Wagon Tippler Design Cable Train Scribd

Wagon tippler is a facility where the coal is unloaded from railway wagons one by one by holding and tippling the wagon upside down into hopper below The coal discharge from the wagon is collected in hoppers and then evacuated by APPRON feeder on to conveyors Wagon tippler The design life of the equipment, particularly the fatigue life of Wagon Tipplers which are subject to arduous stress reversals during unloading, is also vital because the replacement of these machines is costly and can interrupt production for several weeks in cases where operators do not have adequate redundancy orWAGON TIPPLER docswixstaticTippler retains wagon from top as well as from side by using clamping devices provided on it Apart from that track stops, wheel grippers and different type of limit switches are provided as features of wagon tippler Tippler is driven by either Hydraulic drive or by electromechanical drive Wagon Tipplers Elecon

Wagon Tippler ISKAR Muhendislik Ltd

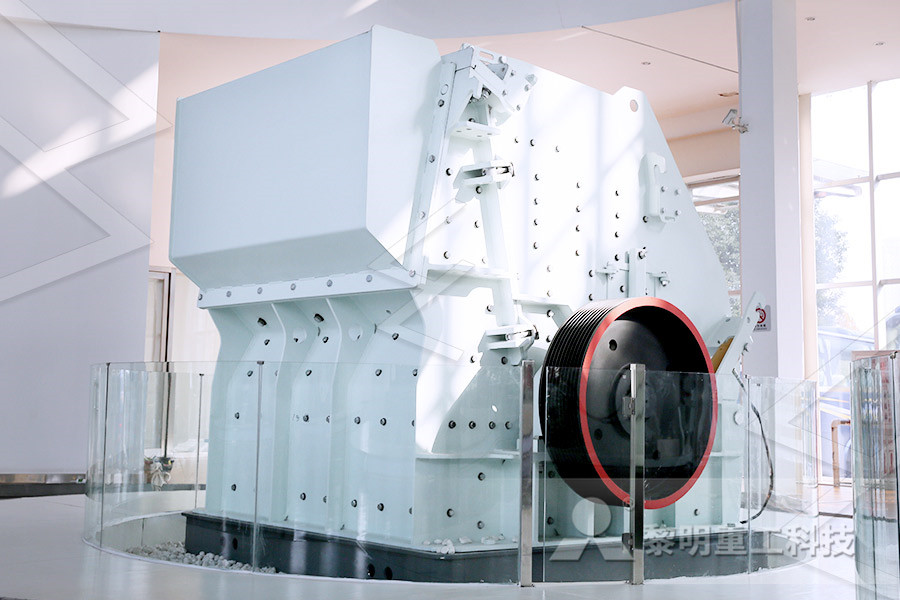

ISKAR wagon tipplers secure the wagon to be tipped from top by three or four hydraulic clamping arms depending on the wagon length The tippler drive and clamping arms are powered by a single, open loop circuit type, electric motor driven, hydraulic powerpacks unit (HPU) The Wagon Tippler is of robust construction and designed for continuous duty wagon tipplers WAGON TIPPLER Q=130 t LOAD CAPACITY 130 tWAGON TIPPLERS FMK These wagons are unloaded in a wagon tippler by tipping the wagon over the appropriate storage hoppers A schematic diagram of the process flow is shown in Fig 1 (a) Side arm chargers of the wagon tippler are used for positioning single/double wagons on the tippler platform for unloading also for pushing the empty wagons out of the platformImprovement of wagon tippler disc spring life by

Railcar Dumpers (Wagon Tipplers)

Rolled “T” end rings Reduces structural stress and extends service life by utilizing a standard “T” shape to construct the flange and portion of the web Promotes extended barrel life A special fiveyear warranty is offered by on rolled “T” end rings Wheel clamps Secures railcar in place during dumper rotationThe wagon tippler is designed to unload materials like Coal, Coke, Lignite, Iron Ore, Limestone, dolomite etc from the open type railway wagons viz; BOY,BOX,BOXN ,BOXNHA, BOXNHL, BOXN25, DFC25, DFC325 MKD11 I OZ/0 etcWagon Tippler, वैगन टिपलर in Burma Mines, developed an optimum design system which included a hood, duct, fan and a cyclone separator to separate solid dust particles from the air stream Key words Coal handling, dust minimization, cyclone separator, coal dust 1 Introduction Approximately 60% of total electrical power production in Zimbabwe is generated by coal fired thermal power plantsDevelopment of a dust minimization system for the coal

Luvkush Kumar System Design Engineer ( Electrical

Worked as Electrical Design Engineer (Heavy Machinery Dragline Shovels) o Prepared Electrical Schematics In AutoCad o Solved Electrical Design / Field defects Issues on Electrical Mining machines 8200AC W2000DC Draglines o Worked on after market projects o Motors,Drive, Accelerometers, strain gauges IBA data analysis, DATKRotaside dumpers for random cars lift the car during dumping, therefore reducing the depth of the receiving hopper and foundation This Cframe (crescent) design allows the positioner to move through the barrel, promoting efficient handling of random cars Train simulation program ’s train simulation program evaluates the dynamics of the train configurations for the facilityRailcar Dumpers (Wagon Tipplers) We have wagon tippler for empting out the railway wagons, which bring coal for our power plants The machine was installed in 1984 and was running almost trouble free But recently, machine started drawing higher ampers and gearbox temperature was increasing beyond acceptable limit The gearbox is worm wormwheel typeWagon Tipplers CR4 Discussion Thread

