Graphite ANZAPLAN

Processing steps in the development of a flowsheet targeting the concentration and downstream processing of graphite will involve physical, thermal and chemical processing steps Main physical processing steps applied: Comminution; Flotation; Micronization; Spheroidization (spherical graphite) Intercalation (expandable graphite) According to the USGS, US (synthetic) graphite production in 2006 was 132,000 tonnes valued at $495 million and in 2005 was 146,000 tonnes valued at $391 million, and highmodulus graphite (carbon) fiber production in 2006 was 8,160 tonnes valued at $172 million and in 2005 was 7,020 tonnes valued at $134 million 2 Modern ManufactureOpen Knowledge Wiki Manufacturing and 1 RAW MATERIALS Coke (approximately 7580% in content) Petroleum coke is the most important raw material, and it is formed in a wide range of structures, from highly anisotropic needle coke to GRAPHITE ELECTRODES Manufacturing Process

Artificial Graphite an overview ScienceDirect Topics

Graphite anodes work in a potential range of 50–200 mV vs Li/Li + with a specific capacity of about 350 Ah kg −1 at good price, stability, and security, but moderate power On charging highly graphitized carbon, the potential drops rapidly to near 08 V vs Li/Li + , where the potential remains nearly constant Mersen is a world leader in isostatic graphite production, and proposes proven solutions to each step of the photovoltaic production chain, from polysilicon feedstock to cells antireflective coating via thin film process • Its range of materials covers graphite, Carbon/Carbon composite as Graphite grades MersenSIGRAFLEX ® highpurity graphite foil and sheets made from expanded natural graphite are suitable to produce heat shields, insulation materials, flexible release layers, and sealing materials SIGRAFLEX flexible graphite is also often used in in combination with SIGRATHERM rigid felts, SIGRABOND carbon fiberreinforced carbon and SIGRAFINE artificial graphiteGraphite materials for polysilicon production SGL

Development Graphite/ Polyimide Honeycomb Core

use temperatures will range up to 316OC (6OO0F), graphite core incorporating polyimide resins would be substituted for the relatively expensive titanium brazed honeycomb constructionsRoll form available, Patented edgesealing process 定制下载附件表 Download High thermal conductivity, can be up to 150 to 1500 W/mK@XY axis and 15 W/mK@Z axis Max 200m length and 400mm width roll form available Patented Envelope Sealing (edgesealing) process Sheet form, die Graphite Film solutions Shenzhen FRD Science The graphite electrode is a type of conductive medium used as the two ends of inputting or outputting the electric current And this type of conductive medium is made of the material of graphite During the electric furnace steelmaking process, it is necessary to transform the energy of electricity into heat to make the steal meltApplication Range of the Graphite Electrode Huaruo

Production Process of Graphite Electrode

Production Process of Graphite Electrode Raw Material and Manufacturing Technology of Graphite Electrode Graphite electrode is a kind of graphite conductive material with high temperature 1 RAW MATERIALS Coke (approximately 7580% in content) Petroleum coke is the most important raw material, and it is formed in a wide range of structures, from highly anisotropic needle coke to GRAPHITE ELECTRODES Manufacturing ProcessGraphite is a key component of a range of everyday things from batteries, brakes and refractory bricks, to lubricants, fire retardants, inks and electronics It is used extensively across the steel, automotive, aircraft, electronics, energy and nuclear industries Process innovation for a range of deposits and mineralsGraphite goes green CSIRO

Graphite Permanent Mold Casting Graphite Mold Casting

Graphite mold casting has become the preferred choice in industrial applications for its flexibility It can be applied to a wide range of quantities while delivering close tolerances for the most complex parts The graphite permanent mold casting process begins with pneumatically clamping two graphite blocks in a Our HCMSeries® has a wide variety of graphite grades that can be selected individually depending on their intended use In general, diepressed graphite grades offer a wide range of technical properties in terms of mechanical strength, friction, density, hardness and electrical conductivityGRAPHIT HexagonCronite offers a wide range of methods and materials to suit every process requirement, it includes: Composite C/C 2D 3D (including special coatings) Graphite extruded isostatic; We provide a range of standard products like CFC baskets and customized solutions We also supply hybrid solution, combination of casting, composite graphiteCFC Graphite Cronite Group

