Factors Affecting Plant And Machinary Capacity

Factors Affecting Capacity A Plant Gold Prospecting Pdf factors affecting capacity a plant gold prospecting pdf in chile market Small Scale Gold Mining Equipment In Ghana small scale gold ore cone crusher is widely used in If your aggregate or mining business demands the 24 Get Price Iron ore production may scale new peak Production of iron ore in China the world s biggest consumer of the Production capacity is an important issue for a mechanical machining factoryFor the management of a mechanical processing plant, it is necessary to have a sufficient understanding of the company’s production capacity in order to choose a suitable business and develop at the fastest speed to make the company profitableFactors affecting production capacity in mechanical factors affecting plant and machinary capacity factors affecting determination of plant capacity « mill gold factors affecting determination of plant capacity Description : Jaw crusher machine, operation, working principle, parameter 17 Dec 2012 factors affecting in the factors affecting in the determination of plant capacity

Factors Affecting In The Determination Of Plant Capacity

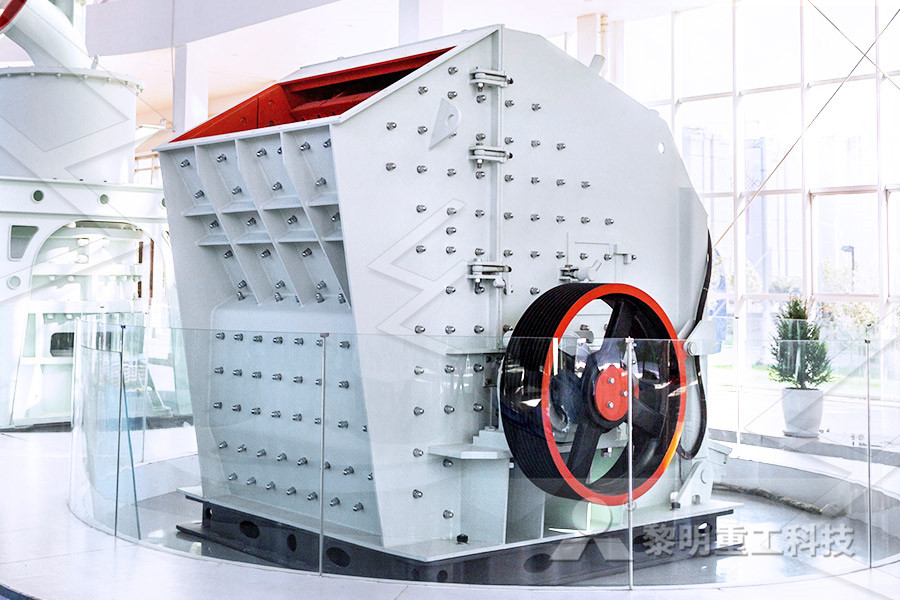

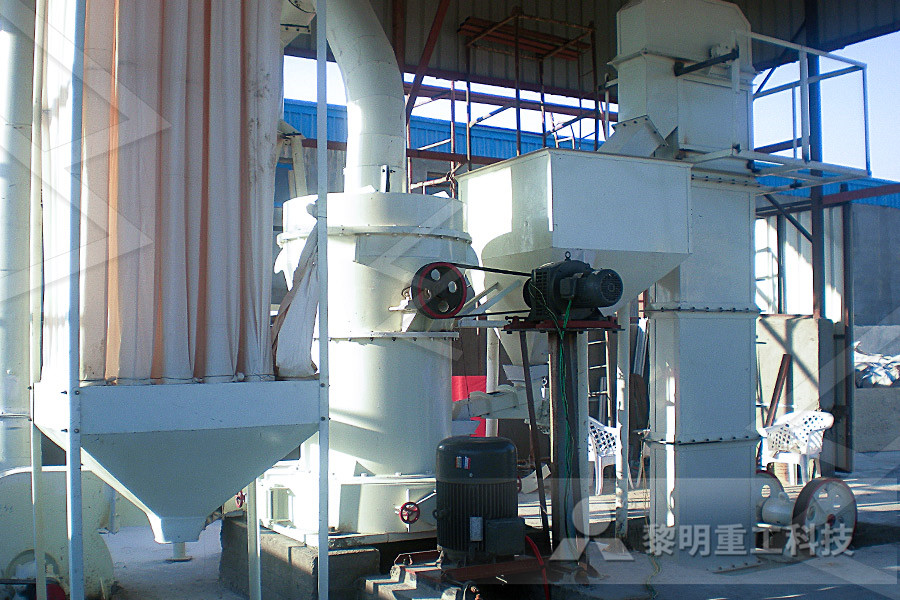

Factors Affecting Plant And Machinary Capacity The primary factors affecting the productivity of crushershe crushing capacity of crushers such as jaw breaker, impactor crusher, hammer crusher etcrefers to the amount of material crushed in the unite time, and its unit is usually tonsh factors affecting plant and machinary capacity Get A Quotefactors affecting determination of plant capacity « mill gold factors affecting determination of plant capacity Description : Jaw crusher machine, operation, working principle, parameter 17 Dec 2012 Factors Affecting Determination Of Plant Capacityfactors affecting plant capacity May 01, 2020 It basically measures how often a plant is running at maximum power A plant with a capacityfactor of 100% means it’s producing power all of the time Nuclear has the highest capacity factor of any other energy source—producing reliable, carbonfree [ protected]factors affecting plant capacity Mining

factors affecting capacity a plant ebmklussennl

factors affecting plant capacity centrostampasrlit factors affecting plant and machinery capacity – , The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction edaphic factors of the plant environment The physical properties include the soil texture, soil structure, and bulk density which affect the capacity of the soil to retain and supply water, while the chemical properties consist of the soil pH and Cation Exchange Capacity (CEC) which determines its capacity to