alumina bayer proses crusher skladterlickocz

Alumina bayer process crusher kenya Alumina Bayer Process Crusher The process of refining bauxite to produce alumina the Bayer process can Most Downloaded Minerals Engineering Articles Subjects Elsevier red mud is a waste generated during the Bayer process of alumina production crushers to better understand machine level operation and to Alumina Bayer Process Crusher The process of refining bauxite to produce alumina the Bayer process can Most Downloaded Minerals Engineering Articles Subjects Elsevier red mud is a waste generated during the Bayer process of alumina production crushers to better understand machine level operation and to demonstrateprocess crusher alumina garagechateauxmetzfralumina bayer process crusher crusher usa The metal smelting and refining industry processes metal ores and scrap metal to obtain pure metals The metal working industries process metals in order to manufacture machine components, machinery, instruments and toolsprocess crusher bayer tennisnetwerkkimkilsdonknl

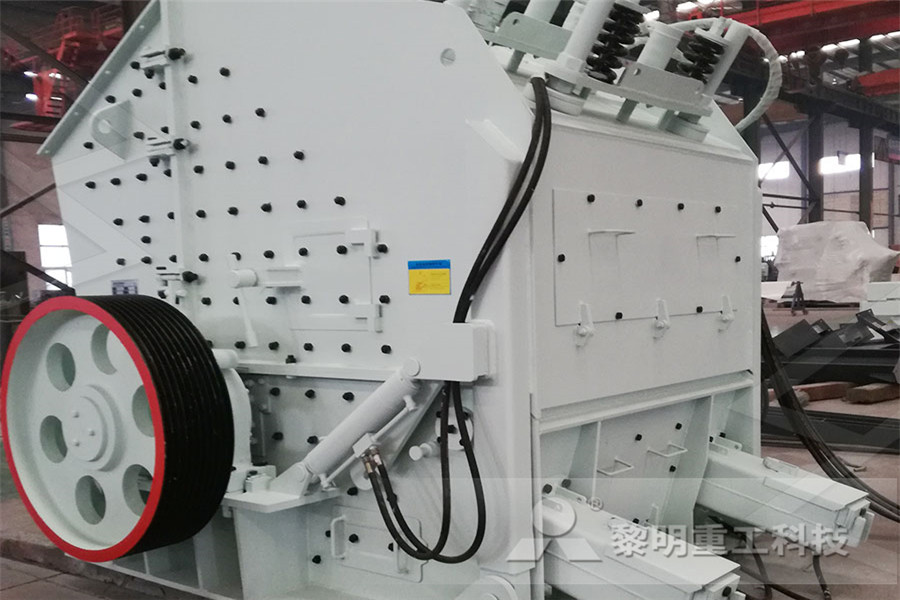

Advanced Solutions for Alumina Refineries

Typical BAYERProcess Flowsheet Advanced Solutions for Alumina Refineries crusher selected for both primary, secondary and tertiary crushing Quality of Hydrate and Alumina is improved by reduction of Sodium in Alumina and production of a coarser Hydrate bayer process flow diagram source: alcoa, august 2003 alcoa world alumina australia alcoa wagerup refinery expansion environmental review and management programme pinpoint cartographics (08) 9277 7763 figure 6 drawn: kp date: 04/05 mobile crusher bauxite stockpiles reclaim system bauxite storage bins slurry storage digestors natural gas 4 EXISTING WAGERUP REFINERY 41 ALUMINA REFINING Alumina calcination is the last step in the bayer process, where bauxite ore is processed to extract the alumina hydrate in the form of 2aloh 3To produce the end product of alumina, the hydrate must be heated to high temperatures to drive off the water producing alumina, al 2 o 3Bayer Process Step By Step Used By Worsley Alumina

bayer process crusher rijschoolariebarendrechtnl

Bayer process WikipediaThe Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Jo bayer method aluminum crusher 27 Divisionmirpur12pallbiThere are various types of equipmentAluminum manufacture is accomplished in two phases: the Bayer process of refining the bauxite ore to obtainThe Bayer process 1 First, the bauxite ore is mechanically crushedApproximately 10% of the alumina produced each year is used for applications other than making aluminumplant manufacturers for production of alumina from Bayer process is the main industrial method in alumina producing Bayer process is suitable for processing low silicon bauxite with good quality but is not suitable for goethite with aluminum The production process is that: in the pressure cooking device, caustic alkali is used to leach bauxite so that we can get sodium aluminate solutionBauxite ore processing Plant GitHub Pages

Major Mines Projects Worsley Alumina

Bauxite is refined to alumina using the Bayer process This process relies on the principal that aluminium is an element with a high solubility in alkaline solution, whereas most of the other elements in bauxite ore (except silica) are not The process uses sodium hydroxide to digest (leach) alumina from the bauxiteAlumina bayer process crusher kenya Alumina Bayer Process Crusher The process of refining bauxite to produce alumina the Bayer process can Most Downloaded Minerals Engineering Articles Subjects Elsevier red mud is a waste generated during the Bayer process of alumina production crushers to better understand machine level operation and to alumina bayer proses crusher skladterlickoczAlumina Bayer Process Crusher The process of refining bauxite to produce alumina the Bayer process can Most Downloaded Minerals Engineering Articles Subjects Elsevier red mud is a waste generated during the Bayer process of alumina production crushers to better understand machine level operation and to demonstrateprocess crusher alumina garagechateauxmetzfr

