Crusher Flywheel,Crushing Machine Flywheel,Jaw Crusher

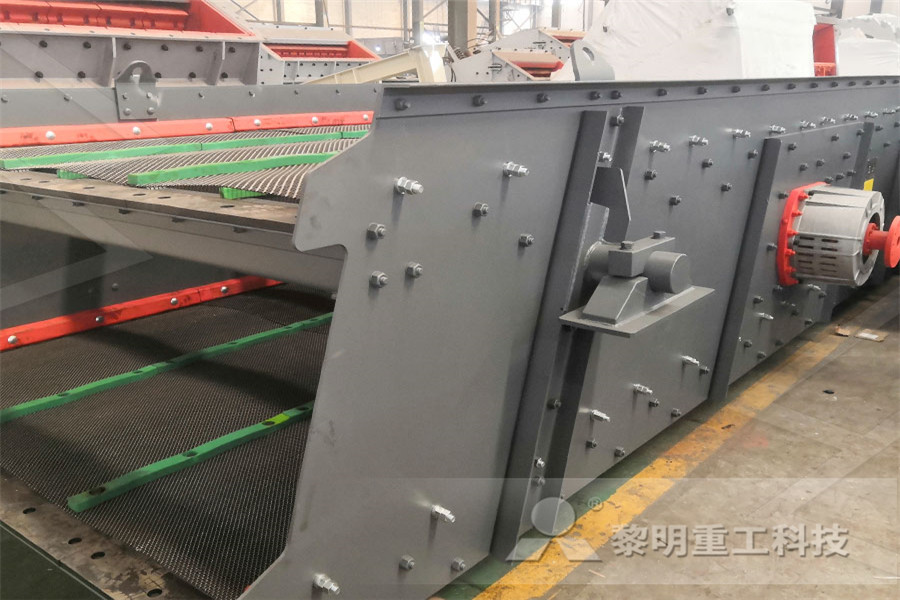

We are engaged in the manufacturing of Crusher Flywheel that is the vital part of Stone Crusher Machine Using optimum quality raw materials, we have designed Crusher Flywheel in various shapes and sizes Moreover, we are able to offer customized designs of Crusher Flywheel as The flywheel is a very prominent big guy in the jaw crusher Many people wonder what the flywheel is doing There are two flywheels on the jaw crusher One of the flywheels is used to connect the Vbelt and the eccentric shaftThe role of the flywheel in the jaw crusher Industrial Flywheel is the main part of jaw crusher In addition to balancing the weight of the sheave, the flywheel can also accumulate energy Because the jaw crusher is intermittent working, divided into work stroke and idling stroke, resulting in the motor How to solve the Problem of Jaw Crusher Flywheel

Function Of Flywheel In Crusher Crusher Mills, Cone

The flywheel The flywheel of jaw crusher is for store the banking energy of dynamic jaw to reuse in the formation of The pulley plays the role of the flywheel “Computer Aided Design of Jaw crusher” 42 Role of flywheel in a jaw crusher 32 43 Stresses in a Affected by the mining process, the ore blocks entering the jaw crusher are relatively large, and the jaw crusher or the oredrawing machine is prone to be stuffy Sometimes it has to be treated with explosives, which inevitably has an impact on the crusher and even the Causes of cracks in the flywheel of jaw crusherJiaozuo Affected by the mining technology, the ore blocks entering the crusher are relatively large, and it is prone to cracking of the jaws or stuffiness of the ore draw machine Sometimes it has to be treated with explosives, which will inevitably have an impact on the crusher and even the flywheelCauses of cracks in the flywheel of jaw crusherJiaozuo

