economy rolling mill with 7 rolls LMMGROUP

We manufacture various highquality rolling rolls according to the clients' needs , and to ensure the stability and accountability of the quality Skip to content 86 411 Building 8, Yintian South Park, Yida Chuntian, Ganjingzi District, Dalian , ChinaDetails This made in India rolling mill is perfect for the hobbyist or student who needs a rolling mill but doesn’t want to spend a lot of money The roll size is 76mm (3”) wide, by 43mm diameter The rolls are manufactured from selected high carbon steelIt is a light duty mill, and just like any other jewelers rolling millBlue Economy Rolling Mill with 7 Rolls OttoFreiHere we have our new budget mini rolling mill with 7 rolls complete with 2 plain, 2 wire, 1 V shaped and half round and fancy rolls As with all rolling mills they are for use with non ferrous metals A rolling mill is a tool used to apply pressure to metal to flatten and lengthen it A rolling mill is often used to press an ingot ( a block of Proops Budget Jewllers Mini Rolling Mill with 7 Rolls

Amazon: 3" (80mm) Rolling Mill Machine with 7

3" (80 mm) Rolling Mill Machine with 7 Metal Roller Jewelry Tools Flat, Pattern, Wire Accessories: 1 Rolling Mill Machine (2 rollers assembled), 5 Extra Metal Roller, 1 Handle, 1 Roller Adjustment Screw The Rolling Mill Machine is designed to meet the needs of Jewelers and metal smith It is compact, economical, and cost effectiveIndian Rolling Mill 75mm Rolls available direct from Blue Sky Components Limited 7 in 1 Mini Rolling Mill (7 roll model, not 5) Receive extra with this model at a unbeatable price remarkable value and an outstanding buildJewellers Mini Rolling Mill with 7 Rolls 3" x 1 5/8 Select from three different models for a variety of shapes according to your need Rolls are 167” in diameter and 3” in length Combination Economy Rolling Mill [Flat with extra rollers textured and 1/2 round] $32000 35021: Flat Wire Combination Economy Rolling Mill: $32000 35019: Flat Economy Rolling MillEconomy Rolling Mills American Jewelry Supply

Silver Economy Rolling MillFlat Rolls Only

Because it uses the same rolls as our other economy rolling mills, (76mm x 43mm), you can choose from a wide selection of optional wire and pattern rolls to customize the Super Economy mill We have matched upper and lower wire rolls for making wire reductions, and various upper wire and pattern rolls for making finished wire and strip 7 Rollers: 2 Flat Rollers, 2 Patterns Rollers and 3 Wires (Rollers 075 to 5mm) PLEASE NOTE: Round wire cannot be formed on a rolling mill The 3 wire rolls included with this rolling mill will form wire that is roughly square in profile with 4 cut corners This wire is ECONOMY ROLLING MILL With 5 Rollers Economy Jewelers use Economy Rolling Mill A rolling mill for a price that cannot be matched or beat Suitable for the small shop Has 4:1 gears and a set of extra rollers for Rolling mill eco w/5 rolls jewelerstoystore

