nickel ore and concentrate difference

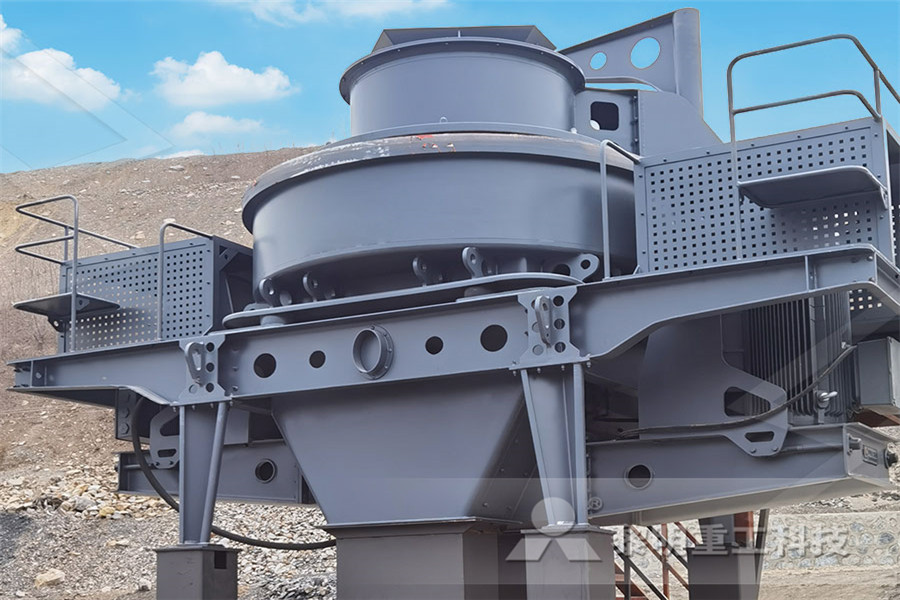

nickel ore and concentrate difference nickel ore and concentrate difference GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction Passing the can test on nickel ore cargoes S The London PI Club that the difference in the characteristics between nickel ore and a metal concentrate means that great care is required when testing nickel ore to JUNE 2007 Read morenickel ore and concentrate difference Nickel ore and concentrate difference the concentrate from the first flotation circuit is treated in a second flotation circuit to produce a nickel–cobaltrich concentrate and a copperrich concentrateThe second flotation circuit is a slightly different configuration of flotation equipment than that shown in figure 2Flotation Concentrate For Nickel Ore logopedia

concentrate nickel processing

nickel ore concentrate machineconcentratorthickner 31/05/2018 nickel ore concentrate machineconcentratorthickner offers 2435 copper ore concentrate products About 10% of these are copper ore, 1% are separation equipment A wide variety of copper ore concentrate options are available to you, such as is concentrate, nonconcentrate More the nickel grade in the concentrate There is a distinct difference in silicate mineralogy between types of host rock, which have their own problems with respect to rejection of gangue by SotationTalc and other naturally hydrophobicmagnesiabearing minerals have a tendency to Soat with sulRdes, resulting in a concentrate exceptionally highNICKEL AND COBALT ORES: FLOTATION 911 Metallurgist In Nickel Silica the Ni = 1220% the Fe = 1529 % the SiO2 = 3050 % S and P levels are the same for both type, less than 0,01 % and of course in all our ores, the Moisture is very Low when compared to most other Ore Suppliers These specs above are to show the main difference between some of the Nickel Ore FerroNickel Ores Accrue Group Holdings

General Introduction to Nickel

1Nickel Production Nickel Ore Production 4% China nickel ore resource is limited, and the international dependence of nickel ore resource is high In 2013 China nickel ore production (as converted to nickel metal quantity) was roughly 92 KTA, where the share of Gansu province was 80%, and the share of Gansu, Jilin and Xinjiang exceeded 90% Iron ore fines and nickel ore By Dr Martin Jonas, Brookes Bell, Liverpool (see Figure 1) This suddenly reduces the friction between particles, and thus the shear strength of the cargo The effect of this process is a transition from a solid state to a viscous fluid state in which all or part of the cargo can flatten out to form a fluid surfaceLiquefaction of GARDSeparation Of Mineral From Crushed Ore Nickel mineral separation for nickel Magnetic PERMANENT 4 2 1 Magnetic Separation of Free Metals As discussed in the section on asteroid resources asteroids are rich in free nickeliron metal granules mineral separation for nickel,Froth flotation ore crusher priceFroth flotation is a process for selectively separating Minerals Separation Froth How Nickel Is Separated From Mineral

Nickel Sulfide Versus Laterite : The Hard Sustainability

difference between production and resources is due mainly to the difficulty associated with processing laterite compared to sulfide ores – leading to a historical preference for sulfide ores To meet future demand for nickel, however, there is an increasing proportion of nickel nickel ore and concentrate difference Home / News Article / nickel ore and concentrate difference 2019/03/24 Author:SKM Chat Online Viscosity of raw material means a lot to the production capacity of Raymond mill The higher the viscosity of raw material, the easier raw material will adhere, and the production capacity will decreasenickel ore and concentrate difference Concentrate Nickel Processing, Stone crushers China Nickel ore processing plant Mining , crushing, grinding Machinery offers complete set of nickel ore processing equipment like Concentrate Nickel Processing

concentrate nickel processing

Extractive Metallurgy of Nickel, Cobalt and Platinum Group The four main steps of the process are dewatering—the removal of mechanically entrained water from the concentrate, calcination—the removal of chemically bonded water from the dried ore, reduction—the removal of oxygen from the nickel and iron oxide in the calcine, and refining—the removal of impurities, such as the nickel grade in the concentrate There is a distinct difference in silicate mineralogy between types of host rock, which have their own problems with respect to rejection of gangue by SotationTalc and other naturally hydrophobicmagnesiabearing minerals have a tendency to Soat with sulRdes, resulting in a concentrate exceptionally highNICKEL AND COBALT ORES: FLOTATION 911 Metallurgist2 天前 Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel processing Extraction and refining Britannica

