A new modelbased approach for power plant Tube

The mill model is running in parallel with the power plant coal mill operation; the measured and predicted outputs are displayed on the computer screens in the power plant control room When the measured and predicted mill outputs are over the preset threshold values, the system will raise alarm reports to give warning signals plant mill (the mill power draw divided by the mill solids throughput rate), and assumes plug flow and equal residence time of all particle sizes (see later note) The value of E for the torque mill test is the mill energy input divided by the solids load The energy specific cumulative grinding rate at each screen size is calculated from aBall mill media optimization Metcom Tech The power plant has two types of mills: ball mills and attrition mills A ball mill uses steel balls about the size of bowling balls that run in a race (another name for a track) and crush any coal that is in their way! Here are some photos: Balls These are solid steel balls Virtual Tour of the MSU Power Plant

Ball Mill Design/Power Calculation LinkedIn

Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) Balls are added periodically to the mill on a per shift basis or when the power draw drops below a preset value at nominal operating conditions SmartGrind was installed on Mill No5 and its performance was compared to the neighboring Mills 3 and 4Advanced Controller for Grinding Mills: Results from a Coal Mills in thermal power plant Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online for thermal powerplant familiarizationCoal Mills in Thermal Power Plant Mill (Grinding

COAL BASED THERMAL POWER PLANTS: COAL MILLS

Normally the ball mill designers use three types of balls with three different diameters These balls reduce in size as the mills operate and so the highest size ball is normally used for recharging In earlier days, most of the ball mills had a single inlet and outlet, but now designers use both ends to feed coal and also for taking out "The Steam power plant at Grane Mill is owned by the Heritage Trust for the North West on whose behalf the Grane Mill Preservation Group volunteers and associates are working to conserve and repair this unique and important heritage asset to give it the long term future it deserves"The power plant GRANE MILL ↑ The Drax gas plant is dead: But other new gas projects are a headache for the COP26 team, Ember, Feb 15, 2021 ↑ Capacity Market, United Kingdom, Mar 1, 2019 ↑ 80 81 82 Development consent granted for Kemsley Paper Mill Combined Heat Power plant, DS Smith website, July 19, 2019Kemsley Paper Mill power station Global Energy

China Ball Mill Balls Manufacturers and Factory

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for Ball Mill Balls, Ceramic Antenna Insulator, 345 Kv Station Post Insulator, Fine Steel Mesh Sheet, Besides, our company sticks to high quality and reasonable price, and we also offer good OEM services to many famous brandssteel grinding balls for mine gold ore power plant ball mill for sale Forged steel balls for ball mill ball mill ball is ball mill equipment grinding material medium, through the ball mill ball ball and material between the collision between the friction produced mill strip effect, important basic parts, especially the precision industrial ball in the national ball mill ball economic steel grinding balls for mine gold ore power plant ball cast iron grinding media for mill , power plant, mine , cement factory Short Description: Chromium cast grinding balls(high chromium cast grinding balls low chromium cast grinding balls)Superior grinding performance:HighChrome grinding media combining a martensitic structure with hard chrome carbides provides the optimum wear China cast iron grinding media for mill , power plant

THE METHOD OF THE BALL MILL LAUNCHING AT NEW PLANT

The mill refilling by grinding balls to 75% of the filling standard Starting and operation of the mill with 75% of its productivity Period – 68 hours; The final step is the mill loading completely to the required standard and the mill operating with the maximum possible amount of powerDepending upon the mill diameter, rotation is normally between 4 to 24 rotations per minute Also the concept is like: bigger the diameter, slower the rotation The mill centrifuge point is called as Critical Speed, and ball mills mostly function at 65% to 75% of the critical speedBall Mills Manufacturer, Ball Mills Supplier, Ball Mills The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power Calculation 911 Metallurgist

Virtual Tour of the MSU Power Plant

The power plant has two types of mills: ball mills and attrition mills A ball mill uses steel balls about the size of bowling balls that run in a race (another name for a track) and crush any coal that is in their way! Here are some photos: Balls These are solid steel balls about a foot in diameter! The powerplant has several sets that they Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns)Ball Mill Design/Power Calculation LinkedIn The plant was built using the most advanced equipment Through the use of modern technologies and cooperation with a number of research organizations, we managed to achieve very high levels of quality in grinding steel balls– the highest in Ukraine – since day oneGrinding Media Grinding Balls Steel Grinding Balls for

Coal Mills in Thermal Power Plant Mill (Grinding

Coal Mills in thermal power plant Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online for thermal powerplant familiarization A new modelbased approach for power plant Tubeball mill condition monitoring and fault detectionq Shen Guoa, Jihong Wanga,⇑, Jianlin Weia, Paschalis Zachariadesb a School of Engineering, University of Warwick, Coventry CV4 7AL, UK bSchool of Electronic, Electrical and Computer Engineering, University of Birmingham, Birmingham B15 2TT, UK article infoA new modelbased approach for power plant Tubeball steel grinding balls for mine gold ore power plant ball mill for sale Forged steel balls for ball mill ball mill ball is ball mill equipment grinding material medium, through the ball mill ball ball and material between the collision between the friction produced mill strip effect, important basic parts, especially the precision industrial ball in the national ball mill ball economic steel grinding balls for mine gold ore power plant ball

