Coal Mills in Thermal Power Plant Mill (Grinding

Coal Mills in thermal power plant Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online for thermal powerplant familiarization Coal Mill Model In Thermal Power Plant Pulverised coal preparation system Coal mills is the heart of coalfired power plants The complex nature of a milling process together with the complex interactions between coal quality and mill conditions would lead to immense difficulties for obtaining an effective mathematical model of the milling processCoal Mill Model In Thermal Power Plant 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner Coal mill pulverizer in thermal power plants

coal mill in thermal power plant Induzin

thermal power plants coal hangup in bowl mills Aug 29, 2010 Coal Hangup in Bowl Mill: Depending on the quality of the coal, sometimes the smooth flow to the coal mill can be disrupted The mill will then trip on flow protection, upsetting boiler parameters and demanding immediate operator corrective actionCoal mill pulverizer in thermal power plants 17112012 coal mill/pulverizer in thermal power plants shivaji choudhury 2 1Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form Pulverized coal Thermal power station and race mill in thermal power plant The power consumed by the mill per ton of coal ground is only twothirds of the ball mills However if the primary air fan power is also taken into account, in the case of a pressurized mill the power consumption is lower only by about 15%COAL BASED THERMAL POWER PLANTS: COAL MILLS

THERMAL POWER PLANTS: COAL HANGUP IN BOWL

Bowl mills are used for pulversing coal in pulverized coal fired boilers The coal to the mill is fed by a coal feeder from the coal bunker There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode, the chain link feeder, the drag feeder, etc Row coal from the yard is sized in crushers and stored in coal bunkers 3 Thermal power plant technology – Flexibility and comparison of generation technologies 33 31 Fundamentals of thermal power plant design and operation 34 32 Operational flexibility 42 33 Comparison of flexibility parameters in different generation technologies 46 4 Retrofits to increase flexibility of coalfired power plants –Flexibility in thermal power plants Agora Energiewende Among thermal based power generation, coal based power plants are highest in: Air pollution, Waste generation ,Water consumption ,Emission of mercury ,Greenhouse emission Impact of Thermal power plant on water source Water Intensive New thermal power plant of 500 MW installed capacity requires – around 14 million m3 of water per annumEnvironment Impact Assessment of Thermal Power Plant

List Of Coal Mill In Thermal Power Plant Crusher Mills

InService Inspection For Coal Handling Plant Of Thermal In the thermal power plants maximum requirements of fuel is a coal From the bunker the coal flows through coal mills to boiler furnace coal mill, Coal mill maintenance, coal grinderCoal mill overhauling works Thermal power plant Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating stationCoal handling plant in a thermal power generating

Coalmill optimisation in coalfired power stations

[6] P Niemczyk: “Improved coal grinding and fuel flow control in thermal power plants”, 18th IFAC World Congress, Milano, 28 August to 2 September 2011 [7] P Pradheepa, et al: “Modeling and Control of Coal Mill”, Tenth IFAC International Symposium on Dynamics and Control of Process Systems, Mumbai, 18 to 20 December 2013 Vertical Coal Mill On the basis of retaining the advantages of RP grinders, the innovative HP mediumspeed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders Its grinding parts have a long service life and are easy to replace Ball Grinding Mill Dual inlet dual outlet steel ball mills have advantages of high rate of Coal Mill Coal Fired Power Generation Shanghai 3 Thermal power plant technology – Flexibility and comparison of generation technologies 33 31 Fundamentals of thermal power plant design and operation 34 32 Operational flexibility 42 33 Comparison of flexibility parameters in different generation technologies 46 4 Retrofits to increase flexibility of coalfired power plants –Flexibility in thermal power plants Agora Energiewende

What Is Thermal Power Plant? Types Components

When such power plants use coal as a primary energy source for generating power is called Coalfired plants or thermal power plants Types of Power Plants Based on Uses: Power plant can be classified depending on commercial use, and the following types of power plants are observed in India Thermal power plant 杭州汽轮机股份有限公司 PRODUCT DETAILS Indian 150MW steam turbine generator IND BARATH COAL BASED THERMAL POWER PLANT is located in Tuticorin, India 2 sets of 150MW doublecasing reheat mode steam turbines wereThermal power plant HTC Turbine power plant to another However, current coalfired power generation is in competition with renewable energy and thus generation has shifted in many countries from baseload to load following mode necessitating flexibility in power plant operations As such, frequent cycling of coalfired power plants can cause thermal and pressure stressesOperating ratio and cost of coal power generation

Power Plant Spares Encotec Energy (India)

