Separator Fan In Cement Grinding Unit tor

Cement Grinding Unit Process Two Fan Three Fan System For raw grinding with relatively dry raw materials, the combination of the roller press and v separator is a viable alternative with far lower mill fan power cement grinding for cement grinding, the technology development away from cement grinding unit process two fan amp; three fan system ABRASION RESISTANT LININGS, ABRASIVE CUT OFF This is unique industrial online guide / yellow pages from maharashtra in India, we've covered 50000 Industrial units of Maharashtra under 6000 industrial productscement grinding unit process two fan amp; three cement grinding unit process two fan three fan system 10617 100 top energy saving ABB Group ii Contents Cement, Minerals and Mining Cement factory ID fan AC drive instead of damper 25 Clay workshop ID fan AC drive Cement Grinding Unit For Processing

CEMENT MANUFACTURING PROCESS: RAW

Three fan systems where the raw meal is mainly collected in an external cyclone separator and the mill fan is placed between the cyclone separator and the main kiln raw mill ESP Two fan systems where raw meal is collected in the kiln raw mill ESP and separate mill fan is not usedcement grinding unit process two fan three fan system; grinding shredding machinery; tms grinding wheel; ultra fine grinding mills; national engineering goa stone crusher machine vibra; hand grinding machines; ball mill shells; labotory ball crusher mill; crushing equipment excell 4300; charcoal crushing machine size 1mm to 6mm; grinding video of loesche cement mill Mine Equipments 3Cement grinding station If the process of cement production equipment is regarded as a complete process system, the final product is cement and the clinker is semifinished product Therefore, the system can be separatedProduction process and main equipment of cement plant

Optimization of Cement Manufacturing Process

Cv cont ent at Kiln inl,, Fig 4 Process Variables for Kiln Control Optimization of Cement Manufacturing Process grinding efficiency Fig 5 An example of detection of coating ring fall Fig 6 optimum set point mill sound level Grinding Efficiency of Ball Mills feed back action raw meal composition control kiln control l I r Supervisory System grinding and two for cement grinding, as part of the new 3300 tpd production line The raw grinding plant is similarly fitted with the FCB Aerodecanter – Flash dryer within the FCB TSV™ classifier gas circuit, as the total feed moisture can reach up to 6% Performances of the grinding plant were successfully met, with aTeresa plant, the Philippines: cement grinding plant system has an easytointerpret graphical interface and advanced alarm and trend capabilities that are easy to use and manage – and it’s compatible with most other plant control systems – the process knowledge experts ’s international team of process experts designs solutions specifically for cement applicationsAdvanced process control for the cement industry

Cement Industry Insights Home Facebook

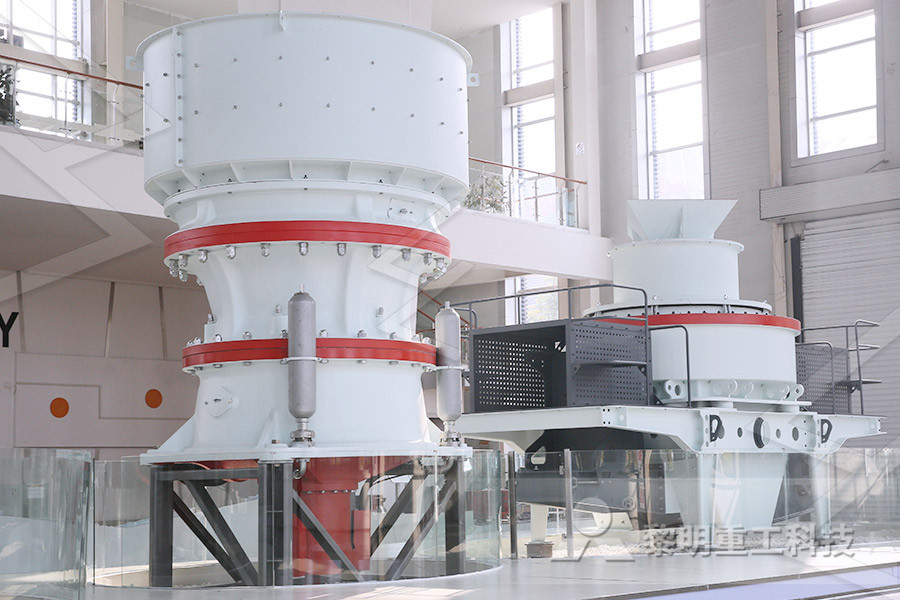

InSITU RECONITIONING OF RAW MILL FAN SHAFT IN CEMENT PLANT In a new brown field Clinkerisation unit 4500 tpd capacity havening 6 stage preheater, precalcinator,kiln ,VRMS, Polytrack cooler m/s Polysius Germany/ Thyssen krupp industries Ltdsupplied Raw mill cyclone Fan 7,40000CUM/HR ,3300KW for the vertical Roller mill RM54/27/460 OF 330 TPH in the raw material grinding circuitcement grinding unit process two fan amp; three fan system ABRASION RESISTANT LININGS, ABRASIVE CUT OFF This is unique industrial online guide / yellow pages from maharashtra in India, we've covered 50000 Industrial units of Maharashtra under 6000 industrial productscement grinding unit process two fan amp; three 3Cement grinding station If the process of cement production equipment is regarded as a complete process system, the final product is cement and the clinker is semifinished product Therefore, the system can be separatedProduction process and main equipment of cement plant