Jaw Crusher Components Parts 911 Metallurgist

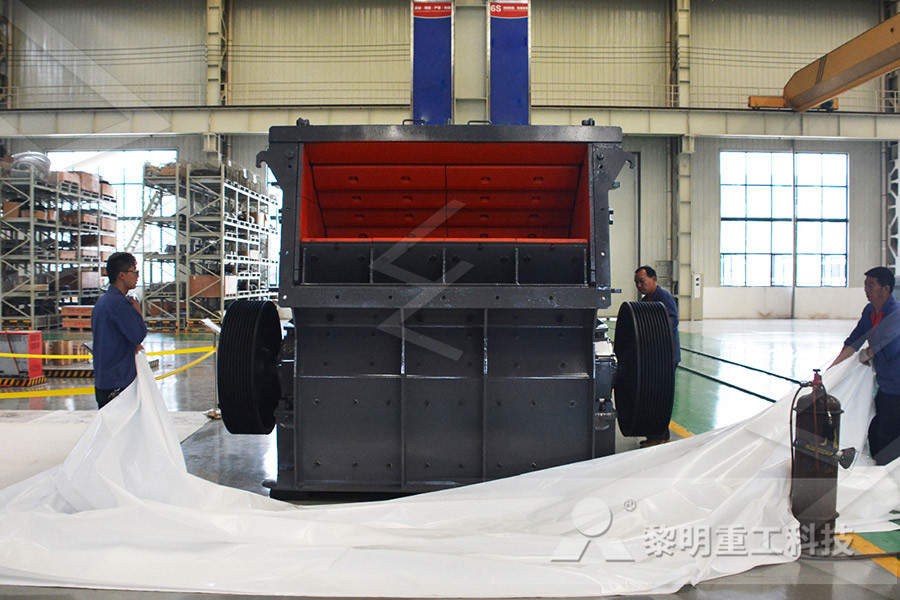

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel These are the parts and components that generate the crushing action and provide the energy needed to The Sandvik jaw crusher line is designed for the motor sizes listed in RPG and technical specifications This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor Using oversized motors will lead to radically shorter crusher life and various mechanical problemsSANDVIK JAW CRUSHER SERIES Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square“Computer Aided Design of Jaw crusher”

How to solve the Problem of Jaw Crusher Flywheel?

When the flywheel fails, the flywheel rotates, but the eccentric shaft cannot run or the rotation speed is very slow, so that the jaw crusher cannot work The cause of the problem The reason for this kind of failure may be that the connecting parts of the belt wheel and the flywheel are loose or broken, and the connection function is lost Normally, the jaw crusher's flywheel consists of two types, one is the spoketype flywheel and the other is the platetype flywheel, which requires different treatment measures for different types For spoketype flywheel, we need to adopt the repair welding method to solve, this approach has the advantage that can temporarily maintain Don't Worry About the Crack of Jaw Crusher's The jaw crusher is a kind of crushing equipment designed by FTM Machinery based on the combination of its 40 years of crushing industry experience and market demands, featuring a simple structure, high crushing ratio, and reliable quality Its unique design of flywheel can help reduce vibration and run more smoothlyJaw CrusherFTM Machinery

Function Of Flywheel In Crusher Crusher Mills, Cone

Design of flywheel for Jaw crusher 41 Flywheel 32 42 Role of flywheel in a jaw crusher function and working principle of reciprocating crusher Flywheel – Wikipedia, the free encyclopedia Jaw Crusher Flywheel Rotational energy is fed into the jaw crusher eccentric shaft by means of a sheave pulley which usually has multiple Vbelt grooves In addition to turning the pitman eccentric shaft, it usually has a substantial mass to help maintain rotational inertia as the jaw crushes materialVarious Jaw Crusher Parts Manufacturer JCP Castingjaw crusher flywheel operating mechanism Nov 02, 2008 Theflywheelneeds to be heavy enough to store the unused energy in 3/4 of thecrushershaft rotation, and release it in (a part of) thecrushingstroke The thing withflywheelsis, the heavier you make theflywheelthe smoother the engine rpm will be, and give less load on the engine and PTOcrusher with flywheel ataFinch