Sulphide Nickel Production and Supply: Market Implications

of Ore in China 17 Change in Chinese Nickel Ore Port Stocks and Implied Consumer Stock Change (Mt)15105 0 5 10 15 20 2013 2014 YTD August 2015 Port Stocks Consumer Stocks Source: Ferroalloynet, GTIS, Macquarie, RNC Analysis Implied Consumer Stock Change is difference between ore consumption, net imports, and change in port stocks However, producers then make a concentrate from thesulphide ore, upgrading the materialfrom anywhere from 033% nickel to 1015+% nickel for relatively littleadditional cost This process is relatively uncomplicated and inexpensive; itneeds to be smelted, refined, and then the process is complete Nickel Laterite Cheap to mine, expensive to Nickel Class 1 Class 2 – Why Does It Matter For A nickelcopper sulphide concentrate was treated in a pilot plant at Warren Spring Laboratory during 1961, by a hydrometallurgical roastleachsolvent extraction process devised to cleanly separate the metal values, and produce acid sulphate liquors containing the metalsCopperNickel Ore Processing 911metallurgist

London Metal Exchange: LME Nickel

LME Nickel Contract specifications Every metal traded on the LME must conform to strict specifications regarding quality, lot size and shape Each LME tradeable contract is likewise governed by rules covering (but not limited to) prompt dates, settlement terms, traded and cleared currencies and minimum tick size The nickelcopper sulphide ore used in this study was supplied by Trojan Nickel Mine located in Bindura, Zimbabwe From the Xray diffraction analysis, the main phases present in the ore were pentlandite (494%), pyrrhotite (412%) and quartz (46%), Fig1 The ore which was supplied in lumpy form was subjected to crushing and grindingFlotation of NickelCopper Sulphide Ore: Optimisation of nickel ore and concentrate difference Home / News Article / nickel ore and concentrate difference 2019/03/24 Author:SKM Chat Online Viscosity of raw material means a lot to the production capacity of Raymond mill The higher the viscosity of raw material, the easier raw material will adhere, and the production capacity will decreasenickel ore and concentrate difference

Nickel processing Extraction and refining Britannica

2 天前 Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Ore is worth processing for the metals content, dirt is not, even though that dirt will contain some uranium, some gold, some silver, nickel and all of the restThe Astonishing Nickel Eating Plant That Could Re: Nickel Oxide Vs Nickel Sulphide Nickel sulphides are where the majority of the world's nickel has come from until now The technology is wellunderstood and tried and tested The sulphide ore is crushed and flotation cells are used to form a nickel sulphide concentrate The concentrate is then roasted in a smelter to produce nickel metalNickel Oxide vs Nickel Sulphide Aussie Stock Forums

CopperNickel Ore Processing 911metallurgist

A nickelcopper sulphide concentrate was treated in a pilot plant at Warren Spring Laboratory during 1961, by a hydrometallurgical roastleachsolvent extraction process devised to cleanly separate the metal values, and produce acid sulphate liquors containing the metals Some factories sorted nickel concentrate (10% nickel), copper concentrate and magnetic iron sulfur concentrate from mixed concentrate Nickel concentrate or mixed concentrate usually use pyrometallurgy, produce the intermediate products nickel matte, make copper and nickel enriched in sulfide form, and then refining and purifying to get nickelNickel smelting Articles Factory The ore is mixed with calcium oxide and silica, producing a slag This makes it possible to separate silver, a mixture of materials rich in copper, nickel and cobalt and a scorifiable residue This mixture rich in copper, nickel and cobalt is what is technically called “speiss” Getting from this mixture to the pure metal is a complex processNickel / cobalt mining extraction procedures

London Metal Exchange: LME Nickel

LME Nickel Contract specifications Every metal traded on the LME must conform to strict specifications regarding quality, lot size and shape Each LME tradeable contract is likewise governed by rules covering (but not limited to) prompt dates, settlement terms, traded and cleared currencies and minimum tick sizeNickel Facts – Chemistry – Properties: The melting point of nickel is 1453°C, boiling point is 2732°C, specific gravity is (25°C), with a valence of 0, 1, 2, or 3Nickel is a silvery white »More detailedwhat is the specific gravity of nickel « MiningThe useful minerals of Jinchuan highgrade copper and nickel suphfide ores were mainly nickel and copper, whose grade were respectively 142% and 101% The content of MgO and SiO2, main gangue components, reached 5789% The key to improve the separation indexes of flotation concentrate was to inhibit the gangue minerals effectively, therefore, the effects of different kinds of regulators on Flotation Behavior of Jinchuan High Grade Copper