Magnetic separation: its application in mining, waste

The use of strong magnetic field gradients and high magnetic fields generated by permanent magnets or superconducting coils has found applications in many fields such as mining, solid state chemistry, biochemistry and medical research Lab scale or industrial implementations involve separation The non magnetic particles are moved down to the lower hopper following the gap of the lower magnetic pole and the magnetic separation of magnetic minerals is completed At this point the pulsating box is activated causing the pulp shaking up and down in order to remove impurities and improving the concentration of the pulpMagnetic separation for mining industry – Magnetense Magnetic separation is most commonly used in the mining industry to separate “tramp ore,” or unwanted waste metals, from the rest of the bulk material Tramp ore typically consists of the manmade byproducts created by the mining process itself, such as wires from explosive charges, nuts and bolts, nails, broken pieces from hand tools such Magnetic Separation in the Mining Industry

Materials Special Issue : Magnetic Particles for Use in

Magnetic separation, the use of which started in the mining industry, has in recent years seen a huge expansion in areas of application, including analytical procedures and sample preparation for diagnostic, bioprocessing, food and chemical processing and treatment of effluents, among others To demonstrate the proposed magnetic separation method, 5 μm and 15 μm polystyrene (inherently a diamagnetic material 31) particles from SigmaAldrich were mixed and resuspended in 001 × EMG 408 ferrofluid (Ferrotec Corp) to a final concentration of about 10 7 particles per milliliter The dilute ferrofluid was prepared by mixing the Continuous sheathfree magnetic separation of A: Magnetic separation is a fundamental aspect of both the steel and mining sectors, particularly when ore and gangue minerals have rich iron content Our solutions have applications in several industries but the mining and steel industries have benefited from our products the most, and currently 50% of our products are aimed at supporting Magnetic Separation Raises the Bar in Metal Production

Magnetic Separation of Sulphide Minerals 911

American Institute of Mining and Metal lurgrcal En~neers zg West 39th Street New York N Y Unless special arrangement is made, discussion of this paper will close April I, 1943 Any drscussion offered thereafter should preferably be in the form of a new paper Magnetic Separation of Sulphide Minerals BY A M GAUDIN* However, magnetic separation approaches remain less quantitative than FACS, which can gate on the relative quantity of a biomarker This lack of quantification from traditional MACS is due to the fact that these approaches cannot discriminate effectively based on the number of bound magnetic particlesQuantitative Magnetic Separation of Particles and Ferrofluid speed effects on the magnetic separation of 3 µm and 10 µm polystyrene particles: (a1)–(a3) show the streak images at the outlet of the straight microchannel under the average flow speed of 06 mm/s (a1), 08 mm/s (a2), and 12 mm/s (a3) (other conditions are referred to Fig 3); (b1)–(b4) compare the experimental (symbols) and Magnetic separation of particles and cells in ferrofluid

Magnetic particles for the separation and purification

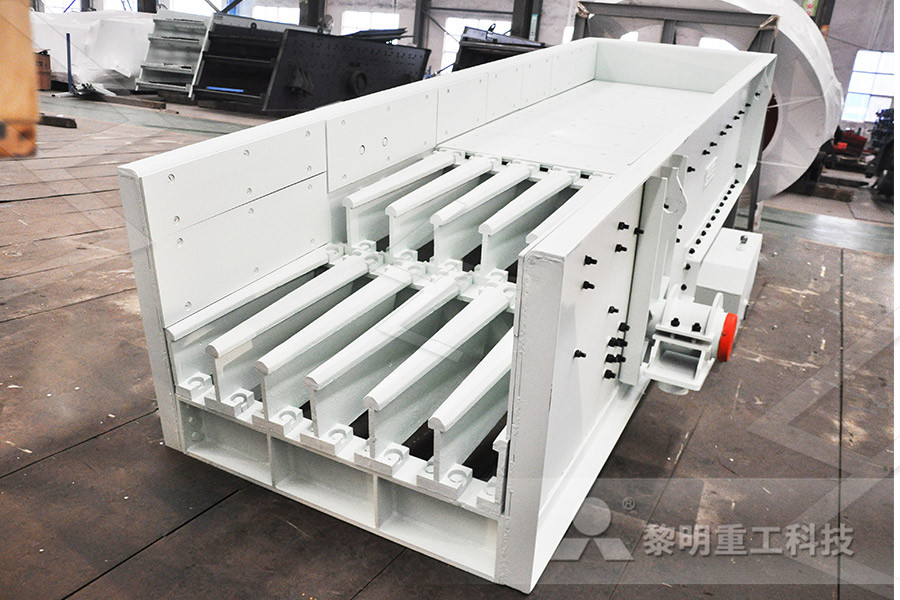

Various types of magnetic particles are commercially available for nucleic acid purification, magnetic separators working in the manual and automated mode are offered A short description of traditional and magnetic separation methods for nucleic acid isolation, together with a short overview of batch and automated separators, will be given belowThe non magnetic particles are moved down to the lower hopper following the gap of the lower magnetic pole and the magnetic separation of magnetic minerals is completed At this point the pulsating box is activated causing the pulp shaking up and down in order to remove impurities and improving the concentration of the pulpMagnetic separation for mining industry – MagnetenseThe technology behind Magnetic Separation in Mining In magnetic separation, the mined substance is put in touch with the magnet or kept extremely close to it But before that, the mined substances are put through Jaw Crusher and Feed Screener to turn the big pieces into small ones and then separating the desired tiny particle for magnetic Magnets Magnetic Separation in Mining @BJ

