What are the main factors that influence stone crusher

Oct 04, 2016 Stone crusher is an indispensable equipment for mining crushing production line The output of crusher directly determines the quality and capacity of entire production line The capacity represents that how many stone had been crushed in an hour The capacity unit is described as t/h And it’s capacity is influenced by many factors The The Technical Level is a Key Factor Affecting the Stone Crusher Machine Price The technical content of stone crusher equipment is the key factor in the equipment selection process, and also an important embodiment of the crushing machine priceThree Major Factors Affecting the Stone Crusher Machine PriceWhen the material containing large amount of moisture, materials are easy to attach to the rock crusher, and is easy to stem the transporting pine, then decrease crushing capacity 3 Fineness of materials after crushing The higher fineness requirements are, the lower crushing capacityFactors Influencing Rock Crusher Working Efficiency

How To Choose An Industrial Stone Crusher In The Market

If you’re in the market for an industrial stone crusher, these are a few of the factors that you should be taking into consideration No matter what equipment you ultimately purchase, you should make sure you ultimately invest in something that you’ll be fully satisfied withMar 28, 2019 Before choosing the stone crusher machine to work with, it’s important to consider the character of the source material The characteristic is about the hardness of the stones to be crushed As it affects the general strength needed, it allows you to know which kind of How To Go About Choosing A Stone Crusher MachineBased on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher The main objective is to design impact stone crusher Impact stone crusher involves the use of impact rather than pressure to crush materialsDesign of impact stone crusher machine Impact Factor

Design of impact stone crusher machine Impact Factor

Impact stone crusher is used with soft materials, medium to hard stones and medium hard metallic ores factor as follows [2] a Primary crusher The raw material from mines is processed first in primary crushers The input of these crushers is relatively wider and the output products are coarser in size b Secondary crusher:Mar 28, 2019 To produce the very best of products in quarrying for the construction industry, choosing the right kind equipment is essential However, while considering which stone crush manufacturer, to choose from, it is important to remember that there are different equipment’s for various stages in stone productionAs expected, selecting the right kind of stone crusher improves productivity and How To Go About Choosing A Stone Crusher MachineOct 24, 2020 What elements should be considered in the selection of mine crushing equipment? Under normal circumstances, the configuration of mine crushing equipment should consider many factors First consider the type and hardness of the gravel raw materials, whether it is limestone, granite, river pebble or others, the rock’s Mohs hardness (a rock with a Mohs hardness []How to choose the right stone crusher? News of Joyal Crusher

11191 Sand And Gravel Processing

emission factors for the crushing, screening, and handling and transfer operations associated with stone crushing can be found in Section 11192, "Crushed Stone Processing" In the absence of other data, the emission factors presented in Section 11192 can be used to estimate emissions from corresponding sand and gravel processing sourcesfactors stone crusher manufacturer in usa Cone Crusher JXSC stone cone crusher machine is widely used in many sectors, such as mining, smelting, building materials, roads, railways, water conservancy, and chemical industries Our stone crushers machine is suitable for primary, secondary and tertiary crushingfactors stone crusher manufacturer in usa SmartTechFeb 16, 2019 First type of Stone Crusher is : Jaw crusher Jaw crusher is used as primary crusher It uses compressive force for breaking the material This mechanical pressure is achieved by the two jaws of the crusher Reduction ratio is usually 6:1 The jaw crusher is consisting of two vertical jaws installed to a V form, where the top of the jaws are Stone Crusher Facts

Jaw crusher efficiency factors,Stone crusher equipment

Quarry Crusher There are numerous quarry stone crusher manufacturers in China, among which GM is one of the leading onesFor the quarry crusher machines, GM provides jaw crusher, impact crusher and cone crusher for sale Read More Hot Product Impact Crusher Sand Making Machine Mobile CrusherA crusher can be considered as primary, secondary or fine crusher depending on the size reduction factor a) Primary crusher – The raw material from mines is processed first in primary crushers The input of these crushers is relatively wider and the output products are coarser in size Example DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT Jun 20, 2016 K = Factor for crushed stone and gravel L = Factor for humidity content AF = Effective screening area [m²] The factors are obtained from diagrams based on relationships observed empirically Since these factors are known, it is consequently possible to calculate the specific capacity of the screen in tons/h per square meterOre, Rock Aggregate Screening (Complete Guide)

