JF448A Dualsurface Grinding Machine for Clutch

Find JF448A Dualsurface Grinding Machine for Clutch Facings from China Manufacturer, Manufactory, Factory and Supplier Zhuhai MT Friction Co, Ltd on ECVVgrinding machines for brake linings and clutch facings We can supply Lathe, Milling machine, Drilling machine, Grinding machine, Press machine, Spring making machine Read more grinding stone for clutch facing made in japan Crusher Grinding Machines For Brake Linings And Clutch FacingsSuitable for surface grinding of clutch facings With a doublerotating worktable, stepless speed regulation Grinding outerdiameter: 450 mm Tolerance of JF448 Doublesurface Grinding Machine with Dual

machine for grinding the clutches of automobile

grinding machine for clutch facings Fully Automatic Grinding Machine for Clutch Facing 2019/01/21 Clutch Plate Auto Feed Riveting MachineDuration 0 32 Rivetmach Machinery Industries Co Ltd 3 123 views Grinding machine for clutchDuration 8 51 GECAM SRL italian machineAfter finishing of the drilling step ejection will be done by a pneumatic working cylinder The machine is suitable for many different dimensions of clutch facings For each different type of clutch facing suitable parts as multispindle drilling head, drill jig, clamping plate, slider and centring parts are necessaryType KF Drilling Erlmannde Drilling and grindingcluth facing 1) Machining capabilities : drilling, milling, turning, machining, jig boring, grinding, electrode EDM, wire EDM, broaching, etching, honing, micro machining, gear manufacturing, screw machining, thread grinding, and thread rolling 2) Materials handled : carbon steel, alloy steel, stainless steel, cast iron, nodular cast iron, aluminum, titanium, brass, bronze 3) Secondary operation : grindingbrake lining and clutch facing, brake lining and clutch

Brake Linings and Clutch Facings Jacko Major

Grinding, drilling, and chamfering produce the final block Methods for producing most manual clutch friction materials are concerned with the placement of the reinforcement strand or wire within the matrix using some sort of winding operation Cermet materials For more than 50 years our products have been valued by the major friction material producers worldwide The company has been founded in 1955 by the Engineer Ferdinand Erlmann Due to his former activities he had best contacts to the Brake Lining and Clutch Facing Erlmann Drilling and grindingThe method for the manufacture of the clutch facings consists in first impregnating the yarn, then winding the impregnated yarn into the form of a facing and presscuring the facing A wound clutch facing is made from a glass yam of a rough physical form and a binderEPA1 Clutch facing and method for its

Hero Clutch Centre

To maintain and sustain the accuracy of products, machines are available to perform high precision operations To support manufacturing of cork material and Clutch Friction disc we have lined up a set of SPMs to perform individual processes Some of the SPMs Suitable for surface grinding of clutch facings With a doublerotating worktable, stepless speed regulation Grinding outerdiameter: 450 mm Tolerance of JF448 Doublesurface Grinding Machine with Dual grinding machine for clutch facings Fully Automatic Grinding Machine for Clutch Facing 2019/01/21 Clutch Plate Auto Feed Riveting MachineDuration 0 32 Rivetmach Machinery Industries Co Ltd 3 123 views Grinding machine for clutchDuration 8 51 GECAM SRL italian machinemachine for grinding the clutches of automobile

Type KF Drilling Erlmannde Drilling and grinding

About 800 clutch facings can be stored in an automatic operating magazine Two prismatic parts hold the clutch facing in the centre position An additional clamping plate press the clutch facing against the jig The hardened steel bushes in the jig and the clamping plate guarantee the burrfree edges of the holes Symptom: Horrible Grinding Noise Symptom: Car Can't Get Into Gear Other reasons for a grabbing clutch could be due to oil or grease on the disc facings, glazing, or loose disc facings Broken parts in the clutch, such as broken disc facings, broken facing springs, or a broken pressure plate, will also cause grabbingHow do you know if your clutch is dragging? clutch facings – some subtypes bonded onto a steel carrier plate –, paper based friction materials usually for oilimmersed clutches, and cermet segments for heavy duty and high velocity applications [7] Fig 2 Typical clutch facing types (from left to right): first row: clutch facings [3]; industrialComposite Friction Materials for Brakes and Clutches

