Iron Ore Processing Cost Patent warberehounennl

System And Method For Iron Ore Byproduct processing byproduct material from a direct reduction process of iron ore to this nonprovisional patent application claims priority under 35 usc 119 to the present invention provides costeffective, efficient methods and systems for ,continuous steel making process for iron ore,the invention discloses a continuous steel making process for iron ore Since its establishment in 1987, we has always focused on the RD and manufacturing of largescale equipment required for national infrastructure construction projects such as mines, buildings, and energyiron ore processing cost patent New dry iron ore processing technology developed May 26, 2016 Features Ben Creagh Sharon Masige The patent has been approved in the United States and is New dry iron ore processing technology developed

Dry processing of magnetic iron ores addressing

The iron ore industry has reached the end of an unprecedented period of expansion triggered by China's demand for iron ore Lower ore prices have led producers to focus on optimising mining operations while extracting the maximum tonnage from the infrastructure presently in place or from projects already underway A rising global surplus is expected to further force ore prices down and lead to Dry processing of magnetic iron ores – addressing cost and environmental issues W Skinner (1) and J R Kelly (2) AusIMM Iron Ore 2017 Conference, Perth, Australia, 2426 July 2017 Paper Number: 86 ABSTRACT The Iron ore industry has reached the end of an unprecedented period of expansion triggered by China‘s demand for iron oreDry processing of magnetic iron ores – addressing Different percentages of iron content reflect both the natural variation in iron ore grades found in mine deposits and the degree of processing (if any) employed to upgrade the ore for a certain use In general, higher purity ores help increase hot metal yields in the blast furnace, and also lower production cost Iron ore pricing explained Metal Bulletin

