The Reason of Ball Mill’s Uneven Discharging Silicon

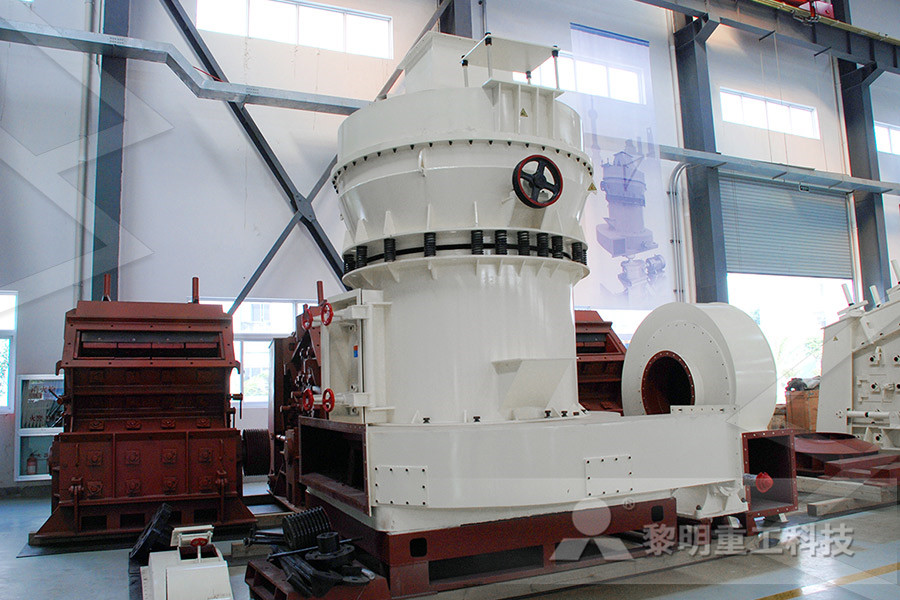

Grinding the material evenly or not seriously affects the production efficiency of ball mill Uneven ball mill’s discharging may be caused by the following two aspects: Firstly, the feeding grinding materials cause the uneven discharging When water into the grinding material is high, it may cause the ball mill grinding “full” phenomenon Grinding the material evenly or not seriously affects the production efficiency of ball mill Uneven ball mill’s discharging may be caused by the following two aspects: Firstly, the feeding grinding materials cause the uneven discharging When water into the grinding material is high, it may cause the ball mill grinding "full" phenomenonThe Reason of Ball Mill’s Uneven Discharging Peripheral Discharge Ball Mills The several layers of balls lying on top of those next to the shell follow a similar cycle except that, due to relative difference in the two forces, their paths become more nearly vertical The outer layers, spreading more than the inner layers, increase the area in the zone of the falling ballsPeripheral Discharge Ball Mills Theory and Practice

grate discharging ball mill, grate discharging ball mill

There are 40 suppliers who sells grate discharging ball mill on Alibaba, mainly located in Asia The top countries of supplier is China, from which the percentage of grate discharging 8 行 Excellent for dry wet fine grinding , mixing, reacting of colour paints, emulsifiers, Ball Mill, Dry Grinding Ball Mill, Micro Ball Mills Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes The main part of the ball mill mainly include feeding part, discharging part, a rotary part, a transmission part Ball Mill Working Principle And Main Parts

Ball Mill EasyStudyPoint

The ball mill machine is wide accustomed method cement, salt product, building material, refractory material, fertilizer, ceramics, and glass, etc The ball mill, also known as the rod mill, will work in a dry manner or wet way you choose the operating way of a little ball mill machine according to your material and discharging way35 行 Ball mill machine can be used to grind various ores and other Ball Mill/Ball Mills/Grinding MillsFote MachineryGrinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical mechanical and chemical characteristics Typical examples are the various ores minerals limestone etc The applications of ball mills center discharging rod grinding mill for mineral process

grate discharging ball mill, grate discharging ball mill

Alibaba offers 830 grate discharging ball mill products A wide variety of grate discharging ball mill options are available to you, such as local service location, applicable industries, and warranty Grate Discharge Ball Mills have shown 25% to 45% more tonnage ground and a substantial reduction in power consumed per ton of material compared size for size with overflow mills To illustrate the characteristics of various type mills we have shown the types of discharge for rod mills and ball mills There are essentially four types of rod mill Overflow VS Grate Discharge Ball or Mill Why RetrofitMechanical ball mills With mechanical ball mills, material is discharged mechanically through a discharging box The material is usually further conveyed to a dynamic separator, which together with the mill forms a mechanical ball mill grinding plantBall mills PSP Engineering

