Vibrating Grizzly Feeder Advantage Series

Vibrating Grizzly Feeder Advantage Series Refer to the appropriate Operator’s Manual for instructions on the proper use of this equipment Failure to follow the appropriate Operator’s Manual when using our equipment or failure to act responsibly may result in serious injury or death • Standard feeder sizes range from 33" x 12' to 86" x 30' • Grizzly feeder components include: – Deepsided feeder trough made up of a partial pan and one or more grizzly sections – A vibrating drive assembly – A spring support system • Fixed or adjustable grizzly openings to maximize flexibility and productivityGrizzly Feeders HeavyDuty Pan Feeders Static Feeder Vibrating Grizzly Feeder Get the most out of your primary crusher by feeding only what needs to be crushed with a Cedarapids® vibrating grizzly feeder (VGF)Cedarapids Vibrating Grizzly Feeders MPS

Grizzly Feeders, Vibrating Grizzly Feeder, Industrial

The vibrating grizzly feeder is used to separate ROM feed material into fractions prior to the primary crushing stage of the process Login/Register +27 11 820 520 Intrepid Vibrating Grizzly Feeders are made up of a pan section on one end followed by a series of evenly spaced steel bars at the other Material is fed to the pan — usually by a loader — and carried across by a vibrating force The vibration also helps move finer particles to the bottom of the loadIntrepid® Vibrating Grizzly Feeder VGF Superior The grizzly feeder reduces maintenance and capital costs by scalping only large material to your crusher or rip rap pile, while fines pass through the grizzlies to be screened or discarded Simplicity® Vibrating Grizzly Feeder units can be customized Simplicity GF Series Vibrating Grizzly Feeders

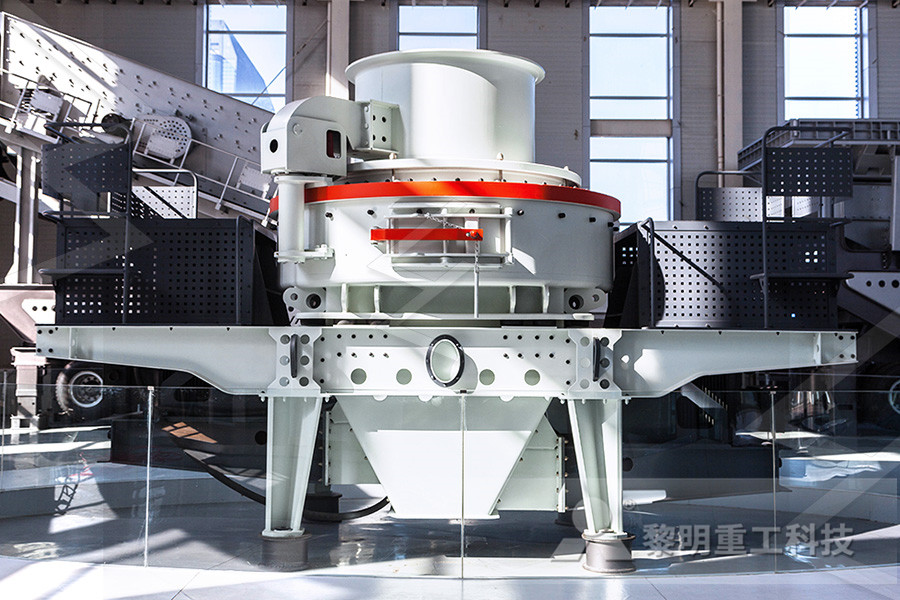

Vibrating Grizzly Feeder China Henan Zhengzhou

Vibrating grizzly feeder adopts imported manufacturing technology in Finland, Sweden, frame type ring vibrator Kai rivet connection structure, firm structure, high strength, wear resistance 2 Vibrating grizzly feeder using manganese steel plate and bar with enough rigidity, can withstand the impact of large stone Vibrating grizzly feeders combine a pan section followed by at least one section of grizzly bars Grizzly feeders are typically positioned under a dump hopper that is fed by haul trucks or loaders The grizzly sections act to remove excess fines prior Vibrating Grizzly Feeders Deister Machine Company, These feeders incorporate grizzly sections at the discharge end to remove undersize rock and ore before the primary crushing station Key features/benefits The material load on the feeder is moved along by two parallel contrarotating shafts geared together The linear motion of the vibrating assembly is easily adjustable between 30 and 55 Trio® TF Series Grizzly Feeders Weir Group

TROUBLESHOOTING VIBRATORY FEEDER SYSTEMS

The feeder bowl unit properly sorts and orientates the parts in preparation to be transferred by the inline drive component The feeder bowl relies on a vibratory drive unit to propel parts clockwise or counter clockwise dependent on the application With the use of custom bowl tooling, a part can be expelled in any orientation desired Approximate grizzly throughput is 5 stph x square foot of grizzly area x nominal opening Calculations based on 100 lb/ft3 material weight Example: 45" feeder, 5' grizzly, 4" nominal opening: 5 stph x 1875 square feet grizzly area x 4" nominal opening = 375 stphSiMpliCitY VGF ViBRatinG GRiZZlY FEEDERS High Capacity Vibrating Grizzly Feeder Effective Date: March 2012 Product specifications and prices are subject to change without notice or obligation The photographs and/or drawings in this document are for illustrative purposes only Refer to the appropriate Operator’s Manual for instructions on the proper use of this equipmentADVANTAGE SERIES VIBRATING GRIZZLY FEEDERS

