Operating Costs of Gold Processing Plant 911

Operating Costs of Gold Processing Plant Post navigation Previous Next A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be ‘obtained when handling a low grade ore by a simple process Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design The magnetic extraction process of manganese mineral can be applied to separate high phosphate ore, highsilicon ore and low bixbyite ore Tailings ReProcessing Line Xinhai tailings reprocessing line applies to reprocessing of various metal or nonmetal tailings, including iron, gold, leadzinc, copper, fluorite, wolfram, phosphate, graphite gold ore processing cost

What is the Cost of Mining Gold? Visual Capitalist

How Top Gold Mining Stocks Performed in 2020 Gold mining stocks and the GDX saw strong returns in 2020 as gold was one of the most resilient and best performing assets in a highly volatile year But picking gold These numbers report that the cost of extracting an ounce of gold is actually over $1,000 per ounce, well above the aforementioned numbers And since gold is The true cost of producing an ounce of gold Provident Processing, smelting and refining gold With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitatorsProcessing, smelting and refining gold World Gold

Gold Processing Methods Gold Ore Extraction

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration Tests that mirror each of In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the mineralogy in order to optimise flowsheet selection and cost drivers, and get the best out of the process An ore Gold processing 101 Mining Magazine The processing plant will be designed with two distinct operating mode The mode used s will depend on the ore being treated Oxide ore with a low copper content will be treated at a nominal throughput of , t/year through a hybrid carboninleach (CIL) plant to recover gold as bullionAPPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE

What is Gold Ore worth? High Grade Mining Ore

Ore is defined as “a naturally occurring mineral containing a valuable constituent (as metal) for which it is mined and worked” In other word, ore is the most basic raw form of a mineral, which requires additional processing for the valuable minerals (gold) to be removed A single piece of gold ore generally has very little actual gold cost of processing gold ore in dominican rep Gold refining gold mines process ore using various techniques to produce an alloy composed primarily of gold and silver, which is called a dore bar the composition of dore can vary significantly between mines, but generally the gold dore bars the perth mint processes are composed of between gold cost of processing gold ore in dominican rep The roasting cost works out at approximately $122 per ton of concentrate, distributed as shown in Table 99 At MacLeod Cockshutt Gold Mines, Ltd, the cost of roasting in 1941 1942 was 32 cents per ton milled or $125 per ton of ore roasted, while at Lake Shore mines for the same year the cost was about 80 cents per ton roastedMineral Processing Operating Cost Estimate of Ore Treatment

gold ore processing cost

The magnetic extraction process of manganese mineral can be applied to separate high phosphate ore, highsilicon ore and low bixbyite ore Tailings ReProcessing Line Xinhai tailings reprocessing line applies to reprocessing of various metal or nonmetal tailings, including iron, gold, leadzinc, copper, fluorite, wolfram, phosphate, graphite How Top Gold Mining Stocks Performed in 2020 Gold mining stocks and the GDX saw strong returns in 2020 as gold was one of the most resilient and best performing assets in a highly volatile year But picking gold mining stocks isn’t easy, as each company has a variety of individual projects and risks worth assessingWhat is the Cost of Mining Gold? Visual Capitalist In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the mineralogy in order to optimise flowsheet selection and cost drivers, and get the best out of the process An ore containing 1% sulphur will produce a mass pull of approximately 5% by Gold processing 101 Mining Magazine

150t/d Gold Ore in Tanzania Cost Analysis of Gravity

1 Costbenefit Analysis It’s advisable that the ore veins of Tanzania NHM Company adopt the wastelifting stoping mining methods The ore bodies of different thicknesses have many similarities in the technology of wastelifting stoping; and the labor and material costs that every mining cycle consumes are basically the same Tietto Minerals is zeroing in on a lowcost ore processing flow sheet at its 22Moz Abujar gold project in Côte d’Ivoire in West Africa, with a simple, lowenergy crushing, grinding and cyanide leaching circuit looking to be achievable, according to the ASXlisted companyTietto zeros in on lowcost gold processing in Africa Purchase Advances in Gold Ore Processing, Volume 15 1st Edition Print Book EBook ISBN 02, 80Advances in Gold Ore Processing, Volume 15 1st Edition

Resources Reserves – Fiore Gold Ltd

Pitconstrained resource based on an assumed gold price of US$1,700/oz, Silicic (hard) ore recoveries of 60% for Au and an Argillic (soft) ore recovery of 80% for Au, an ore mining cost of US$209/st, a waste mining cost of $197/st, an ore processing and GA cost of US$313/st, and pit slopes between 4550 degrees; Resources are reported using Technological advances have taken biooxidation from a concept to commercial reality The understanding and funding of bench, pilot, and fullscale programs is steadily increasing Today, biooxidation technology is successful in a range of conditions, from ideal to the most severe climates in the world Because of this flexibility, biooxidation can be effectively integrated into goldprocessing The bioleaching and processing of refractory gold ore These numbers report that the cost of extracting an ounce of gold is actually over $1,000 per ounce, well above the aforementioned numbers And since gold is currently trading at just over $1,200 per ounce, it explains why mining companies have had lessthanstellar profitsThe true cost of producing an ounce of gold Provident