wagon tippler and side arm charger calculation

Standard Design Criteria – Central Electrical Authority wagon tippler, trash hopper unloading and reversible yard conveyer) Therefore, for calculation of belt conveyor capacity, their drives and drive motors The side arm charger shall be suitable to handle 59 nos of Hmc Equipments Pvt Ltd Offering Wagon Tippler DS System, वैगन टिपलर, DS System in Industrial Area, Bilaspur, Chhattisgarh Read about company Get contact details and address ID: Wagon Tippler DS System, वैगन टिपलर in Industrial Wagon Tippler EPC EPC Profile EPC Cases Bulk Material Handling System Services Supply of Spare Parts Operation Support Services Technical modification Site Installation and AfterSale Services Global Domestic Market Foreign market Contact大连世达重工有限公司

Wagon Design WELCOME TO RDSO

Welcome to Wagon Directorate The objective of this directorate is to design freight wagons and their related components and ancillary equipments New designs of wagons have been developed by Wagon Directorate for a wide range of commodities and consignments, the largest being a 28axle wagon of 296 tonnes carrying capacityThis design basis report (DBR) forms the basis for detailed engineering112 The scope of this document includes design of the electrical distribution system for the terminal ie downstream of 33 kV switchgear up to the respective load centers through power control centers (PCCs) / distribution boards(PDF) Electrical DBRpdf Prabir Datta Academiaedu plant (excluding the Interconnection path, wagon tippler and part of Electrical and CI) job covers the part Coal handling system of 1X500 MW FGUTPP Stage – IV, to be done as turnkey including design, engineering, manufacture, supply, assembly, inspection and testing atVOLUMEIIIE ANNEXURES, FORMATS ETC VOLUME IIIE

Shambhu Ambasta Principal Electrical Engineer

My responsibilities were design, engineering, procurement, installation, testing and commissioning of electrical equipment for Bulk Material Handling systems consisting of belt conveyor, Crusher, Vibrating screen, Wagon tippler and Stacker cum Reclaimer mobile machinesEngineering/ Design support for Electrical control upgrades of MD6640 Electrical Drill Machine Mathwork Simulation support power system analysis (DC to AC conversion of DC drives and motors Engineering/Design support for Electrical Rope shovels 7495 New Product Improvement programs aftermarket projectsLuvkush Kumar System Design Engineer ( Electrical Wagon Tippler Design Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This presentation gives an idea of wagon tippler design used for coal unloadingWagon Tippler Design Cable Train

wagon tippler and side arm charger calculation

Standard Design Criteria – Central Electrical Authority wagon tippler, trash hopper unloading and reversible yard conveyer) Therefore, for calculation of belt conveyor capacity, their drives and drive motors The side arm charger shall be suitable to handle 59 nos of Hmc Equipments Pvt Ltd Offering Wagon Tippler DS System, वैगन टिपलर, DS System in Industrial Area, Bilaspur, Chhattisgarh Read about company Get contact details and address ID: Wagon Tippler DS System, वैगन टिपलर in Industrial We have wagon tippler for empting out the railway wagons, which bring coal for our power plants The machine was installed in 1984 and was running almost trouble free But recently, machine started drawing higher ampers and gearbox temperature was increasing beyond acceptable limit The gearbox is worm wormwheel typeWagon Tipplers CR4 Discussion Thread

Powerpack For Wagon Tippler

Wagon tippler design calculation wagon tippler design calculation stone crusher machine and high reduction ratio from large primary jaw crusher and impact crusher get quote issn 23951621 design analysis of puller cum pusher with powerpack forWagon Tippler EPC EPC Profile EPC Cases Bulk Material Handling System Services Supply of Spare Parts Operation Support Services Technical modification Site Installation and AfterSale Services Global Domestic Market Foreign market Contact大连世达重工有限公司 Calling Expression of Interest (EOI) for dismantling shifting of existing close wagon tippler of stage – I to 660 MW along with design, engineering, supply, installation, commissioning, operation maintenance of wagon tippler on BOT ( Build,Operate Transfer) basis for CLOSE WAGON TIPPLER OF STAGE I TO 660 MW AT

VOLUMEIIIE ANNEXURES, FORMATS ETC VOLUME IIIE

plant (excluding the Interconnection path, wagon tippler and part of Electrical and CI) job covers the part Coal handling system of 1X500 MW FGUTPP Stage – IV, to be done as turnkey including design, engineering, manufacture, supply, assembly, inspection and testing atMy responsibilities were design, engineering, procurement, installation, testing and commissioning of electrical equipment for Bulk Material Handling systems consisting of belt conveyor, Crusher, Vibrating screen, Wagon tippler and Stacker cum Reclaimer mobile machinesShambhu Ambasta Principal Electrical Engineer Engineering/ Design support for Electrical control upgrades of MD6640 Electrical Drill Machine Mathwork Simulation support power system analysis (DC to AC conversion of DC drives and motors Engineering/Design support for Electrical Rope shovels 7495 New Product Improvement programs aftermarket projectsLuvkush Kumar System Design Engineer ( Electrical