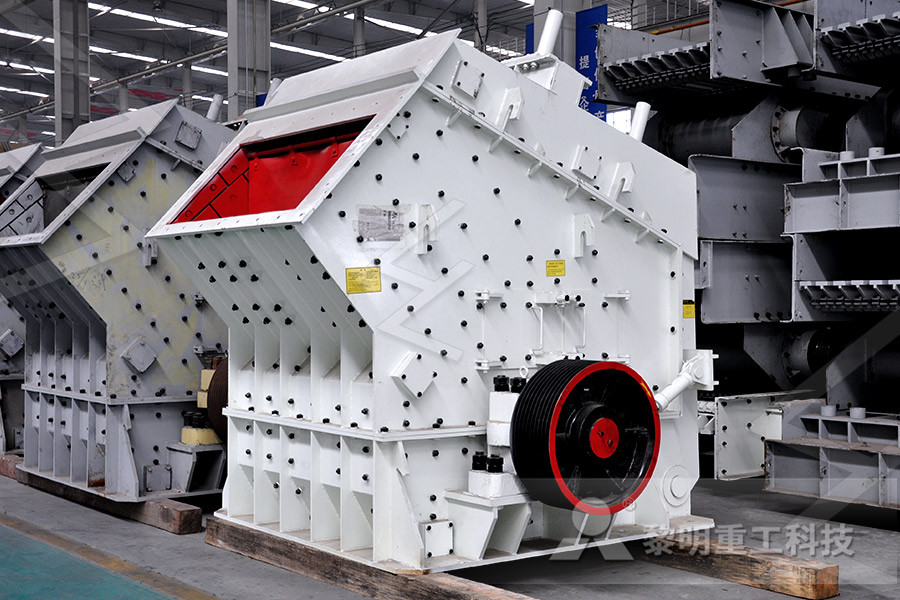

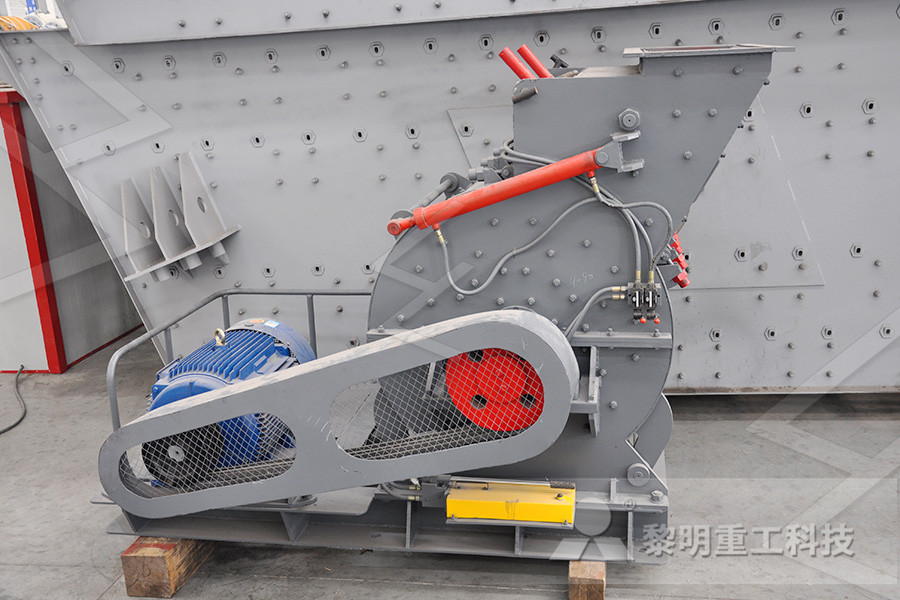

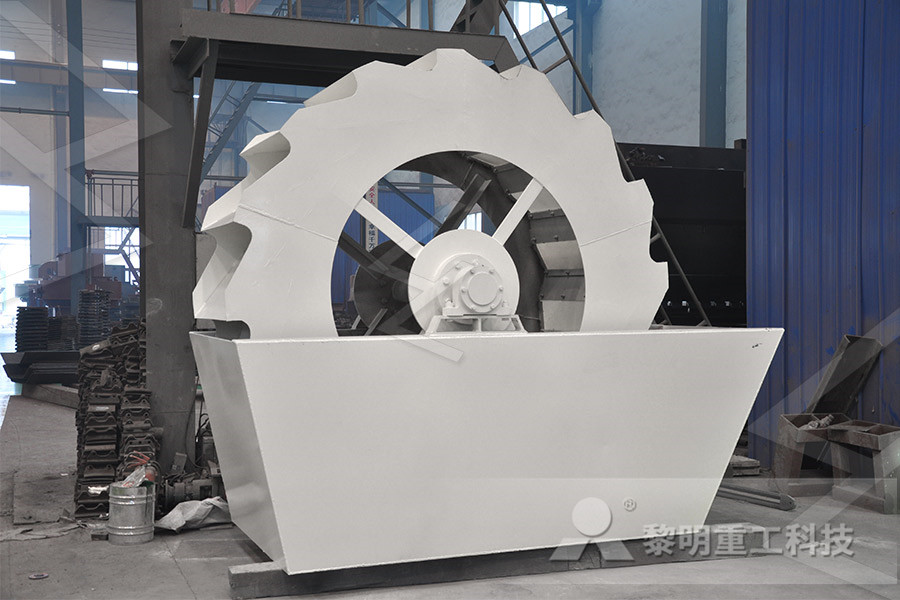

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron ore prices refer to Iron Ore Fine China Import 635 percent grade Spot Cost and Freight for the delivery at the Chinese port of Tianjin Is used to make steel for infrastructure and other construction projects The biggest producers of iron ore are China, Australia and Brazil Others include India, Russia, Ukraine and South AfricaIron Ore 20072021 Data 20222023 Forecast Price In 2003, one dmtu of iron ore cost 30 US dollars, and increased to a high of 168 US dollars per dmtu in 2011 The price saw dramatic drops in the past decade, from 13987 US dollars per dry Iron ore price monthly 20202021 Statista