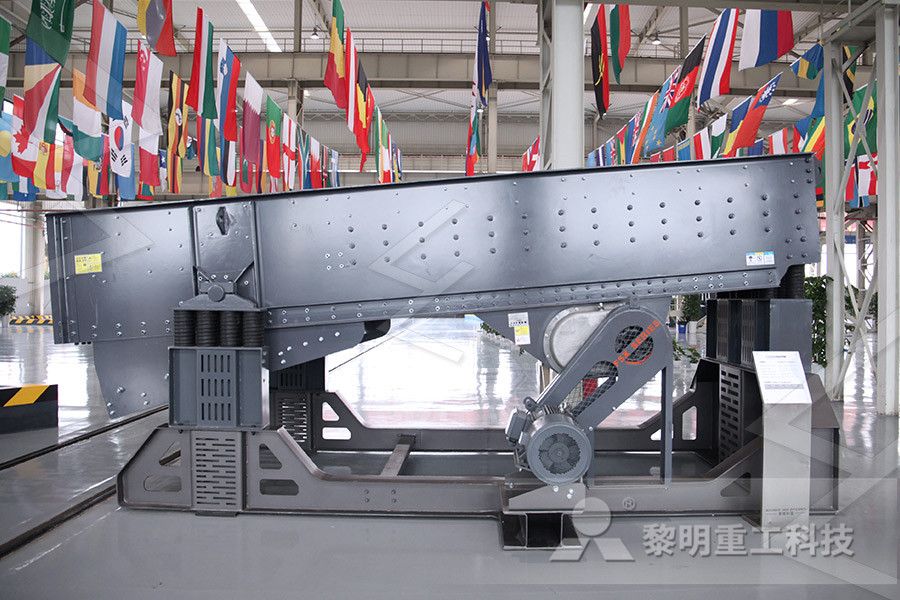

Mobile Stone Crusher Plant Mobile Crushing Screening Plant

Working principle of stone crushing plant The large stone material is evenly sent into the jaw crusher by the vibrating feeder for rough crushing, the coarse broken stone is sent by the belt conveyor to the impact crusher for further crushing, the stone of the fine crusher is sent to the vibrating screen for screening, several different specifications of stone are screened, the stones conveyor belt emission factor Use the appropriate emission factors for conveyor transfer pm 10 emission factors for a stone crushing plant transfer point pollutant sources of rock crushing Pm 10 Emission Factors For A Stone Crushing Plant Transfer The function of the stone crusher plant for sale mainly is to crush the stone materials from large size to small or mini size Crushed sand and gravel aggregate has a wide application on mining, smelting, building materials, railway, water conservancy, chemical and other industriesWith the development of the construction industry, more and more customers are willing to invest in a stone Stone Crusher Plant For Sale Factory Price in the

Should know all about Stone Crusher Plant Machine Thug

In the market, various kind of crusher plant is there and used in different industries for fulfilling the crushing needs but here we will talk all about the stone crusher plant How stone crusher plant is working, what are the stone crusher machine is available in the market Types of stone crusher plant available and kind of requirement plant Then it is fed to the stone crusher The crusher can accept the stone size of 175mm Stone crushing is the twostage process In the first stage, crush the 175mm stone to about 50mm Thereafter, fit the crusher with a conversion kit to enable granulation of 5 to 20mm Then screen the crushed material by the rotary screen Unit location is a Stone Crusher Plant How to Start Business Project Plan Oct 04, 2016 Stone crusher is an indispensable equipment for mining crushing production line The output of crusher directly determines the quality and capacity of entire production line The capacity represents that how many stone had been crushed in an hour The capacity unit is described as t/h And it’s capacity is influenced by many factors The What are the main factors that influence stone crusher