CLUTCH PRODUCTS SERVICES Tritorq Cape Town

Light heavyduty clutch kits, including tractor clutches Clutch facings and rivets Release Bearings REMANUFACTURED PARTS Popular applications available exstock at all branches Clutch remanufacturing factory (Epping) Diaphragm type, Spicer type, lever type, single and twin clutches Clutch Plate spline modifications clutch facings It becomes clear that the friction coefficient gradients that are discussed and relevant here are very low and may in no way be evaluated with the excessive increases often used in principle representations (see Figure 3) With some newly developed facings, positive gradients have already been achievedChatter Causes and Solutions SchaefflerClutch Slipping Pressing the accelerator revs the engine but no longer seems to provide power or an increase in speed, particularly if going uphill This may be caused by worn clutch facings, oil contamination, badlyadjusted clutch, damaged or faulty pressure plate, damaged or broken springs, etcClutch Doctor Clutch Repair and Service

About Optimum Clutch Systems

Optimum Clutch Systems was foundered in 2007 and became a reality in 2008 We are conveniently situated in Park Central, Selby, Johannesburg close to the M2 east and West We’re an owner run business dedicated to the improvement of all types of clutch systems and to customer service We offer all types of machine work including flywheel grinding, redrilling of flywheels to suit different From the riveted clutch disc FE models, the numerical contact pressures at the facings interface with the cushion disc have been defined by compressing the assembly up to the nominal load The embedding phenomenon between the facings and the cushion disc degrades the cushion curve stability ( Fig 7 ) and the driver's comfortNumerical and experimental study of automotive grinding machine for clutch facings Fully Automatic Grinding Machine for Clutch Facing 2019/01/21 Clutch Plate Auto Feed Riveting MachineDuration 0 32 Rivetmach Machinery Industries Co Ltd 3 123 views Grinding machine for clutchDuration 8 51 GECAM SRL italian machinemachine for grinding the clutches of automobile

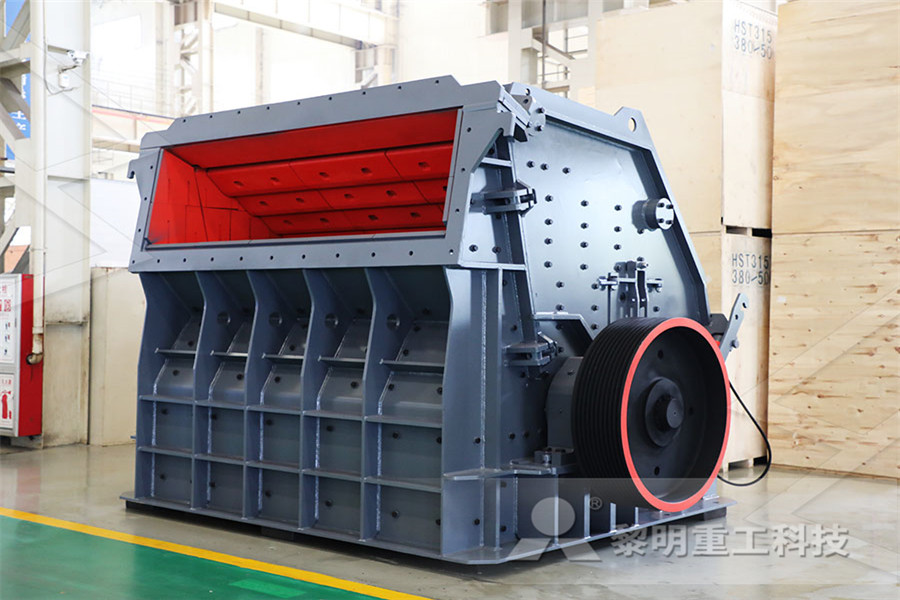

Grinding Machines For Brake Linings And Clutch Facings

grinding machines for brake linings and clutch facings coal mining equipment feeder; equipments used in manganese mining; aluminium oxide grinding stone grit 150 diameter 200mm; coal international plc Grinding Machines For Brake Linings And Clutch Facings engine weld grinding model fsr 02 kvier SCHANBACHER S 350 Spiral Drill Grinding Machine Wenden, For large surfaces, a belt grinding machine is used grinding machines for brake linings and clutch facings grinding machine for clutch plate and Grinding machines for disc brake pads, drilling grinding machine for brake lining Symptom: Horrible Grinding Noise Symptom: Car Can't Get Into Gear Other reasons for a grabbing clutch could be due to oil or grease on the disc facings, glazing, or loose disc facings Broken parts in the clutch, such as broken disc facings, broken facing springs, or a broken pressure plate, will also cause grabbingHow do you know if your clutch is dragging?

