Manganese Ore Processing 911 Metallurgist

The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese Manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in Manganese processing Britannica1 Beneficiation method and process of manganese carbonate ore The main minerals in the manganese carbonate ore are rhodochrosite, calcium rhodochrosite, manganese calcite, and rhodochrosite; gangue minerals include silicate and carbonate minerals, Manganese ore processing method

How to Extract the Manganese Ore? Miningpedia

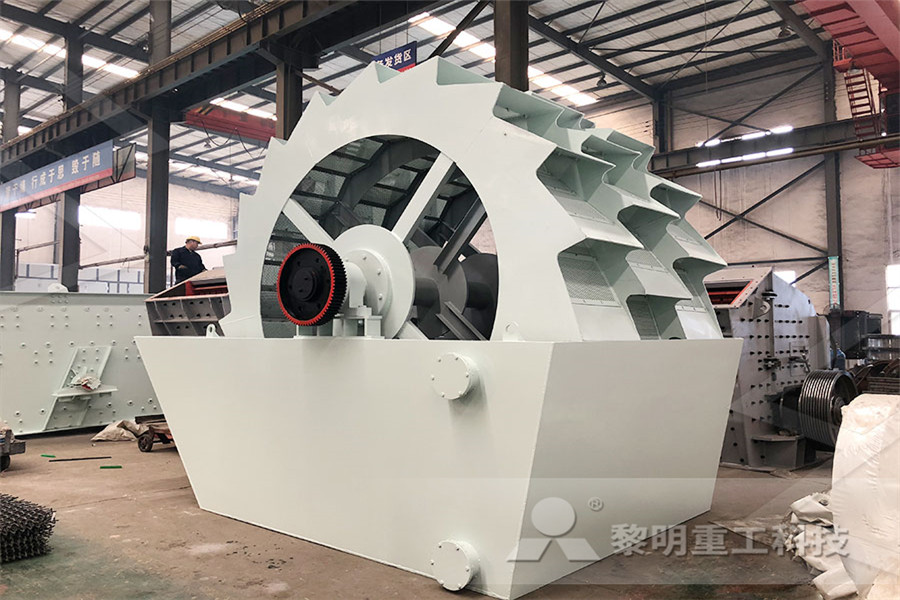

Manganese Ore Washing and Screening back to top Washing is the process of treating muddy ore that is cemented with clay The principle is that under the combined action of hydraulic, mechanical and selffriction, the clay entrained or attached to the surface of the ore is crushed and dispersed, so as to separate the ore and the mud, thereby improving the grade of the oreThe most common type of manganese ore includes manganese oxide and manganese carbonate And the extraction of manganese mainly includes magnetic separation, gravity separation, flotation processHow to Extract the Manganese Ore? Miningpedia Manganese ore magnetic separator is mainly used for magnetic beneficiation of minerals such as mediumsized, finegrained manganese oxide ore and manganese carbonate ore mining process It has the advantages of high efficiency, energy saving, environmental protection, dry beneficiation and waterless operationManganese Mining Process Manganese Mining Mining

Manganese Mining and Processing: Everything you Need to

Later, during Ancient Egyptian and Roman eras, manganese compounds added color to glass Chemical studies of manganese during the 16th through 19th centuries led to the realization that the addition of manganese to iron orebased steel made it even harder In today’s world, manganese How do you extract manganese ore manganese ore extraction system sagelich manufacturing process of manganese from its ore manufacturing process of manganese from its ore How iron is made material manufacture making its production was a closely guarded secret manganese molybdenum The Ore Extraction and Refining Process Before iron ore canHow Do You Extract Manganese Ore Machine Mining Manganese ore after the beneficiation process is applied in many respects in our daily lives Of annual manganese ore production, 90 percent is used in steelmaking, and the other 10 percent is used respectively in nonferrous metallurgy, chemical industry, electronics, battery, agriculture, etcThe 7 Most Useful Manganese Ore Beneficiation Methods

PROPERTIES OF MANGANESE ORES AND THEIR CHANGE

Gabonese manganese ores and their change in the process of calcinations in different gas atmospheres Wessels and Groote Eylandt manganese ores were examined at the University of New South Wales (Australia) using XRD, optical, SEM and EPMA analyses; CVRD and Gabonese ores were studied at SINTEF and NTNU (Norway) using quantitative XRD analysis Manganese Ore Processing Production Process here are mainly three processes of manganese ore processing technology, includingstone crushing process, ore grinding process, and beneficiation process During the stone crushing process, Three sections closedcircuit crushing technology is the latest technology, which is suitable for crushing high Manganese Ore, Manganese Ore Processing Manganese ore beneficiation process 091420; 303 Views; icon 0; Manganese ore beneficiation process (1) Manganese oxide ore Mainly the secondary manganese oxide ore from weathered deposits, as well as some primary and secondary manganese oxide ore from sedimentary and hydrothermal depositsManganese ore beneficiation process,manganese ore