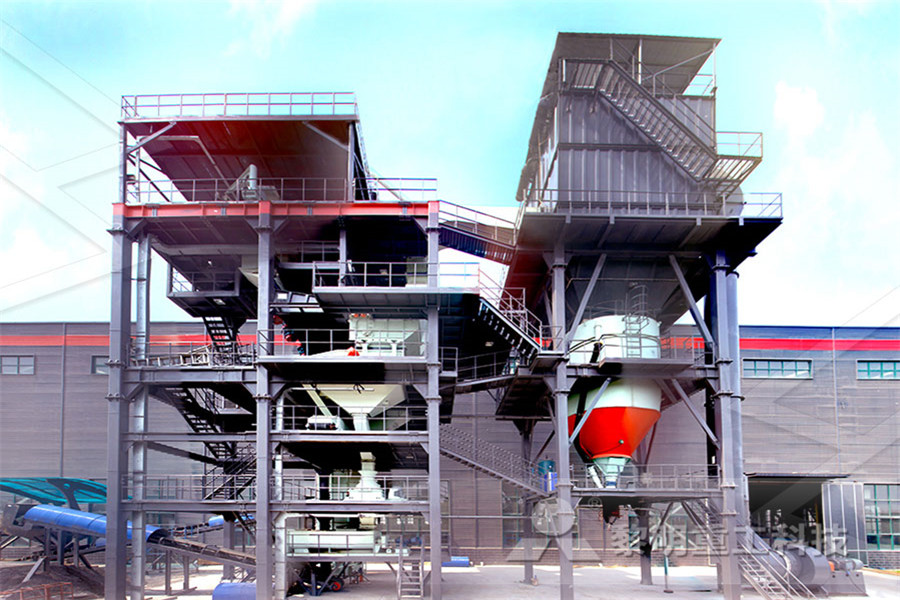

cost of benfiion plant for gold ore saffronfresh

Gold Processing Plants and Complete Ore Process Plant Actual cost will vary depending of the process details and detailed equipment list and origin Please use this In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the mineralogy in order to optimise flowsheet selection and cost drivers, and get the best out of the process An ore containing 1% sulphur will produce a mass pull of approximately 5% by Gold processing 101 Mining Magazine For example a mine that is processing 100,000 ounces but failing to capture 5 to 10% of its gold due to solution loss, is at current gold prices losing $10 million to $12 million in revenueCostsaving nanotechnology set to disrupt gold processing

150t/d Gold Ore in Tanzania Cost Analysis of Gravity

1 Costbenefit Analysis It’s advisable that the ore veins of Tanzania NHM Company adopt the wastelifting stoping mining methods The ore bodies of different thicknesses have many similarities in the technology of wastelifting stoping; and the labor and material costs that every mining cycle consumes are basically the same WHAT’S HAPPENING IN GOLD ORE PROCESSING? April 2019 Factors driving new developments in gold technology include increasing environmental concern and government regulation over the use of cyanide, the trend towards refractory, complex, and lower grade resources, and the pressure to reduce operating cost and increase plant performance efficiencyALTA MetBytes What's Happening in Gold Ore Processing the refractory Fosterville gold ore Kirkland Lake Gold is a midtier gold producer targeting ~530,000 – 570,000 ounces in Tier 1 mining jurisdictions of Canada and Australia The production profile of the Company is anchored by three highgrade, lowcost operations, the ROBUST, LOWCOST BIOX PROCESS AT FOSTERVILLE

Gold Ore Processing, 2e Contributors Support World Gold

Markus has contributed a new chapter to Gold Ore Processing, 2e, entitled “Gold – a Key Enabler of a Circular Economy: Recycling of WEEE” Understandably, in the current resource priceconstrained environment, there was much highlevel discussion on capital intensity, cost reduction, and productivity innovations in new technologiesOre is defined as “a naturally occurring mineral containing a valuable constituent (as metal) for which it is mined and worked” In other word, ore is the most basic raw form of a mineral, which requires additional processing for the valuable minerals (gold) to be removed A single piece of gold ore generally has very little actual gold What is Gold Ore worth? High Grade Mining Ore Purchase Advances in Gold Ore Processing, Volume 15 1st Edition Print Book EBook ISBN 02, 80Advances in Gold Ore Processing, Volume 15 1st Edition