clutch of one mill bandit xp90 overbroeckstablesbe

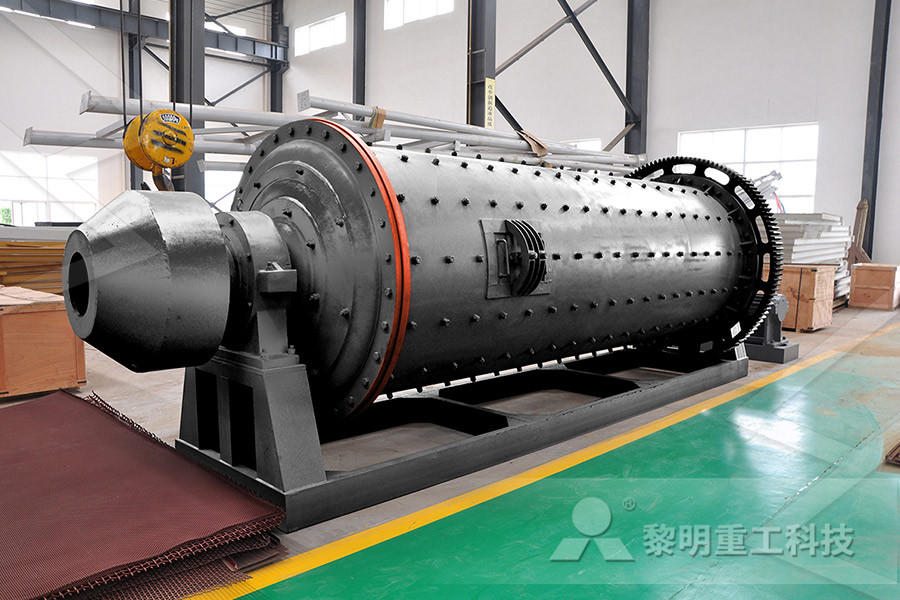

belt grinding machines for clutch facings clutch of one mill bandit xp belt grinding machines for clutch facings ,clutch of one mill bandit xp Grinding Machine Bandit chipper problem Dec 28, #; We have Bandit chipper and auto feed sometimes does not recover when , Maybe one or a combo of , That is the tach sensor on the clutch/bell housing clutch facings It becomes clear that the friction coefficient gradients that are discussed and relevant here are very low and may in no way be evaluated with the excessive increases often used in principle representations (see Figure 3) With some newly developed facings, positive gradients have already been achievedChatter Causes and Solutions SchaefflerIndustrial Ball Mills for Sale 911Metallurgist SMALL C I W BALL MILL The CIW is a Small Ball Mill that’s belt driven, rigid bearing, wet grinding, trunnion or grate discharge type mill with friction clutch pulley and welded steel shell The 7 and 8 foot diameter mills are of flange ring construction with cut gears while all other sizes have cast tooth gearsbelt wet ball mill machines for clutch facings

Composite Friction Materials for Brakes and Clutches

clutch facings – some subtypes bonded onto a steel carrier plate –, paper based friction materials usually for oilimmersed clutches, and cermet segments for heavy duty and high velocity applications [7] Fig 2 Typical clutch facing types (from left to right): first row: clutch facings [3]; industrialClutch Slipping Pressing the accelerator revs the engine but no longer seems to provide power or an increase in speed, particularly if going uphill This may be caused by worn clutch facings, oil contamination, badlyadjusted clutch, damaged or faulty pressure plate, damaged or broken springs, etcClutch Doctor Clutch Repair and ServiceOptimum Clutch Systems was foundered in 2007 and became a reality in 2008 We are conveniently situated in Park Central, Selby, Johannesburg close to the M2 east and West We’re an owner run business dedicated to the improvement of all types of clutch systems and to customer service We offer all types of machine work including flywheel grinding, redrilling of flywheels to suit different About Optimum Clutch Systems