflow and low energy consumption Every chute is levelly installed and performs three functions: inhaling air, inhaling ore China VBelt Pulley Spz SPA Spb Spc SPD V Groove Pulley Cast Iron Taper Bore V Belt Pulleys, Find details about China V Belt Pulley, V Groove Pulley Wheels from VBelt Pulley Spz SPA Spb Spc SPD V Groove Pulley Cast Iron Taper Bore V Belt Pulleys Sichuan Mighty Machinery Co LtdChina VBelt Pulley Spz SPA Spb Spc SPD V Groove Drive permits smaller pulley size, short centre distance and narrower belt width, as well as horse powertoweight ratio high, reduces space required and also weight of drive Drive provides wide load capacity from sub fractional horsepower to 600HPTiming Belt Pulley Manufacturer Exporter Supplier in

belt conveyor turn around bend pulle

usa retractable belt pulley system google patentsas the turnaround drum 58 rotates, the veneer 49 is held against and travels with the surface of the turnaround drum 58 by means of holddown belts 66, as shownin their first or normal position in figure 1 as the veneer 49 completes its change of direction, it is conveyed onto lower carrying cables 60, which are supported by pulleys 62 The drilling pulley (1) receives its rotation from drive unit (7) The material to be conveyed is loaded on the belt by one or more feedhoppers (8), mounted over the conveyor belt line, normally places at the tailend sideESSENTIAL COMPONENTS OF BELT CONVEYORS Series RCT permanent magnetic pulley is widely used together with series DT75 and AD80 belt conveyors to replace the drive pulley or driven pulley, and it is especially suitable for the continuous automatic iron separation from steel slag, ore slag, water slag, etc Applications:Series RCT permanent magnetic pulley, magnetic

Conveyor System Solutions Multotec

Multotec’s conveyor system solutions are proven to reduce downtime and belt slippage These conveyor systems include: Multolag™, a direct bond ceramic pulley lagging system that reduces belt slippage on drive and nondrive pulleys MATO conveyor belt systems, including cleaners, clamps, cutters, fasteners and accessories which ensure fewer belt stoppages and downtime The belt tensioning mechanism of claim 5 wherein said spring is operably associated with an arm pivotally supported from said frame and rotatably supporting one of said drive pulley and said driven pulley, said arm being biased by said spring to move said one pulley to exert tension into said drive beltDisc mower with drive belt tightness indicator New