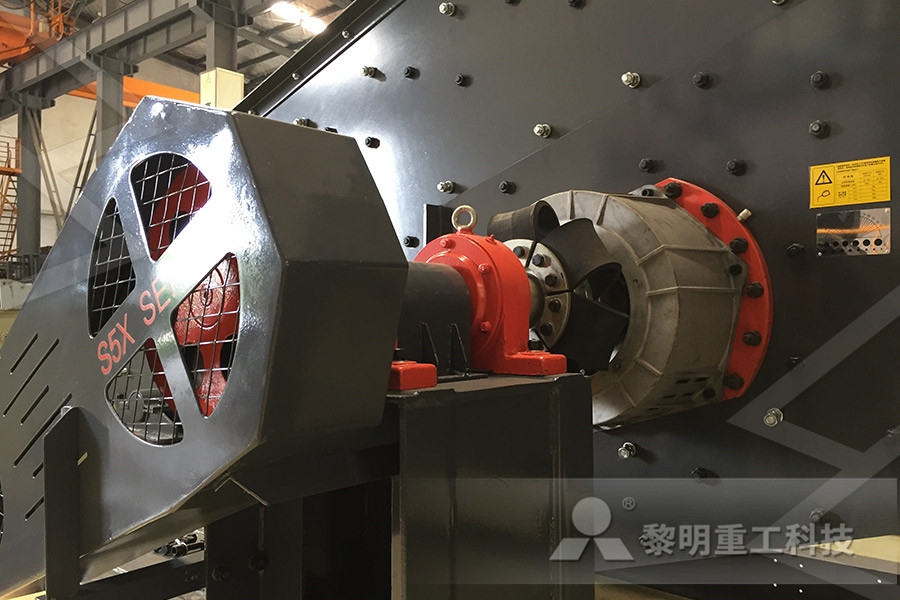

Graphite Plant International Graphite

The modular design of our Collie facility involves two integrated processing streams that will manufacture a range of high quality graphite products The plant will use proven technologies, including equipment sourced from established international suppliers, to ensure fast, lowrisk startup, early revenue and to minimise capital costs The graphite submicroflakes are successfully synthesized by reacting CO 2 with LiAlH 4 at the temperature range of 126–876 °C within several seconds in the absence of transition metal catalysts Green synthesis of graphite from CO 2 without To test the potential suitability of the Burke graphite for use in lithiumion batteries (and other applications), an industry standard graphite flotation process was applied to core samples taken at a depth of 410 – 565 metres from diamond drill hole BGDD001(English) Burke Graphite Project strikeresourcesau

Graphite Beneficiation Process 911 Metallurgist

Graphite Beneficiation Process Market Specifications Crucible grade flake graphite has a size range of 20 to 50 mesh and contains 83 to 90 per cent carbon Production Problems The production of a coarse, tough flake product with the desired impurity removal is necessary Flotation is successful, but special reagents may be necessary to Finegrain graphite Some special property combinations of graphite can only be obtained if finegrained solids are used Therefore, the socalled finegrain graphite was developed, which is produced by a grinding process Finegrain graphite is graphite with a grain size of less than 1 mmEverything About Graphite SGL Carbon Modern graphite manufacture commences with a high molecular weight hydrocarbon, often natural pitch or a residue of crude oil distillation, which is first converted to coke by heating in the absence of air This is long and complex process, usually taking several weeks to performOpen Knowledge Wiki Manufacturing and

CFC Graphite Cronite Group

Cronite offers a wide range of methods and materials to suit every process requirement, it includes: Composite C/C 2D 3D (including special coatings) Graphite extruded isostatic; We provide a range of standard products like CFC baskets and customized solutions We also supply hybrid solution, combination of casting, composite graphiteBy way of contrast, the CarbonScape process is fully controllable By changing the properties of the catalyst and the reaction conditions the morphology of the graphite product can be tailored across a wide range of microstructures In this way the graphite can be CarbonScape Graphite — CarbonScapeThe Siemens Process Polysilicon is produced on an industrial scale mainly by the Siemens process This is a chemical vapor deposition (CVD) based process, in which highly purified silane gases such as trichlorosilane (TCS) are heated in the presence of silicon rodsGraphite materials for polysilicon production SGL

Controlled synthesis of graphite oxide: Formation

The above results indicate that the oxidation of FG is a solidstate diffusion controlled reaction process (Dimiev and Tour, 2014) when the initial mass of KMnO 4 is sufficient, and the study of α graphitebased oxidation kinetics is a direct and accurate way to investigate the oxidation process Graphite Gasket Materials We stock a wide range of graphite gaskets sheet materials from industrial to nuclear grade that is 95% pure carbon Graphite materials can be inserted or coated with various metal core elements, which improve flexibility, strength and stability for improved performance in extreme environmentsGraphite Gasket Manufacture Wide Range of Roll form available, Patented edgesealing process 定制下载附件表 Download High thermal conductivity, can be up to 150 to 1500 W/mK@XY axis and 15 W/mK@Z axis Max 200m length and 400mm width roll form available Patented Envelope Sealing (edgesealing) process Sheet form, die Graphite Film solutions Shenzhen FRD Science

Fast anion intercalation into graphite cathode

In the discharge process, TFSI − anions deintercalate from graphite cathode and diffuse back into the electrolyte while Zn 2+ cations dissolute from Zn anode A very recent work by Feng et al presented a similar Zn/graphite battery configuration combining Zn plating/stripping and anion (de)intercalation into graphite [ 32 ]