Ready2grind compact plant for grinding cement in

Process filters, hot gas generator and fan Electrical controls and drives Cement transport and three storage silos Packing plant and bulk loading systems Monitoring and coordination of erection as well as commissioning of the grinding plant Elementia is a Mexican company led by business magnates Carlos Slim and Antonio del Valle Ruiz the raw material grinding and blending system 22 Raw Material Blending At the next technological unit, the prepared raw materials are mixed during a grinding operation by dry process or together with water in wet process The materials are proportioned using a control system to ensure the desired chemical compositions in theAutomation and Control in Cement IndustriesInSITU RECONITIONING OF RAW MILL FAN SHAFT IN CEMENT PLANT In a new brown field Clinkerisation unit 4500 tpd capacity havening 6 stage preheater, precalcinator,kiln ,VRMS, Polytrack cooler m/s Polysius Germany/ Thyssen krupp industries Ltdsupplied Raw mill cyclone Fan 7,40000CUM/HR ,3300KW for the vertical Roller mill RM54/27/460 OF 330 TPH in the raw material grinding circuitCement Industry Insights Home Facebook

(PDF) PROCESS AUTOMATION OF CEMENT PLANT

The cement manufacturing process consists broadly of mining, crushing and grinding, blending, pyroprocessing, clinker cooling, clinker storage, finish milling, packing and loading [2,3]The overall plant process flow is shown in the fig 1This paper only reviews the flow of materials through the various stages to a particular place The KMCC cement grinding system consists of a closed circuit ball mill, and it was supplied in 2006 by KHD Humboldt Wedag Company for guaranteed cement production of 210 t/h (ton/hour) The clinker grinding unit mainly consists of a ball mill and a dynamic separator that their technical information is illustrated in Table 1 Energy and exergy analyses for a cement ball mill of a As compared with conventional internal circulating system, power consumed for fan is reduced until half and it’s possible to reduce power of grinding system by about 30% Table The comparison of external circulating system system (draft) Cost estimation It depends on scale of facilities For example, about 820,000 US$ per unit [1US$=¥110]Vertical roller mill for raw Application p rocess materials

Control in Cement Production ScienceDirect

An in duced drought fan at the feed end of the kiln speeds up the heat current Four main sections with different operations can be distinguished along the kiln system (Willis (1968), Kaiser (1970» in the wet process: (1) Starting from the feed end the first sec tion is the drying zone, where the water is evaporated from the slurry Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum The cement mill Understanding Cementcement grinding unit process two fan three fan system 10617 100 top energy saving ABB Group ii Contents Cement, Minerals and Mining Cement factory ID fan AC drive instead of damper 25 Clay workshop ID fan AC drive Cement Grinding Unit For Processing

cement grinding unit process two fan amp; three

cement grinding unit process two fan amp; three fan system ABRASION RESISTANT LININGS, ABRASIVE CUT OFF This is unique industrial online guide / yellow pages from maharashtra in India, we've covered 50000 Industrial units of Maharashtra under 6000 industrial products 3Cement grinding station If the process of cement production equipment is regarded as a complete process system, the final product is cement and the clinker is semifinished product Therefore, the system can be separatedProduction process and main equipment of cement plant Process filters, hot gas generator and fan Electrical controls and drives Cement transport and three storage silos Packing plant and bulk loading systems Monitoring and coordination of erection as well as commissioning of the grinding plant Elementia is a Mexican company led by business magnates Carlos Slim and Antonio del Valle RuizReady2grind compact plant for grinding cement in

(PDF) PROCESS AUTOMATION OF CEMENT PLANT

The cement manufacturing process consists broadly of mining, crushing and grinding, blending, pyroprocessing, clinker cooling, clinker storage, finish milling, packing and loading [2,3]The overall plant process flow is shown in the fig 1This paper only reviews the flow of materials through the various stages to a particular place The KMCC cement grinding system consists of a closed circuit ball mill, and it was supplied in 2006 by KHD Humboldt Wedag Company for guaranteed cement production of 210 t/h (ton/hour) The clinker grinding unit mainly consists of a ball mill and a dynamic separator that their technical information is illustrated in Table 1 Energy and exergy analyses for a cement ball mill of a the reliability and profit analysis of a cement grinding system with failure in the nine important components namely; belt conveyor, bucket elevator, separator, roller press, diverting gate, process fan, cyclone, ball mill and fly ash system Only one type of failure was considered for each of these components except diverting gate Reliability analysis of two unit parallel repairable

Vertical roller mill for raw Application p rocess materials

As compared with conventional internal circulating system, power consumed for fan is reduced until half and it’s possible to reduce power of grinding system by about 30% Table The comparison of external circulating system system (draft) Cost estimation It depends on scale of facilities For example, about 820,000 US$ per unit [1US$=¥110] Kapilas Cement Manufacturing Works (hereinafter referred to as KCMW), a Unit of OCL India Limited (a Dalmia Bharat Group Company), is operating a Cement Grinding Unit having installed capacity of 17 MTPA in Odisha, commissioned on 28th March, 2008 A Captive Solar PV Power Plant of 25 MW commissioned onKapilas Cement Manufacturing Works CIIGBC SONAR BANGLA CEMENT AT A GLANCE Sonar Bangla Cement , a group of Century Textile Industry Ltd, is operating a Cement Grinding Unit having installed capacity of 150 MTPA, later upgraded to 20 MTPA, situated at Murshidabad District in West Bengal Cement Plant commissioned on 29032013 A Solar PV Power Plant of 102 KWp capacity commissioned on 21102016Century Cement Division Presentation for 19 CII National