Wet Grinding Ball Mill of Energy Saving Mill with

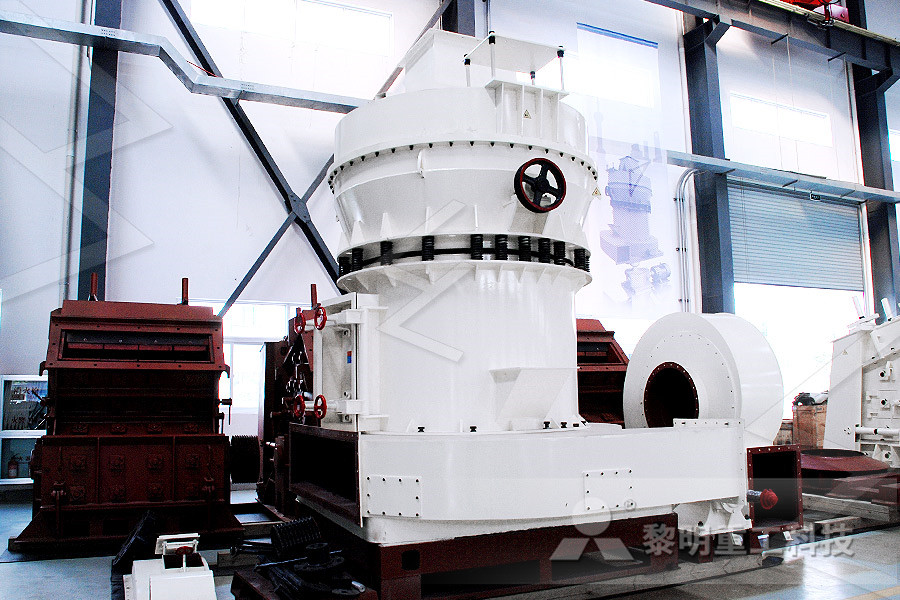

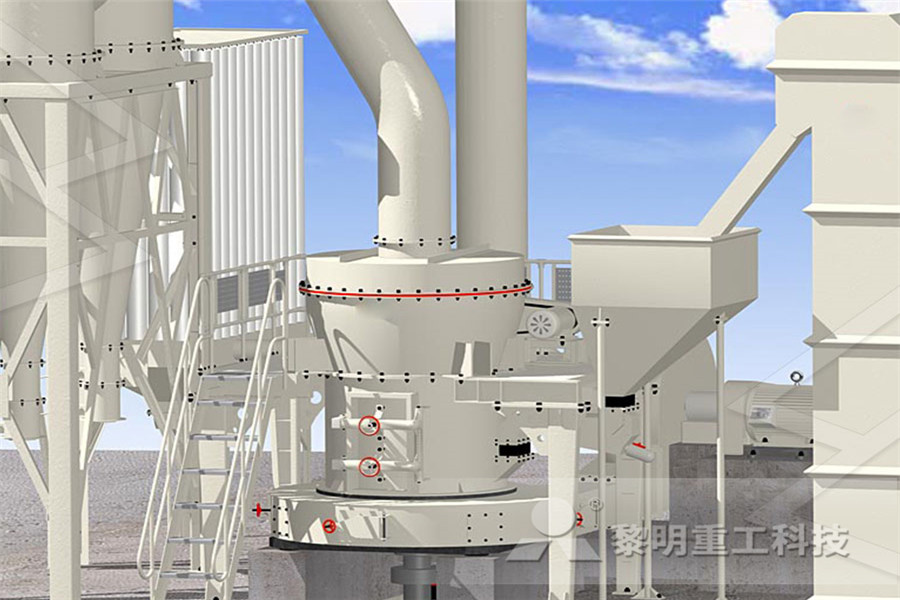

Overview Ball Mill B all mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum ,building material, glass, ceramic, steel slag and fly ash, ect It follows more crushing and less grinding principle to save energy The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by China Low Price Grinding Steel Ball Mill Balls for Ball Mill, Find details about China Grinding Ball, Grinding Media Ball from Low Price Grinding Steel Ball Mill Balls for Ball Mill Shandong Shengye Grinding Ball Co, LtdChina Low Price Grinding Steel Ball Mill Balls for Ball ball mill for power plant The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill Get Price function of ball mill in power plant how many ball tube mill in thermal power plant in india ball mill machine in power plant motocar24pl

in stone damage ball mill in pwer plant

Mill for coal fired power plant coal mill in power plant stone crushing,Grindingcoal ball mill used in power plant Stone Crusher Aggregate In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace Read moreCoal mill is often used in thermal power plant, cement plant, coal fire power plants, etc We grind large pieces of coal into pulverized coal, which produces more energy when burned Therefore, the rotary kilns, boilers and other kiln equipment in these large factories usually use pulverized coal as fuelBall Mill for Sale Mining and Cement Milling EquipmentMSE PRO Bench Top Mini High Energy Vertical Planetary Ball Mill, 04L Size (4 x 100ml or 4 x 50 ml) Designed for holding four 50 ml size milling jars or 100 ml milling size jars (to be ordered separately) Can be placed in a glove box Should not be used in an Ar atmosphere as it can cause arcing due to a 110V voltage power supply to this equipmentPlanetary Ball Mills MSE Supplies LLC

Ball Mill Working Principle And Main Parts

Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionBall mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsBall Mill Eastman Rock Crusher