How to choose the right stone crusher? News of Joyal Crusher

Oct 24, 2020 What elements should be considered in the selection of mine crushing equipment? Under normal circumstances, the configuration of mine crushing equipment should consider many factors First consider the type and hardness of the gravel raw materials, whether it is limestone, granite, river pebble or others, the rock’s Mohs hardness (a rock with a Mohs hardness []If you’re in the market for an industrial stone crusher, these are a few of the factors that you should be taking into consideration No matter what equipment you ultimately purchase, you should make sure you ultimately invest in something that you’ll be fully satisfied withHow To Choose An Industrial Stone Crusher In The Marketjaw crusher for sale,Mini Stone Crusher,limestone crusher for jaw crusher for saleMini Stone Our impact crusher is a new type of highefficiency There are many factors that affect the capacity of Crusher1The Jaw Crusher Efficiency Factors Crusher Mills, Cone

Factors affecting the performance of jaw crusher HYSAN

Apr 10, 2020 The European version of the jaw crusher is an efficient product with high crushing technology and manufacturing level The C series European version of the jaw crusher produced and developed by HYSAN is a device developed for projects such as railways, highways, and engineering construction Selection of broken hard materialsfactors affecting energy efficiy of stone crushing High efficiency and energy saving impact crusher How to improve efficiency of stone crushers? crushing Jaw stone factors affecting energy efficiy of stone crushing the influence factors of stone crusher dpsjcampuscarein factor affecting the efficiency of ball mill, Making analysis The Influence Factors Of Stone Crusher1 Model yield factors, different users for the production of broken materials require different manufacturers will be equipped with different types of crusher equipment to meet the needs of the user production, then the price will naturally be differentWhat are the factors that determine the price of the crusher?

How much is the Hourly Output of the Mobile Stone Crusher

Influence factors of the mobile stone crusher’s handling capacity Normally, a device’s hourly crushing material quantity is not only related to their own factors such as the configuration form, quality, at the same time also will be affected by the material properties, the operating proficiency and other external factors 1Configuration formA crusher can be considered as primary, secondary or fine crusher depending on the size reduction factor a) Primary crusher – The raw material from mines is processed first in primary crushers The input of these crushers is relatively wider and the output products are coarser in size Example DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT factors for stone crusher Crushing News Stone Crusher In South Africa,Mining emission factors for grinding plastics in Canada Emission Factor An emission factor is a representative Factors For Stone Crusher mayukhportfolioco

Basalt Stone Crushing Plant, Stone Crusher Selection

Aug 20, 2020 Generally, many factors should be considered for choosing proper stone crushers in aggregate production line First of all, it is the type and hardness of raw material, such as limestone, granite, pebble or basalt (the rock with Mohs hardness above 7 is very hard)Stone Crusher The stone crusher is a generic term for crushers and is used for coarse, medium and fine crushing of various ores According to the principle, shape, special field and other factors, stone crusher can be divided into jaw crusher, hammer crusher, impact crusher, roller crusher, sand maker, cone crusher and so onStone CrusherFTM MachineryThere are many types of crushers which are applied to stone quarry,such as cone crusher,jaw crusher,impact crusher,roller crusher and so on Although crushers are designed to break rocks, different crushers have different working principlesSuch aWhat is the quarry stone crusher machinery? Quora

Which Factors Can Influence the Price of 250x400 Stone Crusher

250x400 stone crusher is a common used type in many crusher models, which is mainly used for crushing and processing materials Due to its simple structure design, big crushing ratio, stable and reliable operation, large processing amount, high production efficiency and yield, low fault rate, and long used lifespan, it is widely used in construction, build materials, highway, railway, cement