wet magnetic separation process salzgrottesteinch

Magnetic separation process is a dry and wet magnetic separation process method for magnetite The magnetic separation process is mainly a threelevel magnetic separation process for ore powder After wet material magnetic separation, the magnetic field strength selected for magnetic separation is 400 ~ 1200 GS, The magnetic drum rotation speed is 60 to 320 revolutions per minute In essence, any magnetic separator operates on the basis of imparting a preferential magnetic force on particles of higher magnetic susceptibility which are to be separated from particles of lower magnetic susceptibility A certain amount of Wet Magnetic SeparationMagnetic separation is the process of separating components of mixtures by using magnets to attract magnetic materials The process that is used for magnetic separation detaches nonmagnetic material with those that are magneticmagnetic wet magnetic separation process

Environmentallyfriendly oxygenfree roasting/wet

Wet magnetic separation A magnetic stirrer (HJ3, Shenglan Co) was used to separate products from the mixture after roasting The structure of magnetic stirrer was given in Fig 3 During the separation, the solution temperature is 20 °C, the solid/liquid ratio was 1:200, the stirring speed was 1000 rpm, and the stirring time was 48 hMagnetic Separation Process Machinery The Description and Function of Magnetic Separation Process: Magnetic selected process is a wet and dry joint dressing process for separation of magnetite, mainly Magnetite Separation Production Line Mineral Weak magnetic iron ore separation processdrying magnetite in wet separation processThe core factor of magnetic separation process——Magnetic Susceptibility Aiming at the characteristics of magnetic strength, Xinhai introduced different magnetic separation processes to process minerals with different magnetic strength Weak magnetic field magnetic separation process is mainly used to recover strong magnetic mineralsMagnetic Separation, Magnetic Separation Process,

A discussion of magnetic separation techniques for

requirements for obvious cost implications Employing wet magnetic separation early in a process can greatly benefit an operation if a lowgrade final tailing, or a clean marketable product, can be produced, since it alleviates both drying and dry storage costs While WHIMS use can be advantageous, a Lv, X, Xin, Y, Lv, X et al HighTitanium Slag Preparation Process by Carbothermic Reduction of Ilmenite and WetMagnetic Separation Metall Mater Trans B 52, 351–362 (2021) /101007/s1166302002027z Download citation Received: 03 August 2020 Accepted: 29 October 2020 Published: 19 November 2020 Issue Date: February 2021HighTitanium Slag Preparation Process by A wet drum separator in action An example of a concentrator operating on a dry feed is a rotating disc separator The material is fed continuously in a thin layer beneath a rotating magnetic disc which picks up the magnetic material in the zone of high magnetic intensityMagnetic Separator an overview ScienceDirect Topics

wet magnetic separation process salzgrottesteinch

The magnetic separation process is mainly a threelevel magnetic separation process for ore powder After wet material magnetic separation, the magnetic field strength selected for magnetic separation is 400 ~ 1200 GS, The magnetic drum rotation speed is 60 to 320 revolutions per minute Chat Online In essence, any magnetic separator operates on the basis of imparting a preferential magnetic force on particles of higher magnetic susceptibility which are to be separated from particles of lower magnetic susceptibility A certain amount of directional deviation to the particles takes place thus allowing for collecting each category of particles separately Under fixed feeding conditions of Wet Magnetic Separation Additionally, a wet process often produces a better separation for very fine materials In this educational video, Professor Neil Rowson describes and demonstrates the laboratoryscale Wet High Intensity Magnetic Separator Wet High Intensity Magnetic Separation Bunting

Chemical conditioning for wet magnetic separation of

The best Separation Efficiency, considering the major economic elements, is up to 83% in a single roughing step under the low intensity wet magnetic separation With evolution in PCB dust complex material streams for beneficiation, chemical conditioning has appeared as a vital factor to make wet magnetic separation effectiveMagnetic Separation Process Machinery The Description and Function of Magnetic Separation Process: Magnetic selected process is a wet and dry joint dressing process for separation of magnetite, mainly Magnetite Separation Production Line Mineral Weak magnetic iron ore separation processdrying magnetite in wet separation processThe insights gained, and the methods developed, have generated new possibilities to control, optimise, and develop the wet LIMS processKeywords: Wet lowintensity magnetic separation, magnetite beneficiation, inline process monitoring, pulseecho ultrasound, ultrasonic velocity profiling, solids concentration, signal processing, windowed Wet LowIntensity Magnetic Separation:

magnetic wet magnetic separation process

Employing wet magnetic separation early in a process can greatly benefit an operation if a lowgrade final tailing, or a clean marketable product, can be produced, since it alleviates both drying and dry storage costs While WHIMS use can be advantageous, a common drawback of conventional designs is entrapment of non magnetics in the magnetics Wet highintensity magnetic separation forthe concentration ofWitwatersrand golduranium oresandresidues essential process for the extraction of gold When concentration isintroduced, itisolates aportion ofthe magnetic separation, and asmall batchtype separator (Eriez model HIW4L) waspurchased in1967,and this Wet highintensity magnetic separation forthe All magnetic system adopts NdFeB and warp angle design, which not only improves the magnetic field intensity, but also increases magnetic turn degree, increases 30% mineral separation efficiency; Therefore, Xinhai won a number of patents, and now has formed complete Xinhai magnetic separation process Magnetic Separation, Magnetic Separation Process,