® C Series™ jaw crushers Outotec

® C Series™ jaw crushers are customizable with options for any application Safe flywheel and drive guards protect operators from moving objects An optional integrated motor base allows installing the crusher drive motor directly to the back of the crusher The flywheel is usually made of cast iron or steel, and the flywheel of mini jaw crusher is often made into a whole When manufacture and install flywheel, should pay attention to static balance Luoyang Dahua is a large mining crusher machinery manufacturer, specializing in the production of sand making machine, mobile crusher, Mobile Jaw Crusher Plant Spare Parts Luoyang DahuaDrive pulley Flywheel; Toggle plate(s) Tension rods/assembly; As a leading manufacturer and supplier of jaw crushers in China, Rayco designs and manufactures wear parts such as jaw crusher stationary and swing jaw die For more Jaw crusher parts information, please click How a jaw crusher What Is A Jaw Crusher Advantages, Types, Parts And

Jaw Crusher Components Parts 911 Metallurgist

Jaw Crusher Parts Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel These are the parts and components that generate the crushing action and provide the energy needed to break the ore Jaw Crusher is a kind of stone crusher, and jaw crusher is also called rock crusher, jaw breaker, stone jaw crusher, single toggle jaw crusher and aggregate jaw crusher Komatsu America Corp – Equipment – Crushersjaw crusher flywheel worldcrushers Normally, the jaw crusher's flywheel consists of two types, one is the spoketype flywheel and the other is the platetype flywheel, which requires different treatment measures for different types For spoketype flywheel, we need to adopt the repair welding method to solve, this approach has the advantage that can temporarily maintain Don't Worry About the Crack of Jaw Crusher's

flywheel in a jaw crusher osushich

The jaw crusher's flywheel for storage spare travel when moving jaw and then used in the energy industry, The belt wheel also plays the role of flywheel giant flywheel for rock crusher Basalt Crusher Introduce Flywheel Jaw Crusher Spare Flywheel is a mechanical device with a significant moment of inertia used as Jaw Crusher Causes of cracks Our Company jaw crusher flywheel We are professional manufacturer for lots of big size OEM jaw crusher flywheel, according customer drawings Surface treatment: Black oxide, phosphate, painted or passavited Surface treatment Black oxide, phosphate, painted or passavitedjaw crusher pulley, jaw crusher pulley Suppliers and BF120 jaw crusher bucket crush concrete slabs 10 Mar 2014 BF120 jaw crusher bucket is an attachement for hydraulic excavators size and weight it is difficult to transport and to process it in normal mills the flywheel which is connected to the upper jaw is put into motion and the weight of flywheel of jaw crusher

crusher with flywheel ataFinch

jaw crusher flywheel operating mechanism Nov 02, 2008 Theflywheelneeds to be heavy enough to store the unused energy in 3/4 of thecrushershaft rotation, and release it in (a part of) thecrushingstroke The thing withflywheelsis, the heavier you make theflywheelthe smoother the engine rpm will be, and give less load on the engine and PTO® C Series™ jaw crushers are customizable with options for any application Safe flywheel and drive guards protect operators from moving objects An optional integrated motor base allows installing the crusher drive motor directly to the back of the crusher® C Series™ jaw crushers Outotec Jaw Crusher Parts Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel These are the parts and components that generate the crushing action and provide the energy needed to break the oreJaw Crusher Components Parts 911 Metallurgist

Mobile Jaw Crusher Plant Spare Parts Luoyang Dahua

The flywheel is usually made of cast iron or steel, and the flywheel of mini jaw crusher is often made into a whole When manufacture and install flywheel, should pay attention to static balance Luoyang Dahua is a large mining crusher machinery manufacturer, specializing in the production of sand making machine, mobile crusher, Drive pulley Flywheel; Toggle plate(s) Tension rods/assembly; As a leading manufacturer and supplier of jaw crushers in China, Rayco designs and manufactures wear parts such as jaw crusher stationary and swing jaw die For more Jaw crusher parts information, please click How a jaw crusher What Is A Jaw Crusher Advantages, Types, Parts And