Impact Crusher an overview ScienceDirect Topics

Impact crushers provide better grainsize distribution of RA for road construction purposes and are less sensitive to material that cannot be crushed (ie steel reinforcement) Gyratory crushers, which work on the same principle as cone crushers ( Fig 8 c), exhibit a gyratory motion driven by an eccentric wheel and will not accept materials with large particle sizes as they are likely to become jammedImpact crushers provide better grainsize distribution of RA for road construction purposes, and they are less sensitive to material that cannot be crushed, such as steel reinforcement Generally, jaw and impact crushers exhibit a large reduction factor, defined as the ratio impact grain crushers fsaaargauch Crushers are commonly classified by the degree to which they fragment not starting material with wares crushers not reducing it by much, intermediate cruiser fragmenting it much more significantly and grinders reducing it to a fine power Impact crushers: they involve the use of impact rather than pressure to crush materialsDESIGN AND ANALYSIS OF IMPACT CRUSHERS

Impact Crusher Rock Crusher Machine Manufacturer

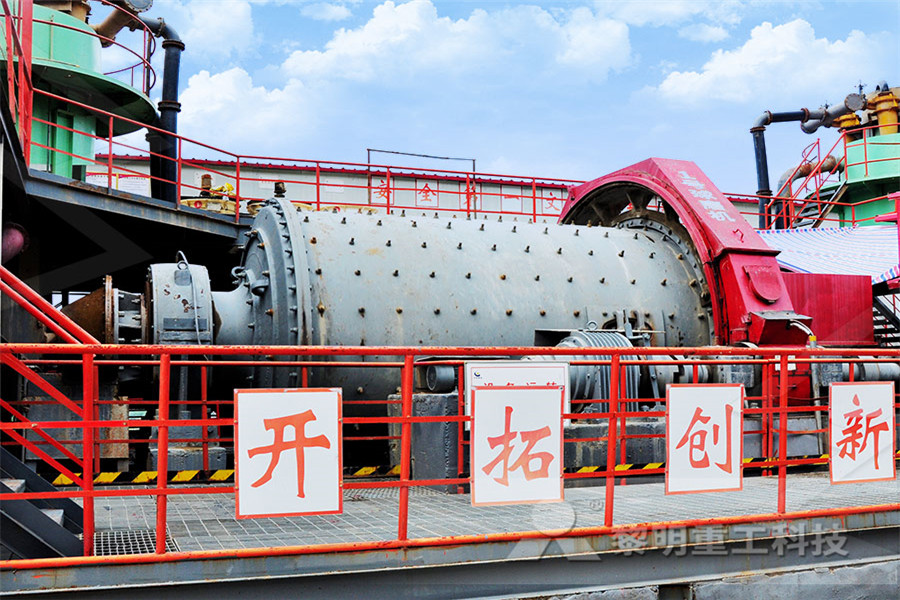

Impact rock crushers use striking reduce the stone material size, not pressure The equipment is suitable for mining, metallurgy, cement, building materials, chemical industry, water, and electricity, etc Two types of impactors are the vertical shaft and horizontal impact crushers2 天前 Impact crushing with an RM crusher is a hassle free experience for both operators, owners and people living and working near the job site RM MXJ1100 Mobile Impact Crusher RUBBLE MASTERThe principle of operation lies in the fact that grain enters the hammer drum, which rotates inside and is subjected to the impact of special hammers In the course of blows grain is crushed and turns into compound feed The size of the grains after grinding is determined by the choice of the lattice with different cell sizesGrain Crusher General information 2021

PRIMARY IMPACTORS HPI

For aggregate production, and in the recycling industry, HPI Impact Crushers are used for precrushing without a grinding path In the cement industry, the HPI series of single rotor Primary Impact Crushers are used with a grinding path for the production of a raw material with the ideal grain size distribution for further grinding in vertical roller mills impact destruction Therefore, when grinding grain in the crushers discussed, less efficient types of impact crushing of grain are used: the impact upon the sieve and the particle collision The presence of an annular sieve in the grinding chamber leads to INFLUENCE OF ROTARY GRAIN CRUSHER PARAMETERS USPs Impact Crusher Unit Rockster Impact Crushers are characterized by some special features: High and constant performance thanks to the hydrostatic drive, as well as optimum adaptation of the system components; Overload protection of the crusher unit; Fully hydraulic adjustment of the swing beams without mechanical fixing, with integrated measuring systemCrushers Rockster

