Closed Circuit Grinding Ball Mill divinechannel

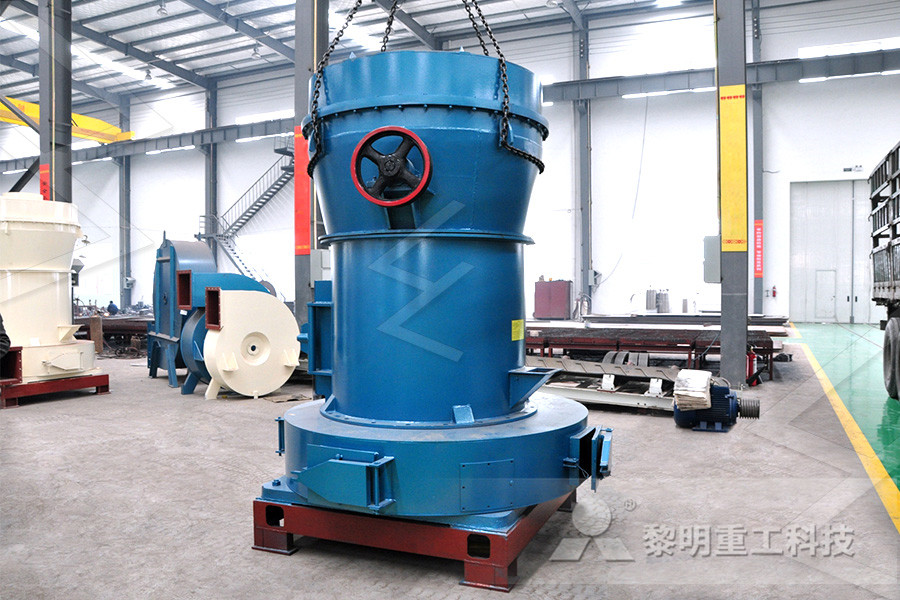

Closed Circuit Grinding Ball Mill Jun 11 2020 1 Introduction Over the years ball mill circuits closed with cyclones have become an industry standard and since the early days it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding ie its capacity to produce the desired final productOver the years, ball mill circuits closed with cyclones have become an industry standard, and since the early days, it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding (ie its capacity to produce the desired final product)closed circuit ball mill grinding vietlongch 1 Introduction Over the years, ball mill circuits closed with cyclones have become an industry standard, and since the early days, it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding (ie its capacity to produce the desired final product)Closed circuit ball mill – Basics revisited ScienceDirect

closed circuit grinding ball mill

closed circuit grinding ball mill The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier the flow sheet is shown in Fig 25 and the actual layout in Fig 9 This singlestage circuit is chiefly employed for coarse grinding when a Closed Circuit Grinding The object of these tests was to determine the crushing efficiency of the ballmill when crushing in closed circuit with a classifier The conditions were as follows: Feed rate, variable from 4 to 15 T per hr Ballmill power, 108 kw Ball Ball Mill Grinding Theory Crushing Motion/Action In their plant grinding is carried out in a Hardinge Ball Mill in closed circuit with a Dorr Classifier, and a “ SubA” Cell is employed as the flotation unit between the two, the pulp being maintained at a density of 65% solids Under normal operating conditions 6070% of the copper and 40% of the nickel are recovered in the grinding circuitFlash Flotation with Closed Circuit Grinding

Grinding Circuit an overview ScienceDirect Topics

The circuit comprises a SAG mill, 12 m diameter by 61 m length (belly inside liners, the effective grinding volume), two pebble crushers, and two ball mills in parallel closed with cyclones The SAG mill is fitted with a 20 MW gearless drive motor with bidirectional rotational capacityTherefore, Equations 2 and 3 should be combined with Equation 4 when assessing the relative capacity of a grinding circuit Closed HPGR circuits As demonstrated, circulating load and classification efficiency have a significant impact on the efficiency and capacity of closed ball mill circuits(PDF) Effect of circulating load and classification Grinding media is grinding feed plus 412% ball charge (ball dia100 125 mm) High capacity (short retention time) Less sensitive to feed composition (critical size material) SemiAutogenous Mill Note the size of the mill: Why does the diameter need to be so big? [image: (13562)] SAG Mill Circuit AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

Closed Circuit Grinding Ball Mill

Closed Circuit Grinding Ball Mill Jun 11 2020 1 Introduction Over the years ball mill circuits closed with cyclones have become an industry standard and since the early days it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding ie its capacity to produce the desired final productOver the years, ball mill circuits closed with cyclones have become an industry standard, and since the early days, it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding (ie its capacity to produce the desired final product)closed circuit ball mill grinding vietlongchBall mill Wikipedia Advantages of the ball mill Ball milling boasts several advantages over other systems: the cost of installation and grinding medium is low; the capacity and fineness can be adjusted by adjusting the diameter of the ball; it is suitable for both batch and continuous operation; it is suitable for open and closedcircuit grinding; it is applicable for materials of all capacity ball grinding Prominer (Shanghai) Mining

