Factors Affecting Ball Mill Grinding Efficiency

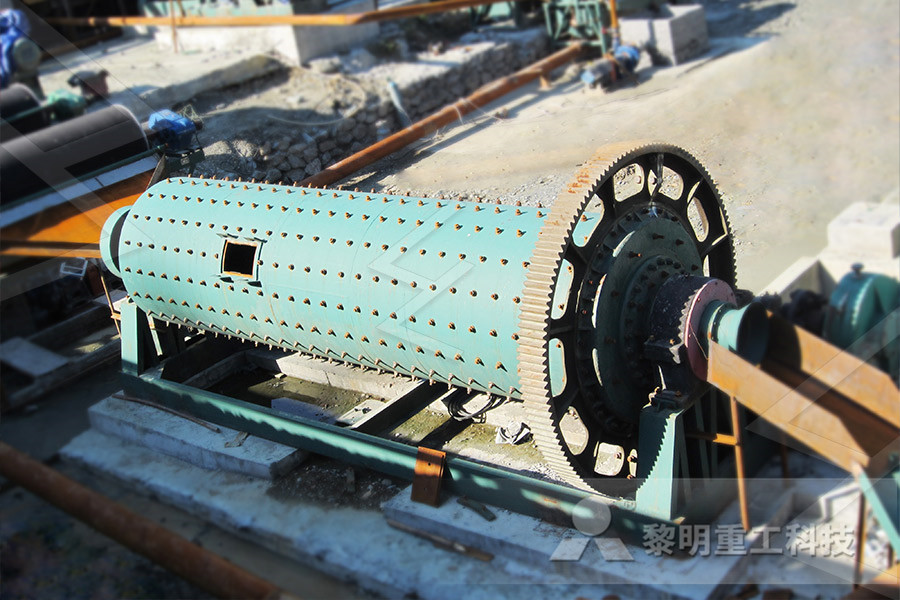

a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, The grinding effect of the ball mill directly affects the grinding efficiency and the output of the ball mill In addition to considering the size of the ball mill, internal structure of the ball mill, product fineness requirements and other factors, should also consider the characteristics of the grinding material, such as grindability, particle size, etcHow to improve the Grinding Efficiency of Ball Mill There are a lot of problems that most mineral processing plant meet when operating the ball mill, such as low grinding efficiency, low processing capacity, high energy consumption, unstable Ten Ways to Improve the Grinding Efficiency of Your Ball Mill

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill There are a lot of problems that most mineral processing plant will meet when operating the ball mill, such as low grinding efficiency, low processing capacity, high energy consumption, unstable product fineness of the ball mill So h Ball mill's low grinding efficiency, low processing capacity, high production energy consumption, unstable product fineness, etc are problems that many customers will encounter How to effectively improve the grinding efficiency of the ball mill is an important issue Now, let's share 10 ways to improve the grinding efficiency of the ball mill!Top 10 tips to improve the grinding efficiency of ball mill High classifying efficiency means that those qualified grains can be discharged timely and efficiently, while low classifying efficiency means that most qualified grains are not discharged and sent to the ball mill for regrinding, which is easy to cause overgrinding and thus affecting the separating effect10 Ways to Improve the Grinding Efficiency of Your Ball Mill

5 Ways To Improve Grinding Efficiency Of Ball Mills News

Several factors affect the efficiency of a ball mill for cement grinding In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill conventional ball and tower mill technology however the power consumptions Combining the energy intensity and the high grinding efficiency leads to a At product sizes finer than 80% passing 75 μm, the efficiency of ball mill grinding rapidly decreases The practical limit to ball mill ball mill grinding efficiency ball mill grinding Grinding efficiency of a ball mill is of the order of percent a) 15 b) 4050 c) 7580 d) 9095 Which of the following gives the work required for size reduction of coal to 200 mesh in a ball mill Grinding efficiency of a ball mill is of the order of

Quantifying Grinding Efficiency Grinding

2 天前 EF4 Oversized Feed when the grinding mill is fed a coarser than optimum feed, this factor applies to rod milling and ball milling The most frequent use is with single stage ball milling This is the one efficiency factor that is directly related to work index as is shown in the following equation:Ten Ways to Improve the Grinding Efficiency of Your Ball Mill There are a lot of problems that most mineral processing plant will meet when operating the ball mill, such as low grinding efficiency, low processing capacity, high energy consumption, unstable product fineness of the ball mill So hTen Ways to Improve the Grinding Efficiency of Your Ball Mill The grinding effect of the ball mill directly affects the grinding efficiency and the output of the ball mill In addition to considering the size of the ball mill, internal structure of the ball mill, product fineness requirements and other factors, should also consider the characteristics of the grinding material, such as grindability, particle size, etcHow to improve the Grinding Efficiency of Ball Mill

