Vertical Roller Mills

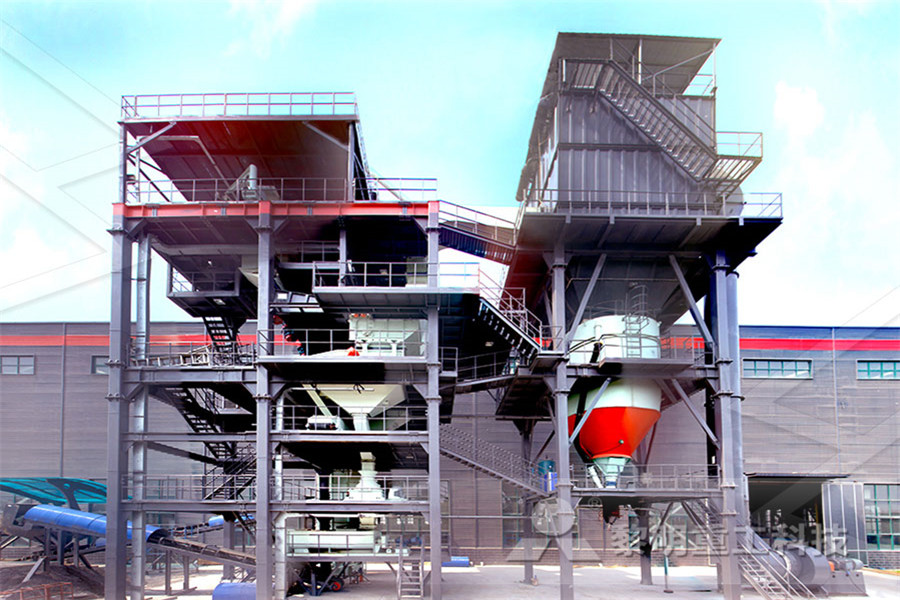

The advantages of the vertical roller mill include a high level of grinding efficiency combined with reduced energy consumption For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost Vertical Roller Mill for Cement, Clinker, Slag, etc From:未知 Date: 10:28 Application of vertical roller mill: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under Vertical Roller Mill for Cement, Clinker, Slag, etc vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller mill for raw Application p rocess materials

Productivity increase of the vertical roller mill for

Abstract: The specific power consumption, product quality and other performance of the "OK" and "CK" vertical roller mills for cement grinding are briefly stated Hence, the enhancement in increasing the productivity of the vertical roller mill at Chichibu Onoda Cement Corporation (COCC) is introduced 2 Reducing the power consumption of cement clinker preparation effectively According to the display of pulverized coal measured data, it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube millVertical Cement Mill Great Wall As the largest cement plant operator in India and one of the top 10 in the world, UltraTech Cement Ltd of Mumbai/India is looking ahead In connection with the realisation of 3 new clinker production lines, a letter of award for 9 vertical roller mills was granted to Gebr Pfeiffer and its Indian subsidiary Gebr Pfeiffer (India) Pvt LtdNine further vertical roller mills Mineral Processing

Cement grinding Vertical roller mills versus ball mills

grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalentCapacity of cement new production lines has steadily increased over the last years Reduction of investment costs is one of the most important driving factors for this trend Because of simple scalability and low energy consumption, the vertical roller mill is a key part for single mill cement lines The limits of material throughput of VRMs are, unlike other mill types, not defined by the Drive systems for vertical roller mills Semantic Scholar • Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants In this paper authors are covering the process diagnostic study of Ball mill for cement grinding 2PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Operational parameters affecting the vertical roller

Separation operation of verticalrollermill will be modelled by application of current models The model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treated Vertical roller mill is an advanced equipment concentrates on processing coal, cement, slag, nonmetallic mines and etcIt integrates crushing, drying, grinding, grading, and conveying in one unit It is a highyield and lowconsumption grinding mill developed by HongchengVertical Roller Milling Mineral Ores Production Line Vertical cement mill is the main milling machine in cement plant, with large capacity, energy consumption and its fineness is up to 00445mm In the complete cement production line, vertical roller mill is used in three processes Vertical roller mill for cement industryVertical cement mill,Vertical roller mill for cement