The company has set up a 2 x 600 MW thermal power plant at Mutiara in the district of Tuticorin, Tamil Nadu, India The plant uses desalinated water for its operation and is fueled with coal from Indonesia Encotec has been entrusted with the supply of required spare parts for power plant equipment Encotec services at a glance:InService Inspection For Coal Handling Plant Of Thermal In the thermal power plants maximum requirements of fuel is a coal From the bunker the coal flows through coal mills to boiler furnaceList Of Coal Mill In Thermal Power Plant Crusher Mills Coal mill pulverizer in thermal power plants Nov 17, 2012 3 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the coal mill in power plant klepvalvescoza

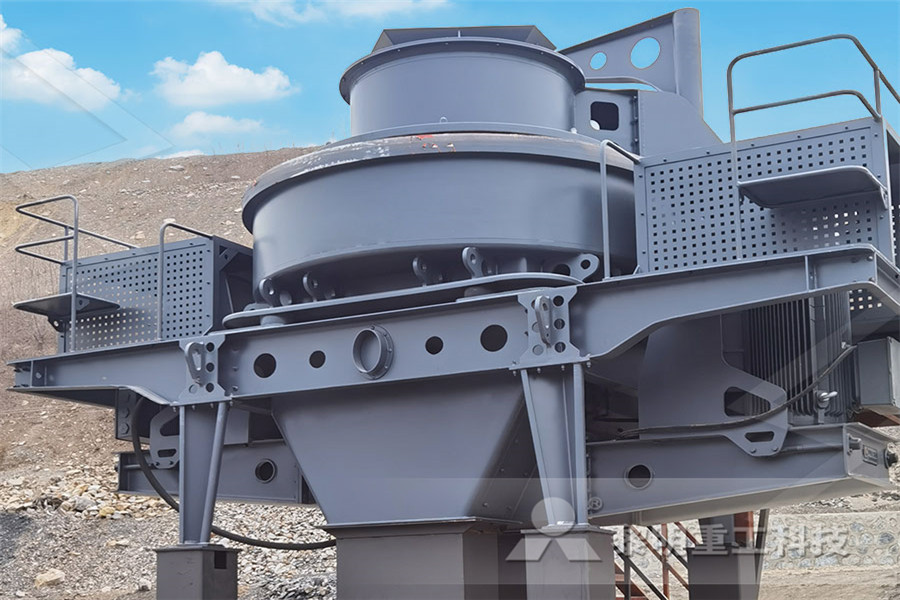

Coal Mill Of A Thermal Power Plant Stock Photo

Photo about Coal mill of thermal power plant, UP, India Image of thermal, massive, power Coal Mill Thermal Power Plant insurancewyr Coal Mill Thermal Power Plant In the mining industry, we have accumulated rich practical experience, which can provide users with a set of solutions free of charge spiral Bread Cake Pastry Pita Pizza Crossiant Spiral Cooling Conveyor System Get Price [] Modeling and Control of Coal Mill folkntnu processes of coal mill in thermal power plant Coal is the mainly energy consumption, so it is the main problem to improve coal fired efficiency for thermal power plant Traditional ball mill has large power consumption in the process of production, and fineness of pulverized coal is not up to the standardThermal Power Plant Great Wall

Coal Mill Coal Fired Power Generation Shanghai

Vertical Coal Mill On the basis of retaining the advantages of RP grinders, the innovative HP mediumspeed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders Its grinding parts have a long service life and are easy to replace Ball Grinding Mill Dual inlet dual outlet steel ball mills have advantages of high rate of [6] P Niemczyk: “Improved coal grinding and fuel flow control in thermal power plants”, 18th IFAC World Congress, Milano, 28 August to 2 September 2011 [7] P Pradheepa, et al: “Modeling and Control of Coal Mill”, Tenth IFAC International Symposium on Dynamics and Control of Process Systems, Mumbai, 18 to 20 December 2013Coalmill optimisation in coalfired power stations Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating stationCoal handling plant in a thermal power generating

Flexibility in thermal power plants Agora Energiewende

3 Thermal power plant technology – Flexibility and comparison of generation technologies 33 31 Fundamentals of thermal power plant design and operation 34 32 Operational flexibility 42 33 Comparison of flexibility parameters in different generation technologies 46 4 Retrofits to increase flexibility of coalfired power plants – power plant to another However, current coalfired power generation is in competition with renewable energy and thus generation has shifted in many countries from baseload to load following mode necessitating flexibility in power plant operations As such, frequent cycling of coalfired power plants can cause thermal and pressure stressesOperating ratio and cost of coal power generation