New dry iron ore processing technology developed

New dry iron ore processing technology developed May 26, 2016 Features Ben Creagh Sharon Masige The patent has been approved in the United States and is 2 天前 Thirtysix years ago, Hu Guohua queued overnight outside China's patent office to apply for a patent The next day, April 1, 1985, China's Patent Law came into effect, and the office received more than 3,400 applications Eight months later, Hu got a patent certificate Newspapers splashed photos of First patent holder witnesses China's IP progress Cost of Production of Pig Iron Cost of production of pig steel from ore in the electric furnace is, of course, the main stumbling block to the success of such a process As yet not enough practical work has been done to give conclusive figuresPig Iron Manufacturing Process 911 Metallurgist

iron ore concentration Archives International Mining

Today, the company produces 60% of iron ore using natural moisture processing By 2024, from the production using wet processing (30%), 16% will have filtered and drystacked tailings, with only 14% continuing to use the conventional method with wet concentration and tailings disposal in dams or deactivated extraction sites With increasing demand for steel and depletion of highgrade iron ore deposits, more research efforts are being directed toward extending the life of existing ore reserves and developing technology to treat lowgrade iron ore resources Among all the reported technologies, biotechnologies in mineral processing — specifically bioleaching and microbially induced flotation — have emerged to Feasible bioprocessing technologies for lowgrade Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the Iron processing Britannica

The Use of Hydrogen in the Iron and Steel Industry

virgin iron added to dilute the tramp elements such as copper and zinc to improve final product quality • DRI – D irect R educed I ron is one of the iron products added to the scrap to increase purity • DRI is iron ore that has been reduced to iron with syngas without melting • DRI processes in US generally use natural gas to reduce Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace The resulting molten iron—also referred to as hot metal—still contains 445% carbon and other impurities that make it brittleSteps in the Modern Steelmaking Process The site operating cost for ore through to metal were reported to be $031 USD/lb of copper, one of the lowest cost operations in the world The Mt Gordon copper leach and process plant was shut down in 2004 due to change of ore type (no longer Esperanza chalcocite/pyrite) and corporate change of ownership to the Birla company from India 12Copper leaching from primary sulfides: Options for

Brazilian company patents innovative dry iron ore

Dry iron ore processing The mining activity produces lots of materials with no commercial value That is because the iron ore traded in the market must be composed of at least 58% of ore With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron oreFroth Flotation of Iron Ores article The Isua iron ore project is located in Greenland, approximately 150km northeast of Nuuk The project is owned by London Mining and includes the development of an open pit mine, ore processing plant, shipping and other necessary facilities and infrastructuresIsua Iron Ore Project Mining Technology Mining

Processes for phosphorus removal from iron ore a

2232 Flotation There are many citations in literature on the reduction of phosphorus in iron ore through anionic flotation, using a fatty acid as collector and sodium silicate as a depressant of iron oxides, when the mainphosphorusbearing mineral is apatite (Ranjbar, 2002 RANJBAR, M Dephosphorization of iranian iron oxide fines by flotation Erzmetall, v 55, n 11, p 612511 The MbalamNabeba iron ore project has been put on a fasttrack schedule, with production scheduled to begin in 2017 Environmental approval was obtained from Cameroon in July 2010 The definitive feasibility study for stage one and the prefeasibility study for stage two of the MbalamNabeba iron ore project was completed in April 2011Mbalam Iron Ore Project Mining Technology In an era of industrial expansion and technological advances, the Hulett OreUnloader helped Cleveland become one of the greatest steel manufacturing cities of the twentieth century The invention, designed by George Hulett, was vital to the production and processing of iron ore into steel In 1844, rich iron ore deposits were discovered in the Upper Peninsula of MichiganThe Huletts Cleveland Historical

Automation Rio Tinto

AutoHaul™ is the world’s first heavyhaul, longdistance autonomous rail operation, which transports iron ore to Rio Tinto's port facilities in the Pilbara region of Western Australia Our network includes about 200 locomotives on more than 1,700 kilometres of track in the Pilbara The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the pelletizing process Iron Ore Pelletizing Process: An Overview IntechOpenResults from the study to develop an upgrading method for producing highgrade iron from processing a goethite rich lowgrade iron ore are summarised in Fig 12 Following a microwaveassisted magnetising roast, a WLIMS operation in a loop involving rougher, cleaner scavenger unit operations on reduced samples could be successful in processing Beneficiation of lowgrade, goethiterich iron ore

Steel Production History of Western Civilization II

Steel is an alloy of iron and other elements, primarily carbon, that is widely used in construction and other applications because of its high tensile strength and low cost Steel’s base metal is iron, which is able to take on two crystalline forms, bodycentered cubic (BCC) and