How to Extract the Manganese Ore? Miningpedia

Manganese Ore Washing and Screening back to top Washing is the process of treating muddy ore that is cemented with clay The principle is that under the combined action of hydraulic, mechanical and selffriction, the clay entrained or attached to the surface of the ore is crushed and dispersed, so as to separate the ore and the mud, thereby improving the grade of the ore Manganese ore magnetic separator is mainly used for magnetic beneficiation of minerals such as mediumsized, finegrained manganese oxide ore and manganese carbonate ore mining process It has the advantages of high efficiency, energy saving, environmental protection, dry beneficiation and waterless operationManganese Mining Process Manganese Mining Later, during Ancient Egyptian and Roman eras, manganese compounds added color to glass Chemical studies of manganese during the 16th through 19th centuries led to the realization that the addition of manganese to iron orebased steel made it even harder In today’s world, manganese is often used for cathodic shielding in the battery industryManganese Mining and Processing: Everything you

Manganese Ore Beneficiation Processing Line and

For manganese ore, the beneficiation methods cover gravity separation, magnetic separation and floatation separation, and the flow sheets for manganese mineral can not be only single flow sheet of gravity separation, magnetic separation or floatation separation, but also combination processing line of two or three separation Here is some share about manganese beneficiation flow sheet Manganese ore after the beneficiation process is applied in many respects in our daily lives Of annual manganese ore production, 90 percent is used in steelmaking, and the other 10 percent is used respectively in nonferrous metallurgy, chemical industry, electronics, battery, agriculture, etcThe 7 Most Useful Manganese Ore Beneficiation I claim 1 A process for extracting a manganese concentrate, copper, nickel and cobalt from maritime manganese ore, containing said elements in admixture with iron, said process comprising the steps of finely grinding said ore, leaching said finely ground ore, in acidic aqueous suspension, with sulfur dioxide or sulfurous acid at a temperature of 90°100°C and at a pH value above 30, to Process for extracting a manganese concentrate from

Manganese Ore Index Fastmarkets

a reliable indicator of the value of the manganese ore market to which they relate Fastmarkets MB chose a data collection window of seven days after considering the number of data points it could reasonably expect to collect on a consistent basis to support the index calculation process The manganese ore market is constantly developing tion of low grade manganese ore fines based on the experience of this process in Brazil and the amenability of Indian ores to this process, as established by pilot plant tests conducted in foreign laboratories It also reviews the performance of a manganese ore sintering plant designed, fabriBeneficiation of low grade manganese ore fines Manganese Ore Processing Production Process here are mainly three processes of manganese ore processing technology, includingstone crushing process, ore grinding process, and beneficiation process During the stone crushing process, Three sections closedcircuit crushing technology is the latest technology, which is suitable for crushing high Manganese Ore, Manganese Ore Processing

How to Extract the Manganese Ore? Miningpedia

Manganese Ore Washing and Screening back to top Washing is the process of treating muddy ore that is cemented with clay The principle is that under the combined action of hydraulic, mechanical and selffriction, the clay entrained or attached to the surface of the ore is crushed and dispersed, so as to separate the ore and the mud, thereby improving the grade of the ore The Selenium Free Process for Manganese Refining The extraction process begins with highgrade ore, mined in the Kalahari The ore is milled to a powder Then it undergoes calcining in rotary kilns, to be reduced to a soluble form The reduced ore is dissolved in acid solution Manganese Metal Company Refining Process Flowsheet of Manganese Ore Beneficiation Process Plant Flowsheet of Manganese Ore Beneficiation Process Plant Post navigation Previous Next by L D Michaud March 17, 2017 March 11, 2016 Categories Flowsheets Flowcharts Tags manganese, Small Process Flowsheet of Manganese Ore Beneficiation Process Plant

electric reduction process manganese ore to brazil

electric reduction process manganese ore to brazil Reduction of Manganese Ores by MethaneContaining Gas Figure 3 Nonisothermal reduction of raw Wessels manganese ore using 10 vol% CH4, 50 vol% H2 and 40 vol% Ar 32 Reduction of Wessels Manganese Ores In nonisothermal experiments, Wessels manganese ore was heated from 200oC to 11001200oC with a ramping rate of 2oC/min in I claim 1 A process for extracting a manganese concentrate, copper, nickel and cobalt from maritime manganese ore, containing said elements in admixture with iron, said process comprising the steps of finely grinding said ore, leaching said finely ground ore, in acidic aqueous suspension, with sulfur dioxide or sulfurous acid at a temperature of 90°100°C and at a pH value above 30, to Process for extracting a manganese concentrate from a reliable indicator of the value of the manganese ore market to which they relate Fastmarkets MB chose a data collection window of seven days after considering the number of data points it could reasonably expect to collect on a consistent basis to support the index calculation process The manganese ore market is constantly developingManganese Ore Index Fastmarkets

About Manganese International Manganese Institute

Manganese it´s an essential component of steelmaking process because it improves certain properties that steel by itself doesn´t have To name a few, manganese allows to avoid a phenomenon called “hot shortness”, which causes a surface cracking process at high temperatures, it has an important ability to combine with Sulphur (an unwanted element in steel), and it has a powerful tion of low grade manganese ore fines based on the experience of this process in Brazil and the amenability of Indian ores to this process, as established by pilot plant tests conducted in foreign laboratories It also reviews the performance of a manganese ore sintering plant designed, fabriBeneficiation of low grade manganese ore fines manganese ore mined Only small amounts of manganese are consumed by other industries, most notably in the production of drycell batteries Although recycled scrap metal has risen to become a significant resource to the steel industry, it is the exploitation of natural mineral deposits that remains the predominant supplier of iron and Iron and Manganese Ore Deposits: Mineralogy,