crusher for cubical shaped aggregates hpkneisde

crusher for cubical shape aggregate Mine Equipments Aggregate Production For Superpave HMA The University of Texas A uniform rock feed will produced more consistent aggregate shapes and gradation handles all types of material and usually provides the most cubical aggregates How the crusher crushes the material will determine particle shapeCrusher stage: aggregate shape is improved while progressing through the stages 10 will be needed after the cone crusher for shaping the outputs into cubic shape Crush for Cubical Aggregate Asphalt Pro Quite simply the cubical shape is strong; cubical aggregates lock together creating a strong pavement which is why a very high cubical crusher for cubical shaped aggregates lafossaesThe type of material plays a big part in how you’re going to process the material Different rock types favor cubical aggregate production Chert or flint from a sand and gravel pit will fracture into sharp slivers On the other hand, cubical shape can be created from granite or limestone or natural gravel or dolomiteThe Benefits of Cubical Aggregate AsphaltPro

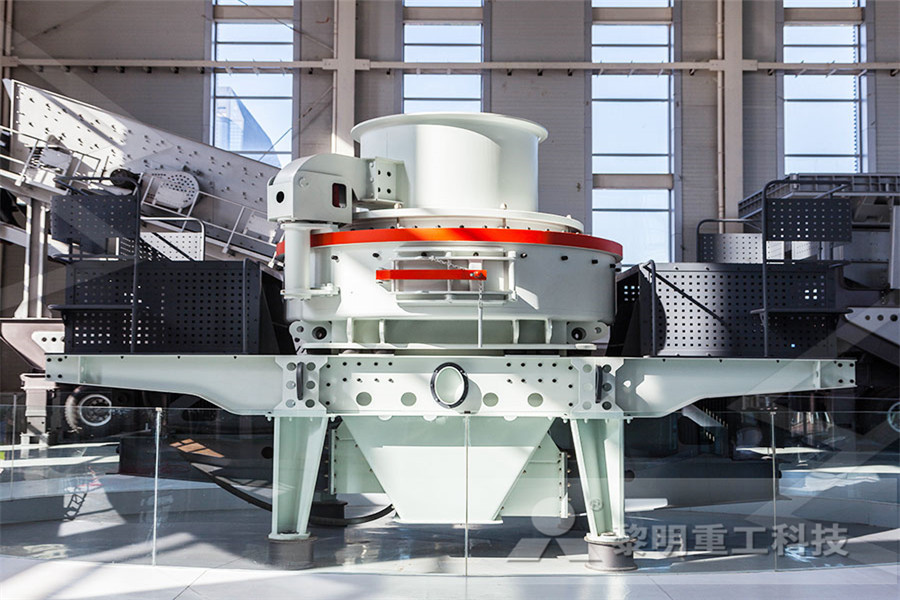

Producing Cubical Shape Aggregate

If the secondary crusher hopper isn't kept full (choke fed) during operation, problems with flat and elongated particles will be magnified Adjustments in the reduction ratio also help to control particle shape As noted in the article, decreasing the reduction ratio generally produces a more nearly cubical aggregate shapecrusher for cubical shape aggregate This page is provide professional crusher for cubical shape aggregate information for you, we have livechat to answer you crusher for cubical shape aggregate Cubical Shape Crusher Mills, Cone Crusher, Jaw If the secondary crusher hopper isn't kept full (choke fed) during operation, problems with flat and elongated particles will be magnified Adjustments in the reduction ratio also help to control particle shape As noted in the article, decreasing the reduction ratio generally produces a more nearly cubical aggregate shapeProducing Cubical Shape Aggregate

SALIENT FEATURES : METAL TO ROCK CRUSHING

The MARSMAN HSI (Horizontal Shaft Impact Crusher) is used to produce high quality cubical shape stone aggregate material They fetch a high ratio of reduction, direct control of product gradation and excellent cubical product shape Available in the best type of stone crusher to get cubicle shape aggregates cone crusher or jaw crusher Choose suitable crusher plant for work according to clients requirements, stone crushing production line combination and classification of finished particles can be conducted vibrating feeder jaw crusher muticylinder hydraulic cone crusher reshaping machine sand making machine vibrating screenthe best type of stone crusher to get cubicle shape A cubical aggregate allows to reduce the amount of cement and water, while still producing a strong concrete product, so it is better and the benefit is similar for asphalt The shape factor of aggregate plays a vital role in the design and performance of mix and it is mainly influenced by feed rock properties, the type of crusher, and the way oducing cubical shaped aggregates

