Compare Gyratory Crusher vs Jaw Crusher 911 Metallurgist

Jaw and gyratory crushers are heavy equipment and are not used extensively in the food industry In a jaw crusher, the material is fed in between two heavy jaws, one fixed and the other reciprocating, so as to work the material down into a narrower and narrower space, crushing The first above ground gyratory jaw crusher to be installed in Australia is based on thyssenkrupp’s proven BK 6375 design A customised gyratory jaw crusher solution is adding extra ‘teeth’ to a Western Australian extractive operationGyratory jaw crusher – with an edge – Quarry The gyratory crusher is mainly used for coarse crushing of various hard material in the primary crushing stage, but it is not suitable for crushing viscous ore Jaw crusher can crush high moisture, viscous ore, and not easily blockedJaw Crusher VS Gyratory Crusher JXACHINE

Gyratory Crusher an overview ScienceDirect Topics

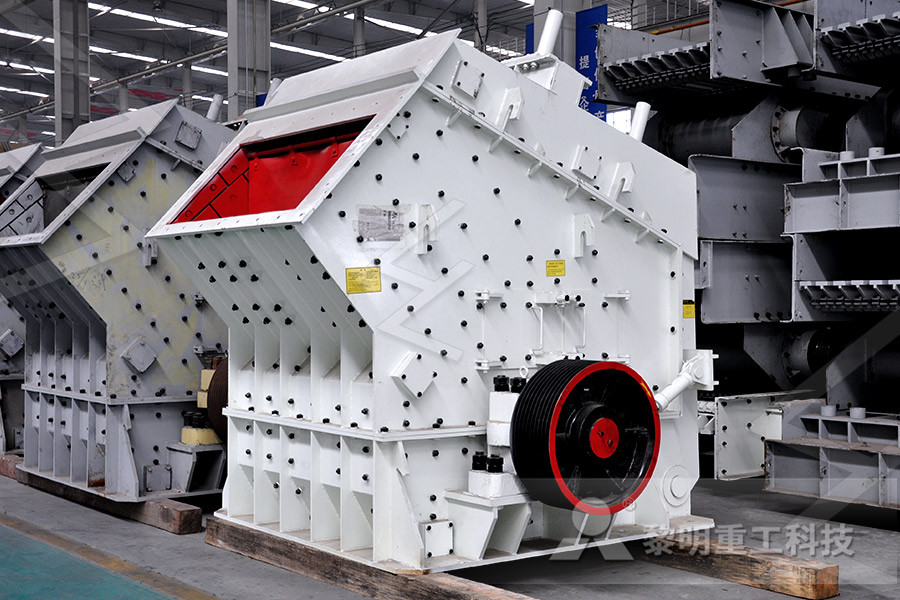

Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact Jaw gyratory crushers – design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only It is normally serrated and, to gether with the upper part of the mantle, it forms the initial crushing zone TheIndustrial Solutions Gyratory crushers “The jaw gyratory crusher is characterised by an especially large feed opening,” Suda says “It is normally serrated out and, together with the upper part of the mantle, forms the initial crushing zone “The coarsely crushed material is then reduced to the desired product size in the crushing thyssenkrupp extends gyratory crusher winning streak

Crushers Gyratory and Jaw Holdtrade (UK) Ltd site

Gyratory Crusher Gyratory crushers are primary crushers that receive blasted material from the mine or quarry Similar to jaw crushers they work by grinding the material between two surfaces Jaw crushers Traylor and FullerTraylor gyratory crushers of the early 1900s crushers have continuously withstood the harshest requirements found in the world’s mines and rock quarries Through constant and continual improvements in engineering to meet customer needs, is a provenCrushing Systems The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience thyssenkrupp gyratory crushers represent today‘s stateoftheart They are designed for high throughput rates and high crushing ratios at low operating and maintenance costs Pro Design characteristics Maintenance friendly designGyratory crusher manufactor thyssenkrupp

Industrial Solutions Gyratory crushers

Jaw gyratory crushers – design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only It is normally serrated and, to gether with the upper part of the mantle, it forms the initial crushing zone The Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter and feature a higher crushing ratio, thyssenkrupp extends gyratory crusher winning streak Jaw crushers Traylor and FullerTraylor gyratory crushers of the early 1900s crushers have continuously withstood the harshest requirements found in the world’s mines and rock quarries Through constant and continual improvements in engineering to meet customer needs, is a provenCrushing Systems