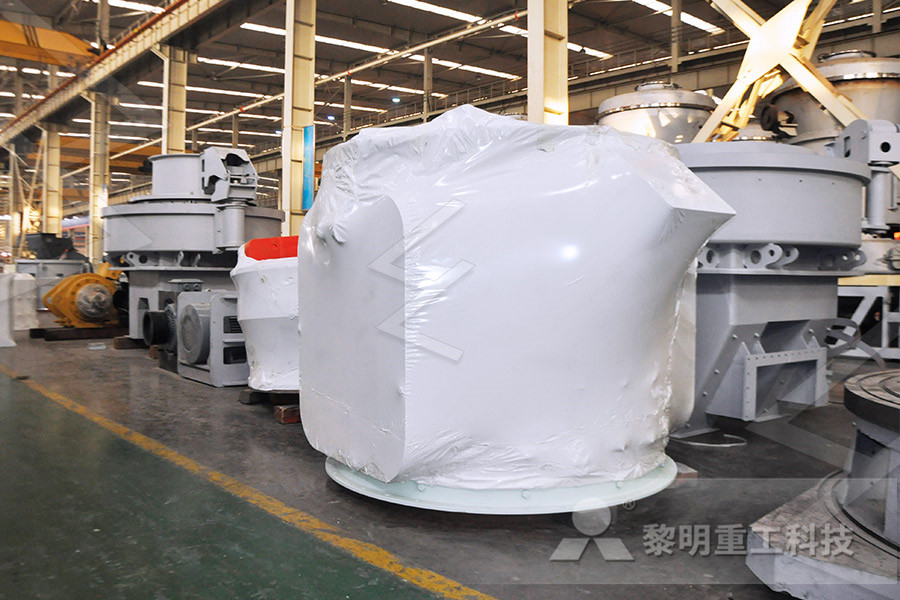

ROLL GRINDERS AND AUTOMATIC ROLL SHOPS

Work rolls, intermediate rolls, backup rings Ø max 450mm Cold Hot Mill Work and intermediate rolls Ø max 800mm With and without chocks Cold Hot Mill Work, intermediate and backup rolls Ø max 1800mm With and without chocks Plate Hot Mill Work rolls, backup rolls Ø max 2400mm + With and without chocks Paper Mill, Roll Makers,The Rolling Mill Machine is designed to meet the needs of Jewelers and metal smith It is compact, economical, and cost effective Rollers are hardened approx 60 HRC for superior deformation resistance For mounting 2 bolting holes are provided in the base of rolling mill It is great solution with diffrent variants of roller designsAmazon: 3" (80mm) Rolling Mill Machine with 7 Mini Rolling Mill With 5 Rolls Of Size 3" X 15/8" Supplied With High Quality SS Gears Wheels (2 Plain, 1 V Shape Half Round And 2 Fancy Rolls) GS 643: Mini Rolling Mill With 7 Rolls Of Size 3" X 15/8" Supplied With High Quality SS Gears Wheels (2 Plain, 2 Wire, 1 V Shape Half Round And 2 Fancy Rolls)Rolling Mills Rolls Mini Rolling Mill Pattern Rolls

PATTERN ROLL For Economy Rolling Mills From

This high quality manufactured and durable pattern rolls are designed with the best material for used with our economy rolling mills They are installed in upper position when standard flat roll is in the lower position great for creating textures on bangles, bracelets wires Wide pattern from 07 to 3 bination Rolling Mill For Making Round Sheet Stock This is a new combination rolling mill with 5 rollers This is a well made rolling mill used for rolling out silver, gold, etc into wire or sheet Rollers are fabricated from selected high carbon steelAmazon: Rolling Mill Jewelers High Grade Tool 5 Although the extension flat rollers are a great addition, still, the Durston Mini C80 rolling mill has 80mm rolls with a diameter of 45mm As a comparison, both Pepetools combination rolling mills reviewed here come with 90mm and 160mm rolls, respectively So, this model offers the smallest surface area for sheet rolling, which can be a problem Best Rolling Mill For Jewelry (2020 Reviews): Our

Rolling Mill Pattern Roller (2 piece min)

This patterned wire roller will fit in both of our economy rolling mills (product number 28282, 28281, or 28280), and can be used on various gauges of soft metals Not for use on hard metals This roller imitates various types of wire such as beaded, braided, twisted, Florentine, diamond cut or others ranging in size from 06 to 4 millimeter THE ROLLING MILL The rolling mill is a machine designed to produce thinner gauges of sheet metal and wire Most studio jewellers use a hand cranked mill (although automated mills are used as well) Each mill consists of two smooth, highly polished, hardened steel rolls, mounted in the housing parallel to each other The rolling mill us used for Instructions for Usage Maintenance SafetyPrimetals Technologies has developed a new Universal CrownControl Mill (HYPER UCM) that features work rolls with diameters that are 20% to 40% smaller than those used in conventional UCM mills This allows greater thickness reductions to be achieved in the coldrolling process, which is particularly important for the rolling of advanced high NEXTGENERATION ROLLING MILL STAND Primetals

