Single Tooth Roller Crusher ZY mining

11 行 The singletooth roller crusher adopts the alloy steel tooth plate and the surface is covered with The single toothed roll crusher that we manufacture is actually a rotary roller which consists of a large tooth and also a crushing plate which is adjustable according to the need and requirement The material that is fed into the single roll crusher is smashed first and then pressed from inside of the single tooth roll Single Roll Crusher Manufacturers and Exporters IndiaSingletooth roll crusher, Model is PGC1832, Singletooth roll crusher Manufacturer/Supplier/Factory From Luoyang China Luoyang Zhongyuan Miningsingle roll crusher with double teeth

Analysis Calculation on SingleTooth Roll Mobile Crusher

Using the second crushing theory and combining with the singletooth rolling mobile crusher mechanism analysis, a singletooth rolling mobile crusher mechanical model was established Through analysis of force on the tooth roller, deduced calculation formulas of the teeth roll tangential force, the tangential force by an example calculation was Single Roll Crushers, sometimes called lump breakers, can also be used for breaking frozen or agglomerated materials Williams Roll Crushers are used in a variety of industries such as, mining recycling, and power industries Interested in learning more about the Williams Roll Crushers for your specific industry and application?Roll Crusher Manufacturer Design Williams Crushersingle roll crusher with double teeth For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklysingle roll crusher with double teeth

Roll Crushers McLanahan

Single Roll Crushers Single Roll Crushers are typically used as primary crushers that provide a crushing ratio of up to 6:1 They crush materials such as ROM coal, mine refuse, shale, slate, gypsum, bauxite, salt, soft shale, etc, while producing As the main working part, the two cylindrical rollers rotate oppositely to achieve the purpose of crushing Due to its peculiar tooth crushing structure, it is also called Teeth Roll Crusher The Classification The commonly seen roller crusher falls into three types: single roll crusher, double roll crusher and four roll crusherRoll Crusher,Roller Crusher,Double Roll Crusher,Teeth Roll Double Toothed Roll Crusher Applied material: coal, pebble, perlite, limestone, dolomite, etc Its outstanding features: high crushing capacity, hadraulic pressure used to adjust the distance between the rollers, and the centralization Reliable Toothed Roll Crusher Fote Machinery(FTM)

Ecoman Stainless Steel Single Toothed Roll Crusher,

Ecoman Offering Ecoman Stainless Steel Single Toothed Roll Crusher in Vadodara, Gujarat Get best price and read about company Get contact details and address ID: single toothrollcrusher Apr 01, 2020 single roll crusher manufacturers and exporters india ecoman indiathe single toothed roll crusher that we manufacture is actually a rotary roller which consists of a large tooth and also a crushing plate which is adjustable accordingroll crusher manufacturer design williams crushersingle roll crushers, sometimes called lump breakers, can also be single tooth crusher InduzinCan be executed in smooth roll, Small tooth, Big tooth, Single piece roll or roll made up of rings on hexagonal rotors etc etc Further application can be for pet coke, coal, Iron ore, Clinker etc We can offer with either mechanincal or Hydraulic SpringsSizes of upto 1200Ø and widths upto 2000mm suppliedRoll Crusher Machine Single Roll Crusher

