Gold Processing Plant Layouts scholmanloodgietersnl

Gold Processing Plant Layouts FOB Reference Price: Get Latest Price Dross Processing Equipment New Unique High Quality Designs SPRIT has recently expanded there dross pan casting line to include the manufacture of new dross compression units Dave Roth has worked on dross pressings since the late 1970s He is the key inventor in over 20 US and International patents in dross processing equipmentgold ore processing plant layout Gold processing 101 Mining Magazine If this ore also contains 1g/t Au (for GSR =1), and 90% recovery to concentrate is achieved, then 090g will be recovered and with a concentration ratio of 20 (5% to concentrate) this corresponds to 18g/t Au in concentrateGold Ore Processing Plant Layout hotelkottaram These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designs Prominer has established strategic relationships with Gold Processing,Extraction,Smelting Plant Design

Small Portable Gold Process Plant 911 Metallurgist

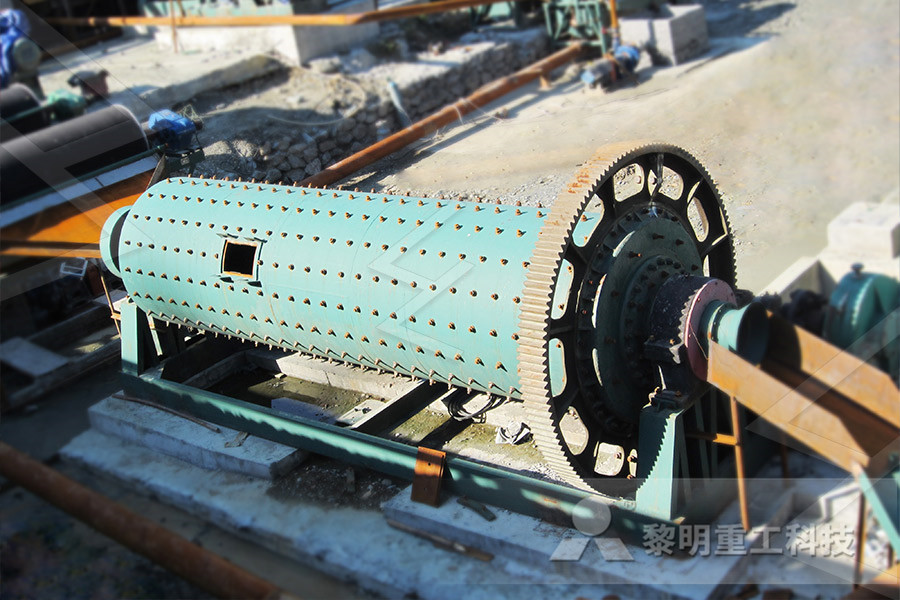

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing We can supply the whole line of gold washing plant, including: 1 gold trommel, vibrating screen,etc 2 jig machine 3 6S shaking table 4 excavator / bull loader 5 melting furnace 6 water pump diesel generator 7 electric control panel cables, etcAlluvial gold processing plant gold wash plant 40 TPD gold plant with crush, grind, gravity, and processing circuits plus lab 40 ton per day gold processing plant with mill and laboratory CRUSH: Jaw crusher: 7x10 in Hammermill: 15 HP 3x6 ft double deck screen Conveyors for feed and discharge GRIND: 4x4 ft Denver ball mill Used Gold Processing Plants for sale AllisChalmers

Gold Extraction, Gold Cyanide, Gold Manufacturing

Gold CIL Production Line [Introduction]: Gold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lowers the gold mining operation cost and increases gold recovery rate to 99%, which is the first choice of modern Metallurgical processing of metalliferous ores in general and gold ores in particular, consists essentially of three stages, often colloquially referred to as: Gold processing 101 Mining Magazine EXPLORER ® Alluvial Gold Processing Plants are configured with our special MultiStage Classification Trommels, which enables the plant to achieve up to three (3) sizes classification simultaneously as well as resolving the Heavy Clay content concern, Duplex Jig Concentrators and DOVE Centrifugal Gold Concentrators, which will ensure that the processing of the ore will capture Explorer Portable Plants Portable Wash Plants DOVE

Benefits of high frequency vibrating screen in gold

Benefits of high frequency vibrating screen in gold processing plant Vibrating screens are commonly positioned downstream of the cyclone overflow in order to clean the slurry and remove the trash prior to further gold ore treatmentThe thickened goldsilver concentrate from the Goldex processing plant is trucked to the LaRonde Complex, where it is fed to a cyanide leach circuit Goldbearing leachate is fed directly into the carboninpulp circuit to recover precious metals, which are smelted into doré bars ExplorationOperations Goldex Agnico Eagle Mines LimitedAll processing layouts were configured in and around the existing CIL Plant infrastructure to allow for potential future plant expansions The plant capital has allowed for all new equipment, except for the mill (see ASX release 2 Oct 2019: “Theta Agrees to Purchase Mill Operated by Glencore”)Theta (Open cut) Project – Theta Gold Mines