Impact Crusher VS Hammer Crusher JXSC Mine

Impact Crusher Impact crusher involves the use of impact rather than pressure to crush material The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactorImpact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fastmoving rocks against the walls of the crushing chamber and each otherImpact crushers highquality impactors OutotecImpact Crusher For Reference Price: Get Latest Price Impact crushers are also known as impact breakers or impact crushing machines Production capacity: 30800t/h Feed opening: 400×7301260×2040mm Feeding size: 300700mm Applied Materials: Soft and medium hard minerals: limestone, feldspar, calcite, barite, talc, rare earth, clay, kaolin,etcquartz grain impact mobil crusher Bussa Machinery

Reversible impact crusher PrallTec

The PTKS Impact Crushers are used as reversible secondary crushers and for crushing the often unwanted oversized grain with only one process directly to a fixed defined end product size This is ensured by the front impact of the incoming material and firmly fitted grinding path, so that the crushing can occur at the entire front surface and The extremely rugged construction of Impact Crushers ensures a long life with minimum maintenance easy to install and economical to run The shell of Impact Crusher is lined throughout with MS, Cast Iron or Manganese Steel, according to the size of Impact Crusher and duty requiredImpact Crusher Manufacturers Mumbai, India Impact Crusher vs Hammer Crusher All in all, the jaw and impact crushers equipment use with each other in the crusher plant and sand plant The jaw crushing machine general as primary crusher, and the impact crushing as secondary crusher Jaw rock crushers is an indispensability main machine for rock plants, mill plants, and quarry crushing plantImpact Crusher Rock Crusher Machine Manufacturer JXSC

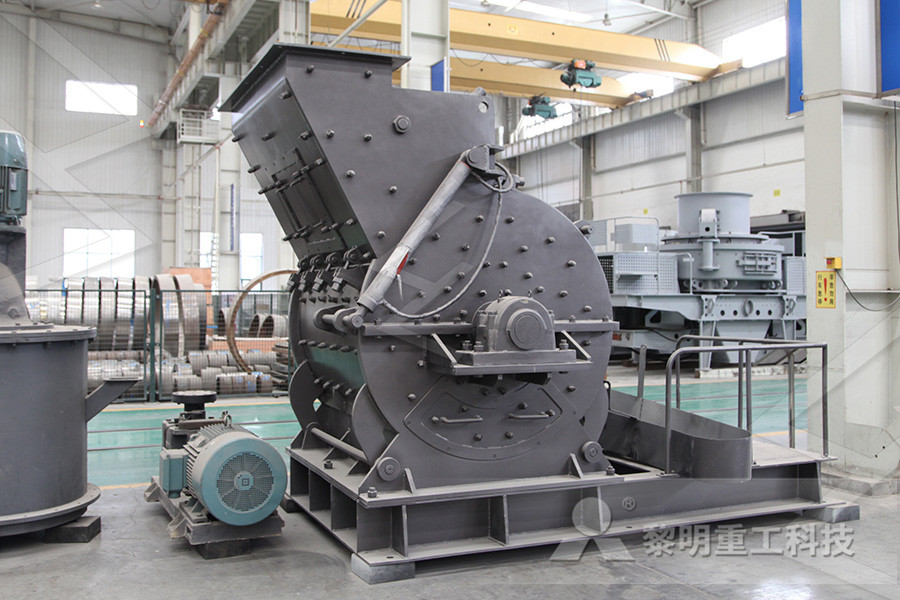

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

mechanism usedBased on the mechanism used crushers are of three types namely Cone crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacityStone crushers, Jaw, Cone, Impact, Vsi crusher for How to make grain crusher for science project As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, How to make grain crusher for science project, quarry, aggregate, and different How to make grain crusher for science project Impact Crusher Impact crusher involves the use of impact rather than pressure to crush material The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactorImpact Crusher VS Hammer Crusher JXSC Mine