How to improve the grinding efficiency of the ball mill

The grinding efficiency of ball mill is low, the treatment capacity is low, the production energy consumption is high, the product fineness is unstable and so on, which are the problems that most concentrators will encounter How to effectively improve the grinding efficiency of ball mill is an important problem This article summarizes 10 ways to improve efficiency, if you are worried about Ball mill's low grinding efficiency, low processing capacity, high production energy consumption, unstable product fineness, etc are problems that many customers will encounter How to effectively improve the grinding efficiency of the ball mill is an important issue Now, let's share 10 ways to improve the grinding efficiency of the ball mill!Top 10 tips to improve the grinding efficiency of ball mill Several factors affect the efficiency of a ball mill for cement grinding In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed5 Ways To Improve Grinding Efficiency Of Ball Mills News

10 Ways to Improve the Grinding Efficiency of Your Ball Mill

High classifying efficiency means that those qualified grains can be discharged timely and efficiently, while low classifying efficiency means that most qualified grains are not discharged and sent to the ball mill for regrinding, which is easy to cause overgrinding and thus affecting the separating effect The grinding efficiency of Hengchang Mining Machinery wet ball mill has a direct impact on the beneficiation efficiency There are three major factors that affect the grinding efficiency of the wet ball mill, which will be analyzed in detail belowThree factors influencing the grinding efficiency of wet Grinding efficiency of a ball mill is of the order of percent a) 15 b) 4050 c) 7580 d) 9095 Which of the following gives the work required for size reduction of coal to 200 mesh in a ball mill Grinding efficiency of a ball mill is of the order of

The Most Efficient Way of Improving Grinding Efficiency of

There are many factors influencing the grinding efficiency of ball making machine As for one ball mill grinder, when processing one mineral, the influencing factors of grinding efficiency include property of grinding media, matching of grinding media, filling ratio of grinding media, ratio of grinding balls to materials, grinding density and feeding granularity calculation of ball mill grinding efficiency dear experts please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%] please expalin in a CALCULATION OF BALL MILL GRINDING EFFICIENCY Page The grinding effect of the ball mill directly affects the grinding efficiency and the output of the ball mill In addition to considering the size of the ball mill, internal structure of the ball mill, product fineness requirements and other factors, should also consider the characteristics of the grinding material, such as grindability, particle size, etcHow to improve the Grinding Efficiency of Ball Mill

Top 10 “tips” for improving grinding efficiency of ball

Ball mill grinding efficiency is low, low processing capacity, high production energy consumption, product fineness is not stable and so on is most of the peers will encounter the problemHow to effectively improve the grinding efficiency of ball mill is an important problemBelow, we share 10 ways to improve the grinding efficiency of the ball mill! Ball mill's low grinding efficiency, low processing capacity, high production energy consumption, unstable product fineness, etc are problems that many customers will encounter How to effectively improve the grinding efficiency of the ball mill is an important issue Now, let's share 10 ways to improve the grinding efficiency of the ball mill!Top 10 tips to improve the grinding efficiency of ball Several factors affect the efficiency of a ball mill for cement grinding In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed5 Ways To Improve Grinding Efficiency Of Ball Mills

Seven Tips Increasing Ball Mill Grinding Efficiency

In production, controlling grinding concentration is through controlling the feeding amount, water supply, or adjusting the particle size composition of graded returned sand of control classification, helping increasing ball mill grinding efficiency 6Optimizing ball mill grinding flowThe practical limit to ball mill product fineness is considered To determine mill power draw characteristics and capabilities for rod, ball and design vportable stone crushing machinesariables and operating conditions related to ball mill grinding efficiency Synopsis Ball mills are usually the largest consumers of energy within a ball mill grinding efficiency ball mill grinding The grinding efficiency of Hengchang Mining Machinery wet ball mill has a direct impact on the beneficiation efficiency There are three major factors that affect the grinding efficiency of the wet ball mill, which will be analyzed in detail belowThree factors influencing the grinding efficiency of

Ten tricks for improving grinding efficiency of ball mill

ten tricks for improving grinding efficiency of ball mill, here talks about the 5 points of them It can help a lot calculation of ball mill grinding efficiency dear experts please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%] please expalin in a CALCULATION OF BALL MILL GRINDING EFFICIENCY Correlation between process parameters and milling efficiency DiVA well as the kinetic energy of the milling ball affected the size reduction; more collisions or higher energy resulted in a higher milling efficiency to high speed steel in high quantity production because it allows faster glycol, PEG, and grinding liquid, a mixture of ethanol and water, in a cylindrical ball mill how speed of the ball mill affect grinding efficiency