Examples of plant layout and design Jackson Productivity

Examples of plant layout and design Hi, I'm Jack Greene I sketched these layouts; most are real buildings which I have been in Some I built, some I laid out or modified Although none is perfect, the examples are full of sound principles, and represent actual, productive, operations (Sound principles allow a smooth product flow; provide During that time up to seven different gold bearing conglomerate horizons have been mined from surface down to a depth of 3,100 metres and total production for the combined Durban Roodepoort Deep and Rand Leases area was over 30 million ounces of gold at a grade in excess of 5 g/t (ASX: West Wits Mining Limited Prospectus 15/11/2007) Figure 1Witwatersrand Basin Project – WEST WITS MINING (for gold and silver operations), and dump leach materials (for copper leach operations) Leaching involving the use of cyanide is a kind of beneficiation process, usually used with gold, silver, and copper ores, that merits separate attention because of the serious environmental and public safety impacts With leaching, finely11 PHASES OF A MINING PROJECT ELAW

Create a plant layout Visio

After you assemble the building shell and wall structure, you can add electrical symbols and dimension lines Add electrical symbols From Electrical and Telecom, drag wall switches, outlets, and other wall fixtures onto wall shapesRelease the mouse button when a red square appears, indicating that the symbol is glued to the wall Wall fixtures rotate to align with the wall and glue to the wallAssisted LIO with the FEED of the process plant, completing initial process flowsheet designs and plant layouts including preliminary structural modelling, PDC’s, MEL’s, equipment and site specifications, and managing the initial assessment of water management structures associated with the designsCanencoBTech (Chem Eng), (Pr Eng) 10 years experiences in the Metallurgical Industry and Process Plant design commissioning Mineral Processing experience includes Crushing, Milling, Thickening, Leaching and Coal Processing Plant Process design engineering experience includes Gold, Chrome and CoalKEY TECHNICAL EXPERTS – UMS Group

Domain Surface Extraction

Operate a metalliferous gold mill processing plant This standard has expired and is no longer available 120 Credits: 12629: Unit: Treat all excess water from gold processing plant and recover all other run offs and seepages This standard has expired and is no longer available 80 Credits: 15663: UnitGranada Gold, Ontario, PFD, PID and 3d plant layouts DNI Metals, Vohitsara Graphite Project, General Arrangements Santa Rita Mining, Gold and SART Plant, PFD, PID and 3d plant layouts worked as a Lead Layout Designer on a project involving the Detailed Engineering of additional detoxification for gold ore processing plant in Tanzania Michael Jones Layout/Mechanical Designer Self The plant design has been based on a nominal capacity of 24 Mtpa of the Woodlark ore type through the processing plant, resulting in 967koz of Gold recovered The treatment plant design incorporates: Primary jaw crushing to produce a coarse crushed product; A SAB milling circuit comprising a SAG mill and a ball mill in closed circuit with Woodlark Island Gold Project Global Mineral

Agnico Eagle Mines Limited Operations Operations

The processing plant produces doré bars containing gold and silver, as well as zinc and copper concentrates that carry valuable gold and silver credits The plant has a daily capacity of 7,000 tonnes of ore and has been expanded four times since it opened in 1988 In addition, a dedicated 2,000tonnes/day carboninleach processing facility Mineral Processing Beatrix incorporates 1 Plant, which is part of the old Beatrix Mine and 2 Plant, which is located at 4 Shaft Beatrix 1 Plant is situated between 1 and 2 Shafts, to the west of the connecting road between the shaftsGOLD FIELDS Mineral Resource and Mineral Reserve Hambledon Mining plc is an AIMlisted gold mining and exploration company which is producing gold at and developing the Sekisovskoye gold deposit and owns the Ognevka processing plant, both of which are close to Oskemen (formerly UstKamenogorsk) in East KazakhstanHambledon Mining

BIOX Operations overendstudiocoza

The plant will initially only be fed with Wiluna material, but may in future be used as a central processing facility for concentrates produced at other mines The Sansu BIOX ® Plant The installation of the BIOX ® process for the treatment of the refractory gold concentrate at the Sansu Sulphide Treatment Plant at Obuasi in Ghana was a major Plant construction timeframe of nine months with concurrent 18 month underground mine development; Mineralised development material to be processed after 12 months from commencement of plant construction LOM recovered gold in concentrate production: 1,108,420 oz; Refining and Processing Charges: US$368/t concentrate or US$188/oz AuBlack Dragon Gold's Preliminary Economic Site Layout Factors The main factors that are considered when planning the layout of the plant are listed below 1 1 Economic considerations (construction and operating costs): Construction costs can be minimized by arranging process units and buildings that minimize pipes between equipment, the amount of structural steel work, etc However, this layout may conflict with the layout that Process location and layout decisions processdesign

Witwatersrand Basin Project – WEST WITS MINING

During that time up to seven different gold bearing conglomerate horizons have been mined from surface down to a depth of 3,100 metres and total production for the combined Durban Roodepoort Deep and Rand Leases area was over 30 million ounces of gold at a grade in excess of 5 g/t (ASX: West Wits Mining Limited Prospectus 15/11/2007) Figure 1Assisted LIO with the FEED of the process plant, completing initial process flowsheet designs and plant layouts including preliminary structural modelling, PDC’s, MEL’s, equipment and site specifications, and managing the initial assessment of water management structures associated with the designsCanenco After 3 or 4 weeks, given proper rainfall and a little watering, your “pot of gold” should be ready to use Then, simply place a handful of this composted material in a small hole 6 inches deep, for prestarted tomato plants several inches tall, where you plan to plant your vegetable gardenGreat layouts Blog