Effect of crusher operation on coarse aggregate shape A

For crushed aggregate, cubical or nearly cubical particles are preferred As the number of flat and elongated particles increases, concrete workability decreases Effect of crusher operation on coarse aggregate shape Particle shape is influenced by feed rock properties, the type of crusher, and the way in which the crusher is operatedThe cone crusher's optimised speed and improved crushing chamber design provides high productivity with less wear on parts, meaning a great savings in labour Designed for crushing soft and mediumhard materials with close grain distribution and good cubical shape ratios, tertiary impact crushers are an excellent solution in the production Crushers The cubicity of the cone crusher product can be improved with the proper circuit design, screen selection and crusher operating parameters The particle shape in relation to the CSS This relates to two of the 10 points listed for cubical product shape, eg setting close to the desired product size and using the correct flow sheetThe pros and cons of cone crusher applications – Quarry

The effect of rock crusher and rock type on the

The effect of the crusher type on the characteristics of shape is more in the marble and less in the tuff aggregates • Aggregate produced from HSI showed a higher cubical form, angularity, and roughness rather than JC • The problems due to undesirable aggregate form can be solved by selecting a suitable crusher based on rock type The two most important factors when producing sand and aggregate is shape (referred to as cubical crushed particles) and maximum yield of highest value product Every successful aggregate producer can achieve both with the right raw materials, the right equipment, the right flow sheet and the right operation of equipmentsand and aggregates, crushing, maximum yieldCrusher stage: aggregate shape is improved while progressing through the stages 10 will be needed after the cone crusher for shaping the outputs into cubic shape Crush for Cubical Aggregate Asphalt Pro Quite simply the cubical shape is strong; cubical aggregates lock together creating a strong pavement which is why a very high cubical crusher for cubical shaped aggregates

SALIENT FEATURES : METAL TO ROCK CRUSHING

The MARSMAN HSI (Horizontal Shaft Impact Crusher) is used to produce high quality cubical shape stone aggregate material They fetch a high ratio of reduction, direct control of product gradation and excellent cubical product shape Available in the best type of stone crusher to get cubicle shape aggregates cone crusher or jaw crusher Choose suitable crusher plant for work according to clients requirements, stone crushing production line combination and classification of finished particles can be conducted vibrating feeder jaw crusher muticylinder hydraulic cone crusher reshaping machine sand making machine vibrating screenthe best type of stone crusher to get cubicle shape The cone crusher's optimised speed and improved crushing chamber design provides high productivity with less wear on parts, meaning a great savings in labour Designed for crushing soft and mediumhard materials with close grain distribution and good cubical shape ratios, tertiary impact crushers are an excellent solution in the production Crushers

oducing cubical shaped aggregates

A cubical aggregate allows to reduce the amount of cement and water, while still producing a strong concrete product, so it is better and the benefit is similar for asphalt The shape factor of aggregate plays a vital role in the design and performance of mix and it is mainly influenced by feed rock properties, the type of crusher, and the way For crushed aggregate, cubical or nearly cubical particles are preferred As the number of flat and elongated particles increases, concrete workability decreases Effect of crusher operation on coarse aggregate shape Particle shape is influenced by feed rock properties, the type of crusher, and the way in which the crusher is operatedEffect of crusher operation on coarse aggregate shape A The cubicity of the cone crusher product can be improved with the proper circuit design, screen selection and crusher operating parameters The particle shape in relation to the CSS This relates to two of the 10 points listed for cubical product shape, eg setting close to the desired product size and using the correct flow sheetThe pros and cons of cone crusher applications – Quarry

CRUSHING SCREENING

TERTIARY IMPACT CRUSHER EXCELLENCE IN PRODUCTION OF FINE AGGREGATES FOR CONCRETE AND ASPHALT Designed for crushing soft and mediumhard materials with close grain distribution and good cubical shape ratios, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applicationsMOBILE PROCESSING Wirtgen Group Worldwide, including in India and Turkey Besides Germany, also found in south England shape is challenging during the production of asphalt aggregate grain sizes produced by the jaw crusher are tolerated by the cone crusher eg with a scalper upstream from the crushing plant, can be applied where necessarycan cone crushers produce aggregates of round Shape of aggregates can get influenced by not only the characteristics of parent rocks but also by the type of crusher used to crush the rocks Most of the jaw crushers with plain jaws will give flaky aggregate, while with footed jaws will give cubical ore But it is the cone crusher which will give perfectly cubical aggregates Also Read:Shape Wise Classification of Aggregates