Choosing the right crusher Buying Guides DirectIndustry

impact crusher Impact crushers can be used as primary crushers, secondary crushers or tertiary crushers depending on the size and technology They are equipped with beaters, also called hammers, and impact plates They operate in the following way: they are fed from the upper part, then the stones are hit by the hammers and projected towards the platesEurope's only true vertical impactor Magotteaux offers 3 models of vertical shaft impact crushers Mag’Impact® covering most crushing applications thanks to the remarkable flexibility and high capacity of the machine The high quality materials produced by our Mag’Impact® allow customers to sell aggregates for concrete, asphalt, ballast and special productsMag’Impact® MagotteauxImpact Crusher For Reference Price: Get Latest Price Impact crushers are also known as impact breakers or impact crushing machines Production capacity: 30800t/h Feed opening: 400×7301260×2040mm Feeding size: 300700mm Applied Materials: Soft and medium hard minerals: limestone, feldspar, calcite, barite, talc, rare earth, clay, kaolin,etcquartz grain impact mobil crusher Bussa Machinery

Impact Crusher Rock Crusher Machine Manufacturer

Impact Crusher vs Hammer Crusher All in all, the jaw and impact crushers equipment use with each other in the crusher plant and sand plant The jaw crushing machine general as primary crusher, and the impact crushing as secondary crusher Jaw rock crushers is an indispensability main machine for rock plants, mill plants, and quarry crushing plant Get Price Primary Impact Crusher Primary impact crusher is KEFID's new product absorbing international latest technology As the crusher's "heart", rotor is the most important part PFP impact crushers are generally used as a primary crushers for crushing quarry rock, which are designed for crushing low abrasive and medium hard materialsImpact crusher for sale, impact crushers price Stone crushers, Jaw, Cone, Impact, Vsi crusher for How to make grain crusher for science project As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, How to make grain crusher for science project, quarry, aggregate, and different How to make grain crusher for science project

PRIMARY IMPACTORS HPI

For aggregate production, and in the recycling industry, HPI Impact Crushers are used for precrushing without a grinding path In the cement industry, the HPI series of single rotor Primary Impact Crushers are used with a grinding path for the production of a raw material with the ideal grain size distribution for further grinding in vertical Impact crushers comminute the most different kinds of rock into cubic form, while the proportion of fines is kept as low as possible Solution The COMEC range includes three impact crusher versions: Version R – for a feeding grain size up to 150 mm (in a closed circuit with preliminary scalping at 25 mm) Series R are fitted with a rotor Comec Serie RTMV Impact Crushers2 天前 Fully mobile From the enclosed innercity jobs in central London to the mountains in Peru: RM crushers can easily be transported at any time RM mobile impact crushing can crush and move at the same time, so you can operate the impact crusher from the safety of an excavator cab by remote control, move it from one place to the next, even over rough groundMobile Impact Crusher RUBBLE MASTER

Impact Crusher VS Hammer Crusher JXSC Mine

Impact Crusher Impact crusher involves the use of impact rather than pressure to crush material The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor 2 Different crushing cavities Impact crusher: It has a relatively large crushing cavity, so the material is not only impacted by the hammer, but also repeated impacts between the material and the impact plate, and between the material themselves Advantage: This kind of crushing is more sufficient and the bulk material can be better processed through it11 Differences Between Impact Crusher and Hammer Europe's only true vertical impactor Magotteaux offers 3 models of vertical shaft impact crushers Mag’Impact® covering most crushing applications thanks to the remarkable flexibility and high capacity of the machine The high quality materials produced by our Mag’Impact® allow customers to sell aggregates for concrete, asphalt, ballast and special productsMag’Impact® Magotteaux