Magnetic Separation SpringerLink

Abstract Magnetic separation utilizes the force of a magnetic field to produce differential movement of mineral particles through a magnetic field; this and the fundamental differences in the magnetic susceptibility of minerals constitutes the basis of separation to effectively obtain purification or concentration of mineral pared to other minerals , magnetite ore is easier to separate We use normally permanent magnetic separator , magnetic pulley and magnetic dewatering tank ?these process are very easy These years , with the enhance of requirement of fine particles and smelting industry , accelerated the magnetic technology ? including the fine screen ,magnetic column and weak magnetic separator magnetic separation process Yantai Jinpeng Mining A: Magnetic separation is a fundamental aspect of both the steel and mining sectors, particularly when ore and gangue minerals have rich iron content Our solutions have applications in several industries but the mining and steel industries have benefited from our products the most, and currently 50% of our products are aimed at supporting Magnetic Separation Raises the Bar in Metal Production

magnetic separation examples pocedure and materials

Magnetic particles for the separation and Magnetic separation of nucleic acids has several advantages compared to other techniques used for the same purpose Nucleic acids can be isolated directly from crude sample materials such as blood, tissue homogenates, cultivation media, water, etc Magnetic separation is widely used in mineral processing to separate valuable minerals from gangue minerals using the magnetic properties of the minerals []It is also used for processing waste material as for the separation of polymer []Magnetic separators can be divided into low and high intensity separators and high gradient magnetic separators []Simulation of a Dry Magnetic Separation Plant Magnetic Density Separation of Polymers Urban Mining Corp Gebouw ‘De Coopvaert’ Blaak 520, 3011 TA Rotterdam, The Netherlands umincorp , info@umincorp, Tel: +31 10 Magnetic Density Separation of Polymers

Selective Capture of Magnetic Wires to Particles in

High gradient magnetic separation (HGMS) achieves effective separation to fine weakly magnetic minerals using numerous small magnetic wires in matrix, and its separation performance is inherently dependent on the capture characteristics of the wires In this work, the selective capture of magnetic wire to particles in high gradient magnetic field was theoretically described and simulated using It should be pointed out that magnetic particles are not solely used for separation purposes From a literature search, without any application restrains, in the Thomson Reuters’ of Knowledge SM using the terms “magnetic particles”, “magnetic beads” and “magnetic nanoparticles” we can clearly see a significant increase in the number of publications in the last 20 years ()Magnetic separations in biotechnology ScienceDirectThe non magnetic particles are moved down to the lower hopper following the gap of the lower magnetic pole and the magnetic separation of magnetic minerals is completed At this point the pulsating box is activated causing the pulp shaking up and down in order to remove impurities and improving the concentration of the pulpMagnetic separation for mining industry – Magnetense

magnetic separation of minerals

Magnetic separation of coal fly ash from Bulgarian power plants584 Кб Among the fly ash characteristics, the most important parameters, determining the magnetic separation applicability, were mineralogical composition and distribution of minerals in particles When implemented correctly, magnetic separation offers an opportunity to recover a variety of valuable minerals residing in host ore Magnetic susceptibility Magnetic susceptibility is a measure of how susceptible a mineral is to a magnetic field The higher the magnetic susceptibility, the stronger the force of attraction to a magnetic fieldMagnetic separation – an attractive sorting optionThe magnetic separation is useful to select and to condense superconducting particles from a sintered specimen including nonsuperconducting components Key Words YBaCuO superconductor fine particles magnetic separation Central Research Laboratory Dowa Mining Co, Ltd Hachioji, Tokyo, 192 Japan; About this paperMagnetic Separation of HighTc Superconducting

Optimizing the performance of wet drum J magnetic

magnetic separation All minerals can be generally classified as ferromagnetic (strongly magnetic), paramagnetic (weakly magnetic) or diamagnetic (nonmagnetic) Magnetic separation can be conducted dry or wet The majority of the applications of wet magnetic separation in the mining industry are based on the wet drum magnetic separator Magnetic Density Separation of Polymers Urban Mining Corp Gebouw ‘De Coopvaert’ Blaak 520, 3011 TA Rotterdam, The Netherlands umincorp , info@umincorp, Tel: +31 10 Magnetic Density Separation of PolymersHigh gradient magnetic separation (HGMS) achieves effective separation to fine weakly magnetic minerals using numerous small magnetic wires in matrix, and its separation performance is inherently dependent on the capture characteristics of the wires In this work, the selective capture of magnetic wire to particles in high gradient magnetic field was theoretically described and simulated using Selective Capture of Magnetic Wires to Particles in

Magnetic separations in biotechnology ScienceDirect

It should be pointed out that magnetic particles are not solely used for separation purposes From a literature search, without any application restrains, in the Thomson Reuters’ of Knowledge SM using the terms “magnetic particles”, “magnetic beads” and “magnetic nanoparticles” we can clearly see a significant increase in the number of publications in the last 20 years ()USA US05/592,195 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords magnetic particles separation population select recited Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Magnetic separation of biological Many of the particles encountered in mining are characterized by sieves (classifiers) Recent advances in computers, cameras, and software make image analysis practical for samples with sizes larger than several microns in diameter As particle size decreases, sieving and/or dynamic image analysis becomes more arduous or impossible and laser diffraction becomes the technique of choiceParticle Analysis in Mining and Minerals HORIBA