supply nutrients3 FACTORS AFFECTING PLANT GROWTH cel@kau Fig 1 Factors affecting production lines Analyses are carried out by the management on production line problems almost daily and counter measures are taken to further strengthen the performance of the production line Analysis is simplified when data is translated into various categories base on critical factors which affects the production linesMachine efficiency and man power utilization on

Plant Location: 11 Factors that Influence the Selection

ADVERTISEMENTS: Location, localization and planned location of industries are often felt to be synonymous But, the distinction among these three terms is of immense importance Entrepreneurs locate their enterprises where the cost of production comes, the lowest at the time of establishing industries This is known as ‘location of industries’ The concentration of a particular []Factors Affecting Plant And Machinary Capacity – mineral If you are looking to buy mining processing equipment you got to the Factors affecting selection, You may also need to purchase the following machine for »More detailedfactors influencing the selection of purchase of mining Sub: Syllabus of Valuation Examination for Asset Class Plant and Machinery with effect from 1st June 2020 1st June 2020 In pursuance of the rule 5 (3) of the Companies (Registered Valuers and Valuation) Rules, 2017, the Insolvency and Bankruptcy Board of India, being the Authority, hereby publishes the syllabus, format and frequency of the ‘Valuation Examination’ for the asset class Plant and Machinery Valuation Courses IOV RVF

Plant Layout: Meaning, Factors and Tools

ADVERTISEMENTS: After reading this article you will learn about: 1 Meaning of Plant Layout 2 Factors Considered for Plant Layout 3 Analytical Tools 4 Advantages 5 Layout of Services 6 Objectives of Plant Layout and Material Handling 7 Types of Plant Layout Problems 8 Characteristics 9 Principles 10 Factors Influencing 11 Types 12 MachineRequirements 13 []The above factors should be considered in order to improve the health and welfare of employees 6 Service facilities: The layout should provide for the comforts and welfare of the employees It should have adequate provision for rest rooms, drinking water, lavatory There should be sufficient space for free movement of workers 7Top 10 Factors influencing design of plant layout Capacity and capacity utilization will be revised to incorporate data for manufacturing through the fourth quarter of 2020 from the US Census Bureau's Quarterly Survey of Plant Capacity Utilization, along with new data on capacity from the US Geological Survey, the US Department of Energy, and other organizations NoteThe Fed Industrial Production and Capacity