Cone Crusher VS Gyratory Crusher JXSC Mine

2 天前 Jaw Crusher VS Gyratory Crusher Performance Different 1 The rotating speed of the movable cone of the gyratory crusher is low, the stroke is small And the ore is mainly crushed and broken and bent The cone crusher has 25 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quicklyHazemag Gyratory Crushers, Jaw Crushers, and Cone Crushers Hazemag compressive crushing products are ideal for the processing of the most difficult materials in both the aggregate and mining sectors, fulfilling a wide range of application needsCrushing – Hazemag North America Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1 Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1 The primary operating variable available on a crusher is the set and on jaw and gyratory the openside set (OSS) is specified This reflects the fact thatTECHNICAL NOTES 5 CRUSHERS Mineral Tech

Jaw crusher SlideShare

• Types Of Crushers • Jaw crushers • Gyratory crushers • Difference • Difference between these jaw crushers is the feed rate and product rate and design, we are, however, going to talk about jaw crushers in this particular presentation 5 • Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particle Gyratory crushers generally cost less than $1500 per hour to run, while Jaw crushers cost less than $200, including electricity (Infomine, 2008) Rules of Thumb • A 42inch gyratory crusher produces approximately 24 tons per horsepowerhour (29 t/kWh)Crushers QueensMineDesignWikiCMS Cepcor® The difference since 1960 CMS Cepcor® have supplied hundreds of new, factory reconditioned, refurbished and used jaw crushers, cone crushers, impactors, screens and feeders to mining and aggregate processing; establishing a worldwide reputation for the supply of quality crushing and screening plant We are experts in the rebuilding of crushers, screens and feeders originally Crusherscouk New Used crushers, screens

doublemouth jawgyratory crusher Archives

The company explained: “This unique jawgyratory crusher is a modern machine based on the proven BK 6375 design thyssenkrupp has developed a new, patented, spider to give the opportunity to feed the crusher from both sides – the “double mouth” jaw configuration, thus removing the need for a primary crusher feed (buffer) hopper and C6X Series Jaw Crusher The C6X Series Jaw Crushers is mainly used in many different industrial fields such as metallurgy, nonmetal ores, chemical, cement, crusher gyratory vs jaw crusherGyratory Crusher an overview ScienceDirect Topics The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavescrushers jaw crusher and gyratory crusher

Roy Hill buys jaw gyratory crusher from thyssenkrupp

Jaw gyratory crushers have enlarged feed openings that are usually serrated which, along with the upper part of the mantle, forms the initial crushing zone Coarsely crushed material is then reduced to the desired product size in the crushing chamber below Related stories:Product Our products cover crushers, grinding mills, screens, feeders, classifiers, conveyor belts and others Core products include GC gyratory crushers, JC jaw crushers, CC hydraulic cone crushers, MC hydraulic cone crushers, HS impact crushers, VS verticalshaft impact crushers, YKR/ZKR vibrating screens, HPF grizzly feeders, MP/MK mobile crushing screening plants, and CLTC drywet dust GC gyratory crusher nmsindustries2 天前 Jaw Crusher VS Gyratory Crusher Performance Different 1 The rotating speed of the movable cone of the gyratory crusher is low, the stroke is small And the ore is mainly crushed and broken and bent The cone crusher has 25 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quicklyCone Crusher VS Gyratory Crusher JXSC Mine

Crushers an overview ScienceDirect Topics

Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact Jaw crushers Traylor and FullerTraylor gyratory crushers of the early 1900s crushers have continuously withstood the harshest requirements found in the world’s mines and rock quarries Through constant and continual improvements in engineering to meet customer needs, is a provenCrushing Systems • Types Of Crushers • Jaw crushers • Gyratory crushers • Difference • Difference between these jaw crushers is the feed rate and product rate and design, we are, however, going to talk about jaw crushers in this particular presentation 5 • Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particleJaw crusher SlideShare

New, used rebuilt jaw crushers

svedala superior® gyratory; bergeaud; flsmidth; hp® series; gp® series; c lt series; cms cepcor; css std shd; gyratory; mp® series; skako® goodwin barsby™ ® jw series; hazemag; kueken double toggle; parker plant; brown lenox kueken st;