Mechanical ball mills PSP Engineering

Mechanical ball mills With mechanical ball mills, material is discharged mechanically through a discharging box The material is usually further conveyed to a dynamic separator, which together with the mill forms a mechanical ball mill grinding plant These grinding plants are used to comminute relatively dry materials to a very high fineness The ball mill machine is wide accustomed method cement, salt product, building material, refractory material, fertilizer, ceramics, and glass, etc The ball mill, also known as the rod mill, will work in a dry manner or wet way you choose the operating way of a little ball mill machine according to your material and discharging wayBall Mill EasyStudyPointWith a few design changes, dry discharging is simple and contained The main design change is the addition of a full or partial housing to contain the solids as they are discharged from the mill while rotating Dry discharging is fast – usually 515 minutes Small mills utilize a Milling Discharging Paul O Abbe

Ball Mill Loading Wet Milling Paul O Abbe

Ball Mill Loading Wet Milling Ball Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of productBall mill introduction The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc Ball mill can grind various ores and materials with dry type or wet typeSand Ball Mill, For Industrial, Rs /piece Laxmi A ball mill, a type of grinder , is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding mediumBall Mills SolidsWiki

Ball Mills vs Rod Mills How To Choose Ball Mill or

The discharging fineness of the material milled by ball mill is between 007404mm, and that of the material milled by rod mill is between 08330147mm 6 Running Cost The power consumption of the ball mill is slightly higher than that of the rod mill, and the wear rate is also higher than that of the rod millchemical and cement industry small ball mill with best Relationship Between Ball Mill and Cement Industry Essay There are two kinds of ball mills, grate type and overfall type due to different ways of discharging materialIn the international cement market, taking into account of both the cement process and quality requirements at the same time, ball mill is the best choice for producing high quality grate discharging ball mill with ceWith a few design changes, dry discharging is simple and contained The main design change is the addition of a full or partial housing to contain the solids as they are discharged from the mill while rotating Dry discharging is fast – usually 515 minutes Small mills utilize a Milling Discharging Paul O Abbe

Ball mills PSP Engineering

Mechanical ball mills With mechanical ball mills, material is discharged mechanically through a discharging box The material is usually further conveyed to a dynamic separator, which together with the mill forms a mechanical ball mill grinding plantMechanical ball mills With mechanical ball mills, material is discharged mechanically through a discharging box The material is usually further conveyed to a dynamic separator, which together with the mill forms a mechanical ball mill grinding plant These grinding plants are used to comminute relatively dry materials to a very high finenessMechanical ball mills PSP Engineering Ball Mill SCREW FEEDING Excellent for dry wet fine grinding , mixing, reacting of colour paints, emulsifiers, enamels, refractoriies etc Micro Ball Mills are provided with twin mouths for charging dischargingBall Mill, Dry Grinding Ball Mill, Micro Ball Mills

Ball Mill EasyStudyPoint

The ball mill machine is wide accustomed method cement, salt product, building material, refractory material, fertilizer, ceramics, and glass, etc The ball mill, also known as the rod mill, will work in a dry manner or wet way you choose the operating way of a little ball mill machine according to your material and discharging wayThe overflow ball mills discharging speed is lower than that of grid ball mills As a consequence, the capacity of the former is smaller than that of the latter, about 10% to 15%Advantages and Disadvantages of Overflow Ball Mills Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes The main part of the ball mill mainly include feeding part, discharging part, a rotary part, a transmission part Ball Mill Working Principle And Main Parts

Ball Mills SolidsWiki

A ball mill, a type of grinder , is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding mediumThe discharging fineness of the material milled by ball mill is between 007404mm, and that of the material milled by rod mill is between 08330147mm 6 Running Cost The power consumption of the ball mill is slightly higher than that of the rod mill, and the wear rate is also higher than that of the rod millBall Mills vs Rod Mills How To Choose Ball Mill or