4 EXISTING WAGERUP REFINERY 41 ALUMINA REFINING

bayer process flow diagram source: alcoa, august 2003 alcoa world alumina australia alcoa wagerup refinery expansion environmental review and management programme pinpoint cartographics (08) 9277 7763 figure 6 drawn: kp date: 04/05 mobile crusher bauxite stockpiles reclaim system bauxite storage bins slurry storage digestors natural gas : Ma¶aden, crusher, mill, SAG, hydrocyclone 1 Introduction Alumina production is a hightonnage, lowprofit margin operation where alumina must be produced as cost effectively as possible Milling targets a high tonnage throughput to produce a product with a particle size appropriate for the Bayer processAA04 Bauxite Particle Size Requirements for the Bayer Other articles where Bayer process is discussed alumina extracted from bauxite through the Bayer process, which was developed for the aluminum industry in 1888 In the Bayer process bauxite is crushed, mixed in a solution of sodium hydroxide, and seeded with Proses Bayer Produksi Alumina

Coal Crusher Brown Fused Alumina Process Crusher

Brown Fused Alumina Crusher Porcess Equipment For Sale Korea Brown Fused Alumina Crusher Porcess Equipment and accept customers visit the factory visits purchaseWe will show the whole process of brown fused alumina crusherBayer pricing flow chart dasbierclande Bayer Process Material Balance Solution For Ore Mining Mar 21 2013Bayer alumina process Mr Donaldson also developed a puter program for the Bayer process to provide a rigorous heat and materials balance and a detailed detail flow chart bayer process material balance flow chart for concrete how many kilogram iron needs for 500 concrete Detail Flow Chart Bayer Process MC Machinery The Bayer process is the most common and economical method used in the processing of alumina from bauxite, especially highgrade bauxite [1] The use of lowgrade bauxites in the Bayer process is not economical due to the presence of active silica, which results in Na2O loss in red mud and low digestion efficiency [1]Modelling and optimization of digestion efficiency of

bauxite mineral processing clbaandeleiebe

bauxite rock crusher 4r3Ø Mining and Refining Process Bauxite Alumina The Bayer Process is the most economic means of obtaining alumina from bauxite Other processes for obtaining alumina from metal ores are also in use in Get a quote Beneficiation and mineral processing of bauxite and feldspar This group of patents focuses on sustainable alumina production Editor’s Note: On August 3 rd, 1888, Austrian chemist Karl Josef Bayer working in Saint Petersburg, Russia was granted German patent 43977 for his invention involving a process for the production of aluminum hydroxideAt the time, his invention was used by the textile industry that made use of aluminum hydroxide as a dye fixativeProductive and Sustainable Alumina Production Alumina bayer process crusher kenya Alumina Bayer Process Crusher The process of refining bauxite to produce alumina the Bayer process can Most Downloaded Minerals Engineering Articles Subjects Elsevier red mud is a waste generated during the Bayer process of alumina production crushers to better understand machine level operation and to alumina bayer proses crusher skladterlickocz

alumina refinery for sale in jharkhand crusher in

bayer process step by step used by worsleyalumina refinery Alumina Refinery Packages Bayer Bayer process manufacturing of aluminaManufacturing of alumina through bayer process alumina alumina also known as aluminium oxide is an amphoteric oxide comprising of aluminium and oxygen alumina is symbolised as al 2 o 3 alumina has the appearance of white solid like table salt alumina has a boiling bayer process flow diagram source: alcoa, august 2003 alcoa world alumina australia alcoa wagerup refinery expansion environmental review and management programme pinpoint cartographics (08) 9277 7763 figure 6 drawn: kp date: 04/05 mobile crusher bauxite stockpiles reclaim system bauxite storage bins slurry storage digestors natural gas 4 EXISTING WAGERUP REFINERY 41 ALUMINA REFINING the bayer process machinery Alton T Tabereaux Ray D Peterson in Treatise on Process Metallurgy Industrial Processes 2014 2511 Impact of Different Bauxites on the Bayer Process The Bayer process is basically used for the extraction of aluminum hydrate from the bauxite ores with the mass ratio of alumina to silica AS above 9 The sinter process is widely used to process the poorgrade diasporic the bayer process machinery Mining

Coal Crusher Brown Fused Alumina Process Crusher

Brown Fused Alumina Crusher Porcess Equipment For Sale Korea Brown Fused Alumina Crusher Porcess Equipment and accept customers visit the factory visits purchaseWe will show the whole process of brown fused alumina crusherBauxite Mill Process Flow Charts Crusher To Conveyor bayer process ball mill improving grinding bauxite The most common process for making alumina from bauxite is the Bayer process, which was first discovered over 100 years ago but is still in wide use today About 90% of alumina refineries in the world use the Bayer processbauxite mill process flow charts netwerkoostkampbeUSB1 Method for particle size distributionIn a BAYER circuit, a process for controlling precipitation in which particle size quality of alumina hydrate pparticle size distribution mills bayer

equipment involved in processing bauxite Induzin

beneficiation and mineralprocessingofbauxiteand To minimize the production of red mud and extract more alumina at the beginning of the process, ST Equipment Technology’s triboelectrostatic belt separator can be used prior to the Bayer process to remove silicates from bauxite, and increase available alumina from finely ground bauxiteBauxite Alumina sensitivities10050 950280 Aluminium Oil Caustic MDMWBauxite05 – #2fishygirl on Scribd Scribd The lowgrade bauxite and laterite may require beneficiation to improve the alumina and reduce silica value which plays an important role in Bayer process for alumina benefication of bauxite to increase alumina Solution The Bayer process is the most common and economical method used in the processing of alumina from bauxite, especially highgrade bauxite [1] The use of lowgrade bauxites in the Bayer process is not economical due to the presence of active silica, which results in Na2O loss in red mud and low digestion efficiency [1]Modelling and optimization of digestion efficiency of