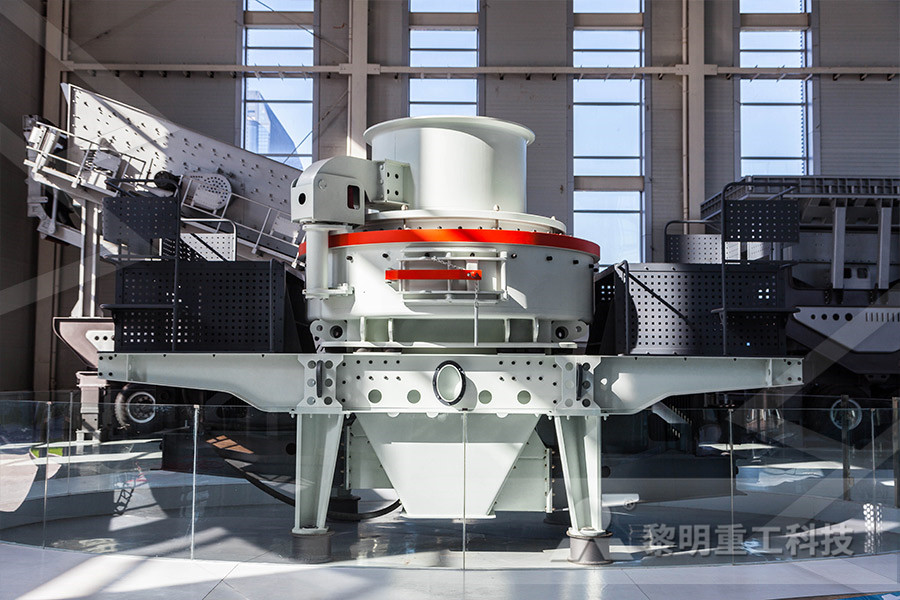

Singleroll CrusherProduct Ande Metallurgical

Singleroll crusher is applied for crushing of fragile and low/mediumhardness material, such as sinter, slag, shale, limestone and etc Single roll crusher integrates jaw crusher and roll crusher together, thus has characteristics of the two types of crushers Mode of operation As the main working part, the two cylindrical rollers rotate oppositely to achieve the purpose of crushing Due to its peculiar tooth crushing structure, it is also called Teeth Roll Crusher The Classification The commonly seen roller crusher falls into three types: single roll crusher, double roll crusher and four roll crusherRoll Crusher,Roller Crusher,Double Roll Crusher,Teeth Single Roll Crushers McLanahan The Single Roll Crusher, with its 6:1 ratio of reduction, is ideal for reducing large feed lumps to a medium product size while producing a considerably lower percentage of fines The minimum product sizing of a Single Roll Crusher is generally limited to 23” The crushing is carried out between the full width of the extralong curved crushing plate and the low single roll crushing equipment with double teeth

Single Roll Crusher With Double Teeth

Coal Single Roll Crusher Mechanism Coal Single Roll Crusher Mechanism Analysis calculation on single tooth roll mobile crusher using the second crushing theory and combining with the singletooth rolling mobile crusher mechanism analysis a singletooth rolling mobile crusher mechanical model was established through analysis of force on the tooth roller deduced calculation formulas of Double tooth roll crusher for sale in India double toothed roll crusher in India The Indian customer’s coal mine adopts the singlebucket truck with semicontinuous mining process, and the raw coal has large grain size, gangue with great hardness In the original production line, he firstly crushed the material to less than 300mm, then Reliable Toothed Roll Crusher Fote Machinery(FTM)Single Roll Crusher Vs Two Roll buddymobilde Single Roll Crusher Vs Two Roll Single roll crusher with double gear stone crusher machine single roll crusher stone crusher used for ore jan 08, gear teeth are designed with a wide face and large profile for maximum strength and power transmission with the exception of the cobra single single roll crusher vs two roll emiratesrelocation

What is a roll crusher? – Mineral processing equipment

Roll crusher machine A Roll crusher is a size reduction machine consists of two rolls space from each other by a gap opening The rolls rotate towards each other The ore enters the feed opening, being rolled and ground between the surfaces of the rolls faces, then discharged out of the crusher under gravity and rotating actionsBevcon Single Roll Crusher is typically primary crusher The crushing technique involves the operations like Impact, shear and compression The material entered in the crushing chamber is struck hard against a rotor consisting of series of teeth mounted on a rotor Material is crushed between teeth and a breaker plate consisting of hard liners Providing a crushing ratio of up to 6:1, Bevcon Single Roll Crusher Bevcon Wayors Bulk Made SimpleThe single toothed roll crusher that we manufacture is actually a rotary roller which consists of a large tooth and also a crushing plate which is adjustable according to the need and requirement The material that is fed into the single roll crusher is smashed first and then pressed from inside of the single tooth roll breaker followed by Single Roll Crushers Manufacturer Supplier in