Vibrating Grizzly Feeders McLanahan

The McLanahan Vibrating Grizzly Feeder has a history of reliability and durability McLanahan offers feeders in five different widths to match up to the crusher opening width For example, McLanahan designs feeders with shallower sides for use in portable plants where over plant height is limited Vibrating grizzly feeder using manganese steel plate and bar with enough rigidity, can withstand the impact of large stone 3 Vibrating grizzly feeder discharge side has special bar structure, the gap can be adjusted at the same time, give full play to the effect of back breaking machineVibrating Grizzly Feeder China Henan Zhengzhou Intrepid Vibrating Grizzly Feeders are made up of a pan section on one end followed by a series of evenly spaced steel bars at the other Material is fed to the pan — usually by a loader — and carried across by a vibrating force The vibration also helps move finer particles to the bottom of the loadIntrepid® Vibrating Grizzly Feeder VGF Superior

Vibrating Grizzly Feeders Telsmith

Vibrating Grizzly Feeders Telsmith vibrating grizzly feeders are available in sizes ranging from 36″ x 12′ up to 72″ x 34′ and in a variety of models and configurations such as Outotec offers an extensive range of grizzly designs with customizable configurations to fit your needs VF Series™ grizzly feeders can be optimized through a wide range of options You can choose an electrical or hydraulic drive, a steel or rubber lining, a vibrating chute underneath the grizzly section, and an automatic greasing unitVF Series grizzly feeders OutotecVibrating feeder is a kind of common feeding equipment In production, it can send blocky or granular materials to the followup equipment evenly and continuously This is the first working procedure of the whole production line The installation and operation of the vibrating feeder Vibrating Feeders Operation And Maintenance

Home Page Goodwin Barsby

Range of Vibrating Grizzly Feeders upto 500 tonnes per hour Read More Genuine Spare Parts Large stock inventory of current build and 'classic' crusher, screen and feeder component parts Read MoreUNITED STATES HEAD OFFICE Groundwork Group LLC 3422 Old Capitol Trail, Suite 700 PMB 41 Wilmington, DE 19808 – 6124 International Sales +1 844 295 8047PARTS ORDER GroundworkThe McLanahan Vibrating Grizzly Feeder has a history of reliability and durability McLanahan offers feeders in five different widths to match up to the crusher opening width For example, McLanahan designs feeders with shallower sides for use in portable plants where over plant height is limitedVibrating Grizzly Feeders McLanahan

Crushing Model 504432T Screening Sand Prep

Introduction to the Vibrating Feeder Vibrating Feeder 15 The following is a brief description of the vibrating feeder’s basic parts and their function Pan Assembly The pan assembly is the framework of the feeder The wear plates, grizzly bars, support springs, and vibrating mechanism bolt to the pan assembly The pan assemblyVibrating Grizzly Feeders Telsmith vibrating grizzly feeders are available in sizes ranging from 36″ x 12′ up to 72″ x 34′ and in a variety of models and configurations such as Vibrating Grizzly Feeders Telsmith Vibrating grizzly feeders combine a pan section followed by at least one section of grizzly bars Grizzly feeders are typically positioned under a dump hopper that is fed by haul trucks or loaders The grizzly sections act to remove excess fines prior to the primary crusherVibrating Grizzly Feeders Deister Machine Company, Inc

MODEL G4179 1 HP Grizzly

Power Feeder This machine is part of a growing Grizzly family of fine woodworking machinery When used according to the guidelines set forth in this manual, you can expect years of troublefree, enjoyable operation and proof of Grizzly’s commitment to customer satisfaction The specifications, drawings, and photographssvedala mn vibrating grizzly feeder Flow Control has become a separately listed independent company called Neles Neles is a flow control solutions and services provider for oil and gas refining, pulp, paper and the bioproducts industry, chemicals, and other process industriessvedala mn vibrating grizzly feeder Bussa Machineryvibrating grizzly feeder design calculations Australia vibrating grizzly feeder design calculations Australia How to Design Efficient and Reliable Feeders for Bulk Solids by John W Carson PhD and Greg Petro PE A feeder is an extremely important element in a bulk material handling system since it is the means by which the rate of solids flow design calculation of vibrating feeder

VF Series grizzly feeders Outotec

Outotec offers an extensive range of grizzly designs with customizable configurations to fit your needs VF Series™ grizzly feeders can be optimized through a wide range of options You can choose an electrical or hydraulic drive, a steel or rubber lining, a vibrating chute underneath the grizzly section, and an automatic greasing unitGrizzly Vibrating Feeder GVFH Even a frame side plate is possible to change as parts Features Knockdown type screen that consists of every single part Everybody can easily build up this machine with building up manual Easy transfer with its light weightSCREEN / FEEDER Nakayama Iron WorksVibrating feeder is a kind of common feeding equipment In production, it can send blocky or granular materials to the followup equipment evenly and continuously This is the first working procedure of the whole production line The installation and operation of the vibrating feeder Vibrating Feeders Operation And Maintenance