Potter USA Fine Tools Rolling Mill Plates

This plate is designed to be used in a rolling mill with annealed, nonferrous metal late Size: ~7" L x 2" W Plate Thickness: ~25mm Design Size: 11/8" W x 5" L Add to cart Skeleton Leaves 1 RMP018This mill can use the lateral shifting of the intermediate rolls in the work roll bending technology used With these, we can effectively reduce the edge drop phenomenon, so flatness accuracy has been greatly improved, but also can reduce the bending force of the work rolls, and finally to the finished product quality has been greatly improved薄板六辊可逆轧机——辊系设计毕业设计图文百度文库The Rolling Mill Machine is designed to meet the needs of Jewelers and metal smith It is compact, economical, and cost effective Rollers are hardened approx 60 HRC for superior deformation resistance For mounting 2 bolting holes are provided in the base of rolling mill It is great solution with diffrent variants of roller designsAmazon: 3" (80mm) Rolling Mill Machine with 7

ROLLING Mill Jeweller JEWELLERY Manual Roll

This is an Economy/Budget rolling mill, for high quality rolling mill, please see our listing Quality ROLLING Mill Jewellers Jewellery Manual Roll Machine 130mm You are buying 1 jewellers manual rolling mill made by one of the largest OEM factory in the world Solid build, perfect workmanship, simple and reliable operation R olls are hardened to 60 HRC For making jewellery wires and Combination Rolling Mill For Making Round Sheet Stock This is a new combination rolling mill with 5 rollers This is a well made rolling mill used for rolling out silver, gold, etc into wire or sheet Rollers are fabricated from selected high carbon steelAmazon: Rolling Mill Jewelers High Grade Tool 5 Primetals Technologies has developed a new Universal CrownControl Mill (HYPER UCM) that features work rolls with diameters that are 20% to 40% smaller than those used in conventional UCM mills This allows greater thickness reductions to be achieved in the coldrolling process, which is particularly important for the rolling of advanced high NEXTGENERATION ROLLING MILL STAND Primetals

Instructions for Usage Maintenance Safety

THE ROLLING MILL The rolling mill is a machine designed to produce thinner gauges of sheet metal and wire Most studio jewellers use a hand cranked mill (although automated mills are used as well) Each mill consists of two smooth, highly polished, hardened steel rolls, mounted in the housing parallel to each other The rolling mill us used for Lacy West Supplies, Ltd PEPE 110mm Combination Rolling Mill [P18820A] PEPE 110mm Combination Ultra Rolling MillGear ratio 4:1 Roller width 110mm Roller diameter 55mm Maximum opening 5mm Flat area (+/ 001mm) 57mm Square wire (+/ 001mm) : 10, 20, 30, 40 Ring shank half round ellipsis: 25 x 1:3 x 125 ; 4 x 15 Capable of producing metal foil as thin asPEPE 110mm Combination Rolling Mill [P18820A] Lacy West Supplies, Ltd PEPE Ultra 130mm Combination Rolling Mill [P18920A] PEPE Ultra 130mm Combination Rolling MillGear ratio 4:1 Roller width 130mm Roller diameter 65mm Maximum opening 5mm Flat area (+/ 001mm) 130mm Square wire (+/ 001mm) : 10, 20, 30, 40 , 45, 50, 55, 60, 65 Ring shank half round ellipsis: 25 x 1:3 x 125 ; 4 x 15 Capable of producingPEPE Ultra 130mm Combination Rolling Mill [P18920A

IMPORTANT!

3 Keep the rolls clean Do not touch the rolls Oils and acids from your body can damage the rolls, leaving behind small marks and eventually rust 4 Make sure all material is dry before rolling 5 Do not use your mill with the rolls completely closed 6 Do not roll ferrous metals such as iron or steel through the mill 7 the work rolls and these may be amplified by natural resonances of the rolling mill These natural resonances are typically between 500 and 1000 Hz and are often referred to as the 5th octave resonances of the mill In this case, the forced vibration had Quality Improvement in Finished Cold RolledThis mill can use the lateral shifting of the intermediate rolls in the work roll bending technology used With these, we can effectively reduce the edge drop phenomenon, so flatness accuracy has been greatly improved, but also can reduce the bending force of the work rolls, and finally to the finished product quality has been greatly improved薄板六辊可逆轧机——辊系设计毕业设计图文百度文库