Ecoman Stainless Steel Single Toothed Roll Crusher,

Ecoman Offering Ecoman Stainless Steel Single Toothed Roll Crusher in Vadodara, Gujarat Get best price and read about company Get contact details and address ID: Coal Single Roll Crusher Mechanism Coal Single Roll Crusher Mechanism Analysis calculation on single tooth roll mobile crusher using the second crushing theory and combining with the singletooth rolling mobile crusher mechanism analysis a singletooth rolling mobile crusher mechanical model was established through analysis of force on the tooth roller deduced calculation formulas of Single Roll Crusher With Double Teeth Single Roll Crushers McLanahan The Single Roll Crusher, with its 6:1 ratio of reduction, is ideal for reducing large feed lumps to a medium product size while producing a considerably lower percentage of fines The minimum product sizing of a Single Roll Crusher is generally limited to 23” The crushing is carried out between the full width of the extralong curved crushing plate and the low single roll crushing equipment with double teeth

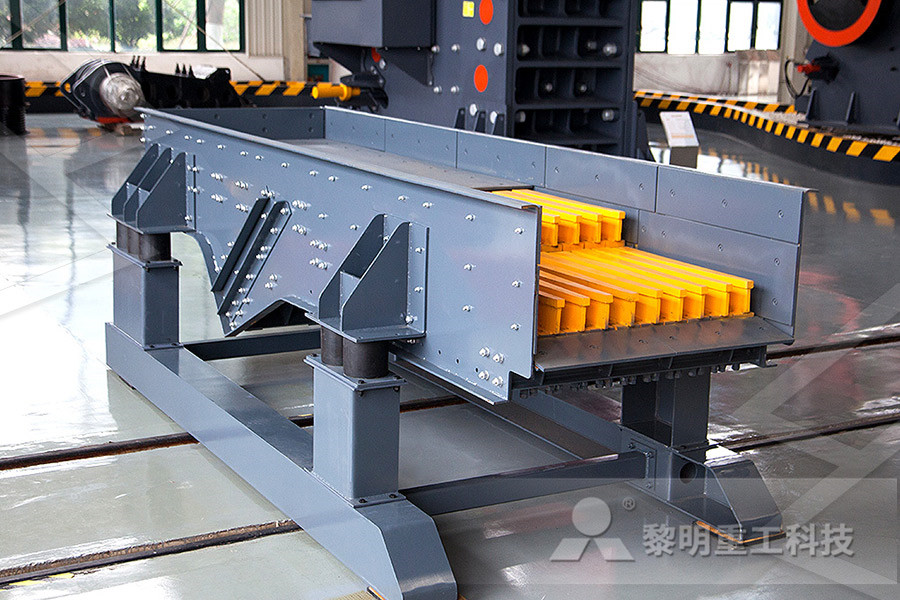

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth

As the main working part, the two cylindrical rollers rotate oppositely to achieve the purpose of crushing Due to its peculiar tooth crushing structure, it is also called Teeth Roll Crusher The Classification The commonly seen roller crusher falls into three types: single roll crusher, double roll crusher and four roll crusher Stone roll crusher can be divided into singleroll, doubleroll and multiroll several types according to the number of rollers According to the shape of the roll surface, have two kinds, smooth roll and tooth roll The former is suitable for medium and fine crushing of medium hardness ores While the latter is suitable for coarse and medium Roller Crusher Single/Double Roll Crushers JSXC MineSingle Roll Crusher Vs Two Roll buddymobilde Single Roll Crusher Vs Two Roll Single roll crusher with double gear stone crusher machine single roll crusher stone crusher used for ore jan 08, gear teeth are designed with a wide face and large profile for maximum strength and power transmission with the exception of the cobra single single roll crusher vs two roll emiratesrelocation

Roll Crusher Manufacturer Design Williams Crusher

Use an IndustryLeading Roll Crusher on Your Next Job The Williams Patent Crusher Roll Crushers are designed to crush friable materials such as coal, limestone, clay, mineral, and diatomaceous earth for the mining, recycling, and power industries Williams is an industryleading roll crusher manufacturer and designer for highquality roll crushers with desirable benefits such as high Roll crusher machine A Roll crusher is a size reduction machine consists of two rolls space from each other by a gap opening The rolls rotate towards each other The ore enters the feed opening, being rolled and ground between the surfaces of the rolls faces, then discharged out of the crusher under gravity and rotating actionsWhat is a roll crusher? – Mineral processing equipment