Eriez Wet Drum Separators

Wet drum magnetic separators are the most vital part of the upgrading process in magnetite concentration The upgrading of primary magnetite is always accomplished with wet drum separators Mill feed is typically upgraded to 65+ percent magnetic iron using a series of wet drum magnetic separatorsDry Magnetic Separation Of Iron Ore Process Dry Magnetic Separation of Iron Ore of the Bakchar Deposit An implementation of twostep concentration afterpurification allowed increasing the iron content in the concentrate up to 482 It forces to upgrade the process of dry magnetic separation or carry it out in the liquid phase socalled wet separation Fig 5 shows the iron ore after the process Drying Magnetite In Wet Separation ProcessEmploying wet magnetic separation early in a process can greatly benefit an operation if a lowgrade final tailing, or a clean marketable product, can be produced, since it alleviates both drying and dry storage costs While WHIMS use can be advantageous, a common drawback of conventional designs is entrapment of non magnetics in the magnetics magnetic wet magnetic separation process

magnetic separation processmagnetic separating

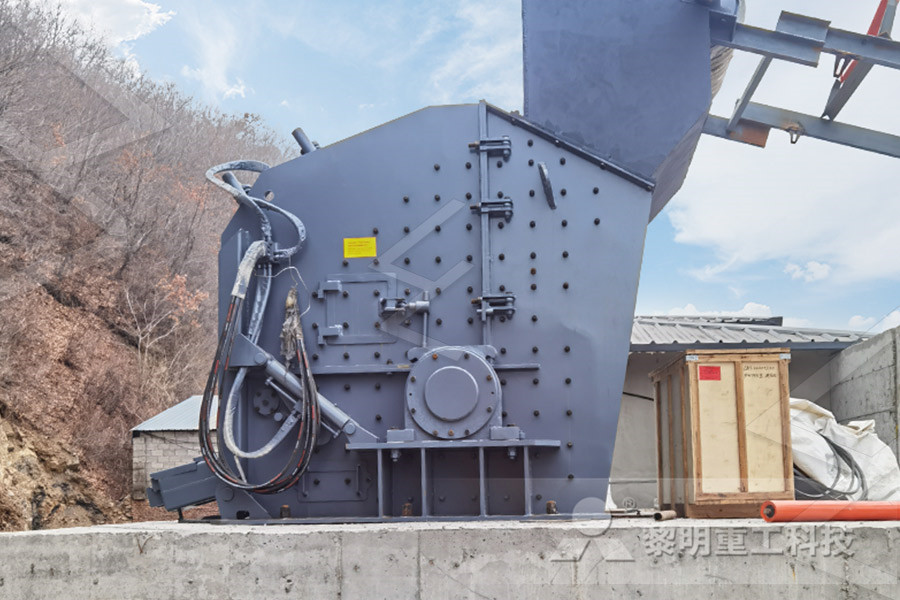

The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation combination method of magnetite The magnetic separation process is mainly a threelevel magnetic separation process for ore powder After wet material magnetic separation, the magnetic field strength selected for magnetic separation is 400 ~ 1200 GS, The magnetic drum rotation speed is 60 to 320 revolutions per minuteMethod And Application Of Magnetic Separation Process Magnetic separation has been used to upgrade and beneficiate variety of industrial minerals The first application of the magnetic separation process on industrial minerals is to remove iron containing compounds and minerals such as hematitelimonite [5], taconite [6], pyrite (FeS 2), and pyrohiotite (Fe 7 S 8) [7]{The wet high intensity magnetic separation of magnesite

Wet highintensity magnetic separation forthe

Wet highintensity magnetic separation forthe concentration ofWitwatersrand golduranium oresandresidues essential process for the extraction of gold When concentration isintroduced, itisolates aportion ofthe magnetic separation, and asmall batchtype separator (Eriez model HIW4L) waspurchased in1967,and this Magnetic separation (MS) equipment is used throughout various industries to upgrade a wide variety of minerals and materials A plethora of technologies exist today from batch and continuous systems to systems that use permanent or electromagnets Both of these systems have their limitationsMagnetic Separation System for Wet and Dry Materials The wet and dry magnetic separation process has specific advantages as well as disadvantages Questions are often raised about which separation technique is most appropriate for a particular ore type or operation The most suitable solution is commonly determined by the required specifications of the end product or a clean marketable productMagnetic separation studies for a low grade siliceous iron

Wet High Intensity Magnetic Separator Mineral

The Reading WHIMS set the industry benchmark for wet magnetic separation of fine minerals They afford the most efficient separation of minerals in slurry form, when drying of the material is undesirable or uneconomical Features Smaller, lighter and more compact than any other WHIMS of comparable capacityAlibaba offers 171 wet magnetic separation equipment products About 16% of these are Mineral Separator, 0% are Separation Equipment A wide variety of wet magnetic separation equipment options are available to you, such as key selling points, applicable industries, and warrantywet magnetic separation equipment, wet magnetic separation