A survey on troubleshooting of closedcircuit grinding

ABSTRACT An industrial ball mill operating in closedcircuit with hydrocyclones was studied by five sampling surveys The aim of the present study was to optimise operating parameters (ie charge volume, makeup ball size regime, slurry mean residence time, number of hydrocyclones in operation and hydrocyclone’s feed solids content (Sf)) with respect to increasing throughout from 225 to 300 Therefore, Equations 2 and 3 should be combined with Equation 4 when assessing the relative capacity of a grinding circuit Closed HPGR circuits As demonstrated, circulating load and classification efficiency have a significant impact on the efficiency and capacity of closed ball mill circuits(PDF) Effect of circulating load and classification Closed Circuit Grinding VS Open Circuit Grinding 911 Metallurgist Mar 17, 2017 The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is ball mills closed

How to Choose Opencircuit Grinding or Closed

01 The specifics of two grinding ways Openingcircuit grinding is that, in the grinding operation, the material is fed into the mill and discharged after a grinding, directly into the next mill or the next process The advantages of openingcircuit grinding are simple processing flow and lower investment cost While the disadvantages are lower production rate and large energy consumptionGrinding media is grinding feed plus 412% ball charge (ball dia100 125 mm) High capacity (short retention time) Less sensitive to feed composition (critical size material) SemiAutogenous Mill Note the size of the mill: Why does the diameter need to be so big? [image: (13562)] SAG Mill Circuit AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Using these results, ways to increase production capacity of closedcircuit grinding were investigated The lower the filling ratio of powder in the ball charge under the condition of constant passing rate of powder through a mill, the more the production capacity increases both the raw mix and the clinker grindingEffect of Milling Condition of a Tumbling Ball Mill on

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

For primary grinding, the ratio could vary between 1:1and 18:1 For fine regrinding in open circuit, the ratio ranges from 13:1 to 15:1 Some ball mills are separated in to compartments by grates The grates hold back particles above a certain size for additional grinding The compartments could contain different ball The closedcircuit grinding system, all ground materials are led into a separator and classified into refined powder (products) and coarse powder (return powder) The coarse powder is returned to the ball mill and ground again with newlyfed raw materials Following benefits can be realized with this technology: Grinding capacity increases;Closed circuit systems for ball mills Industrial Over the years, ball mill circuits closed with cyclones have become an industry standard, and since the early days, it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding (ie its capacity to produce the desired final product)closed circuit ball mill grinding vietlongch

A survey on troubleshooting of closedcircuit grinding

ABSTRACT An industrial ball mill operating in closedcircuit with hydrocyclones was studied by five sampling surveys The aim of the present study was to optimise operating parameters (ie charge volume, makeup ball size regime, slurry mean residence time, number of hydrocyclones in operation and hydrocyclone’s feed solids content (Sf)) with respect to increasing throughout from 225 to 300 Closed Circuit Grinding VS Open Circuit Grinding 911 Metallurgist Mar 17, 2017 The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is ball mills closed The benefits of screen sizing in closed circuit grinding are illustrated by case histories from a wide spectrum of mineral industriesINTRODUCTIONHigh capacity, reliable wet screening equipment is increasingly in demand by the mining and allied industries for separations finer than 1/7 5mm (I/ mesh)ClosedCircuit Grinding with Vibrating Screens

Modern Tph Closed Circuit Ball Mill Mill

Both Open Circuit Grinding And Closed Circuit Modern tph closed circuit ball mill Jan 02 2018 modern cement grinding process with close circut Circuit Grinding Close gatewaypreschool modern cement grinding process with close 4 process b is a closed circuit grinding process combining an air separator and a Know More Get Price 110 tph capacity 01 The specifics of two grinding ways Openingcircuit grinding is that, in the grinding operation, the material is fed into the mill and discharged after a grinding, directly into the next mill or the next process The advantages of openingcircuit grinding are simple processing flow and lower investment cost While the disadvantages are lower production rate and large energy consumptionHow to Choose Opencircuit Grinding or Closed Using these results, ways to increase production capacity of closedcircuit grinding were investigated The lower the filling ratio of powder in the ball charge under the condition of constant passing rate of powder through a mill, the more the production capacity increases both the raw mix and the clinker grindingEffect of Milling Condition of a Tumbling Ball Mill on

Optimizing Performance of SABC Comminution Circuit of

overflow ball mill and closed stockpile (maximum storage capacity at 120,000 t, effective storage capacity at 39,000 t) Figure 1 Wushan Phase I SABC circuit layout and equipment specifications After three years of operation, continued analysis of the circuit products showed there were considerable performance issues present Almost all ball mills use a form of closed circuit grinding that returns material that is too coarse back to the ball mill inlet while material fine enough to meet product requirements is collected The separator determines which particles will be returned and which particles are sufficiently fineGrinding balls are utilized in the ball mills jennifer0972 博