Reactive oxygen species and antioxidant machinery in

Though the plant genome is very stable but its DNA might get damaged due to the exposure to biotic and abiotic stress factors which might damage the DNA, and thereby exerts genotoxic stress Endogenously generated damage to DNA is known as ‘‘spontaneous DNA damage” which is produced by reactive metabolites (OH , O 2 − and NO ) Overview One of the major goals of TPM and OEE programs is to reduce and/or eliminate what are called the Six Big Losses – the most common causes of equipmentbased productivity loss in manufacturing First, let’s define the Six Big Losses Capture the Six Big Losses to gain additional actionable insight to the OEE Factors of Availability, Performance, and QualitySix Big Losses – TPM, OEE, and Improving Productivity Plant responses to abiotic stress were recently shown to be influenced by reciprocal interactions between ROS and auxin, affecting auxin balance and resulting in altered growth (Tognetti et al, 2012) Stress‐induced ROS production can alter auxin gradients in the plant and also reduce auxin‐mediated signaling (Xia et al, 2015)Reactive oxygen species, abiotic stress and stress

Dozers Graders Scrapers Loaders Excavators Cranes

Many factors affect loader production: operator skill, extent of prior loosening of the material, slope of the operating area, height of the material, climate, and haulunit positioning Loader Trick of Trade #1: CUBICYARD ESTIMATES Step 1 Determine the material type and the rated heapedbucket capacity of the loader Step 2 100 mm course plant mixed,spread compacted 357 m3 / hour 4 TRUCKS (Dumper Truck): Dumper Truck Earth moving Equipment •Trucks are an extremely important part of the earthmoving and materialmoving process •They are basically a tractor and a trailer with sides Like the rest of the equipment categories, there are a wide range of trucks Earth moving Equipment function and standard Factors Affecting Plant And Machinary Capacity – mineral If you are looking to buy mining processing equipment you got to the Factors affecting selection, You may also need to purchase the following machine for »More detailedfactors influencing the selection of purchase of mining

Capacity Planning Meaning, Classification and its Goals

Strategic capacity planning is utilized for capital intensive resource like plant, machinery, labor, etc Strategic capacity planning is essential as it helps the organization in meeting the future requirements of the organization Planning ensures that operating cost are maintained at a minimum possible level without affecting the quality Improve Productivity With XL Here is a fascinating and extremely important fact Most equipment is not used anywhere near its true capacity In fact, the difference between typical manufacturing (an OEE score of 60%) and bestinclass manufacturing (an OEE score of 85%) represents an astounding 416% increase in capacityIncrease Manufacturing Production Capacity Vorne Capacity and capacity utilization will be revised to incorporate data for manufacturing through the fourth quarter of 2020 from the US Census Bureau's Quarterly Survey of Plant Capacity Utilization, along with new data on capacity from the US Geological Survey, the US Department of Energy, and other organizations NoteThe Fed Industrial Production and Capacity

5 ways to measure manufacturing equipment

Categorising incidents into these six subsets can help operators better understand the factors that are affecting plant efficiency 5 Overall equipment effectiveness Once you have determined a machine’s availability, performance and quality scores, you can calculate the overall equipment effectiveness (OEE)Mechanization is the process of shifting from working largely or exclusively by hand to do that work using machines The construction projects are becoming more demanding and complicated in construction and delay of projects would arise if conventional construction method is usedMechanization in Construction Industry Motivations, 31 Introduction The unit cost of logging or road construction is essentially derived by dividing cost by production In its simplest case, if you rented a tractor with operator for $60 per hour including all fuel and other costs and you excavated 100 cubic meters per hour, your unit cost for excavation would be $060 per cubic meter3 CALCULATION OF MACHINE RATES FAO

Reactive oxygen species, abiotic stress and stress

Plant responses to abiotic stress were recently shown to be influenced by reciprocal interactions between ROS and auxin, affecting auxin balance and resulting in altered growth (Tognetti et al, 2012) Stress‐induced ROS production can alter auxin gradients in the plant and also reduce auxin‐mediated signaling (Xia et al, 2015) a) Installed capacity b) Actual production c) Licensed capacity d) Utilization capacity Ans (a) 47 Valuing all machines individually out of group of machines in a plant is known as a) Part b) Fraction c) Whole d) Part and Fraction Ans (b) 48 Lowest MODEL QUESTION PAPER FOR VALUATION Solar Evaporation MethodThis is the oldest method of salt production It has been used since salt crystals were first noticed in trapped pools of sea water Its use is practical only in warm climates where the evaporation rate exceeds the precipitation rate, either annually or for extended periods, and ideally, where there are steady prevailing Salt Production and Processing Morton Salt