China Cement Vertical Mill Vertical Roller MillSlag

China Cement Vertical Mill Vertical Roller MillSlag Vertical Mill, Find details about China Vertical Mill, Cement Vertical Mill from Cement Vertical Mill Vertical Roller MillSlag Vertical Mill Qingdao Grandplan Technology Co, Ltd Vertical Roller Mill for Cement Raw Material SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/dVertical Roller Mill for Cement Raw Material SINOMALYThe advantages of the vertical roller mill include a high level of grinding efficiency combined with reduced energy consumption For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product Vertical Roller Mills

HLM Vertical Roller Mill newhcmilling

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process Two Types of vertical roller mill New type vertical roller mill is to solve the industrial grinding mill low yield , energy consumption higher technical difficulties, absorbing advanced technologies from Europe and combination of grinding milling machine many years design advanced manufacturing concept and the needs of the market, after years of painstaking the improved design of Vertical Roller Mill,Vertical Roller Mill Operation Keywords: Vertical Roller Mill, Grinding, Modeling, Simulation, Perfect Mixing Model 1 Introduction Energy consumption during the raw mix and cement grinding process in a cement plant is the most critical issue that has been debated till now as 90% of the energy consumed and lost as heat and noise energy The strategies against the risingApplication of perfect mixing model for simulation of

what is the difference between a vertical roller mill and

Vertical Roller Mill Raymond Mill Vertical mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under The mohs hardness, such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc A more appropriate term is vertical roller mill or VRM for short There are two different types of vertical mills: Vertical roller mills Such mills normally have integrated classifier This means plant design is more compact / simple in comparison to ball mill / classifier circuit On the other hand fineness is limited Agitated vertical millsVertimill VS Ball Mill Metallurgist Mineral Processing Vertical roller mill is an advanced equipment concentrates on processing coal, cement, slag, nonmetallic mines and etcIt integrates crushing, drying, grinding, grading, and conveying in one unit It is a highyield and lowconsumption grinding mill developed by HongchengVertical Roller Milling Mineral Ores Production Line

OZ Minerals, Loesche team up following West

The second stage of crushing and VRMs replaced a traditional SAG mill, ball mill and pebble crushing circuit OZ Minerals explained in the study: “Vertical roller mills are widely used in the grinding of cement plant feeds and products, slag, coal and other industrial minerals, with thousands currently in operation worldwide Vertical Roller Mill for Cement Raw Material SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/dVertical Roller Mill for Cement Raw Material SINOMALY Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cement and ceramics It is an energy efficient alternative for a ball millChina Vertical Cement Raw Mill Supplier, Clinker

Vertical Roller Mill Ball Mill Cement Mill Cement Kiln

2 天前 Vertical roller mill is mainly used for grinding raw meal, clinker, Ground Granulated Blast Furnace Slag, iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mine Working Principle: The material is fed through inlet pipe and falls to the Keywords: Vertical Roller Mill, Grinding, Modeling, Simulation, Perfect Mixing Model 1 Introduction Energy consumption during the raw mix and cement grinding process in a cement plant is the most critical issue that has been debated till now as 90% of the energy consumed and lost as heat and noise energy The strategies against the risingApplication of perfect mixing model for simulation of Two Types of vertical roller mill New type vertical roller mill is to solve the industrial grinding mill low yield , energy consumption higher technical difficulties, absorbing advanced technologies from Europe and combination of grinding milling machine many years design advanced manufacturing concept and the needs of the market, after years of painstaking the improved design of Vertical Roller Mill,Vertical Roller Mill Operation

Cement NETZSCH Grinding Dispersing

Cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together Cements used in construction are usually inorganic, often lime or calcium silicate based, and can be characterized as either hydraulic or nonhydraulic, depending on the ability of the cement to set in the presence of water EuroChem selected a LOESCHE mill type LM 242, with the proven vertical roller mill technology, for the production of ground phosphate As the pioneer in vertical roller mills technology LOESCHE has been successfully constructing and supplying phosphate mills worldwide since the 1960sThe LOESCHE mill in the new Mineral Processing A more appropriate term is vertical roller mill or VRM for short There are two different types of vertical mills: Vertical roller mills Such mills normally have integrated classifier This means plant design is more compact / simple in comparison to ball mill / classifier circuit On the other hand fineness is limited Agitated vertical millsVertimill VS Ball Mill Metallurgist Mineral