Fly Ash Bricks, Fly Ash Brick Manufacturers, Suppliers

Fly Ash Bricks or FAB refer to those bricks that are lighter in weight and stronger than other bricks They are manufactured by using industrial waste They not only create ample opportunities for proper and useful disposal of waste without emitting harmful gases but also control environmental pollution to Fly ashbased geopolymer specimens have been prepared as follows: powdered materials were previously dry mixed and homogenized, and then the activator solution was added to the dry mixture The alkaline activator solution has been prepared mixing sodium silicate solution (SS) with 10 M sodium hydroxide solution (N)Reuse of mining waste as aggregates in fly ashbased possibility of geopolymer manufacturing from fine fly ash (Class F) and Alkaline solution, then studied the hardened properties of fly ash bricks with addition of lime and gypsum In this paper, we have studied the composition of highstrength fly ashlime bricks using a fine pulverized fuel ash classFEvaluate properties of fly ash based Geopolymer Bricks

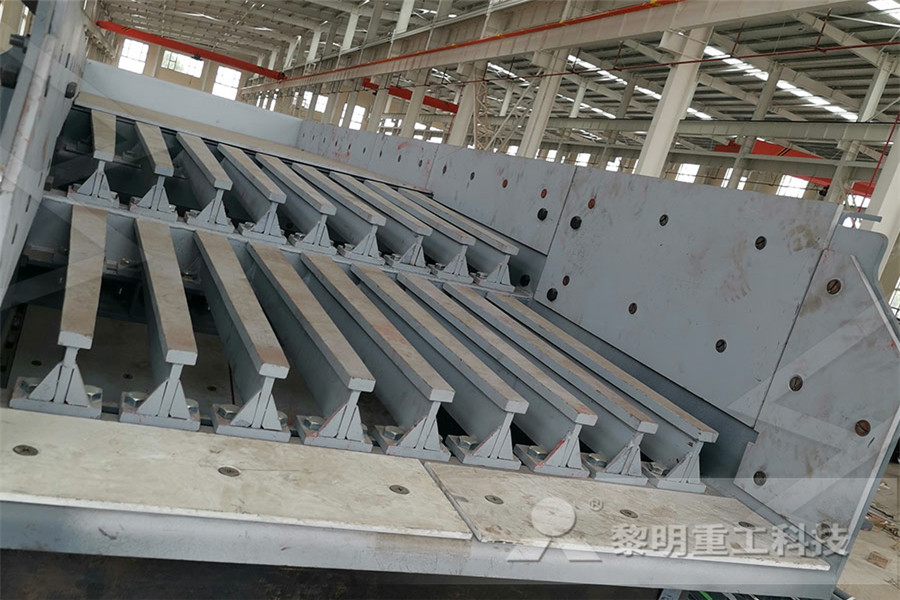

Conveyor Belt Solutions for every mining task

Flowchart of mining and manufacturing 4 of iron concentrate Flowchart of mining, processing, combustion 6 of coal and further utilisation or disposal of fly ash at a mining and power plant company Conveyor belts for every mining application 8 Challenges solutions Extreme temperatures / Superior 10 heat and coldresistant conveyor beltsManufacturer of Natural Minerals, Stone Chips Fly Ash Bricks And Fully Automatic Block Making Plant offered by Utkal Minerals Private Limited from Keonjhar, Odisha, IndiaUtkal Minerals Private Limited, Keonjhar Iron Ore Mining and Processing Clay and Sand Bricks Plant Fuel Bricks From Groundnut, Soyabean Hull Jute Megnesium Metal INTERGRINDING OF FLY ASH WITH PORTLAND CEMENT CLINKER NON COKING COAL TO COKING COAL (CONVERSION BY BURNING) WET GROUND MICA GLASS BOTTLE FROM SCRAP RCC BRICKS (USED IN PETROL PUMP FLOORING) BRICKS GLAZINGDetailed Project Reports NIIR

Physicalmechanical properties of soilcement bricks

Cicek T, Tanrıverdi M (2006) Lime based steam autoclaved fly ash bricks Contruction and Building Materials 21:1295–1300 Google Scholar Collares EG, Francklin I Jr, Motta LAC (2012) Evaluation of the aggregate produced from wastes of quartzite mining sites to use in concrete Int J Geotech Geoenv Eng 35(3):251–215 Among other applications, fly ash is used as material to make bricks, ceramic tiles, and plaster; as filler in metal and plastic composites and in paints and adhesives; and as structural fill for A New Life For Coal Ash CEN Energo offers end to end solution for material handling systems for mining, coal handling, bulk conveying, port handling and ash handling Energo is an advanced material handling system integrator committed to help the customers enhance their capabilitiesMining, Coal, Port Ash Material Handling Systems

Studies On Flyash As An Adsorbent For Removal Of

ore mining can also produce acetic acid 15 Literature Review Studies carried out by Wang and Wu revealed that unburned carbon component in fly ash plays an important role in adsorption capacity[1] There are many research reports on work that have been carried out in the field of adsorption techniques for the removalIron Ore Mining and Processing Clay and Sand Bricks Plant Fuel Bricks From Groundnut, Soyabean Hull Jute Megnesium Metal INTERGRINDING OF FLY ASH WITH PORTLAND CEMENT CLINKER NON COKING COAL TO COKING COAL (CONVERSION BY BURNING) WET GROUND MICA GLASS BOTTLE FROM SCRAP RCC BRICKS (USED IN PETROL PUMP FLOORING) BRICKS GLAZINGDetailed Project Reports NIIR2002 Implemented an integrated Oraclebased ERP solution 2003 Commenced a fly ash brick plant of 6000 units per day to utilize hazardous fly ash from captive power plant CECL installed third 9 MVA ferro alloys furnace 2004 Commenced extraction from RASL iron ore Sarda Energy Minerals Ltd

news machines for bricks in punjab Mining

Fly ash bricks set to take Punjab company places Fly ash bricks set to take Punjab company places: The company has plans to invest Rs 60 lakh in four more machines, Australia New Zealand »More detailed A PRISM solution () 06 View From The Top 08 The Sarda Seven A law and order problem led to the suspension of our iron ore mining operations There was a decline in the selling prices of Apart from setting up a stateoftheart fly ash bricks plant and the pellet plantSARDA’S STRATEGY FOR SUSTAINABLE GROWTHFly ash is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue gases The fly ash produced from the burning of younger lignite or subbituminous coal, in addition to having pozzolanic properties, also has selfcementing propertiesCopper Tailing an overview ScienceDirect Topics

Low Cost Building Material

mining, domestic and source of solid waste are Fly ash and bottom ash: Generally the ash is generated from the thermal power plant for generate the electricity as well as it is a byproduct from municipal solid waste It is also obtained from coal combustion is frequently used inHollow Bricks – Hotfrog INDIA – free local business directory We are one of the main manufacturers of the Fly Ash Bricks in Tamil Nadu Starwin Hollow Bricks pav THRISSUR, KERALA C K Hollow Bricks Pudur K PALAKKAD, KERALA »More detailedhollow bricks manufacturers kerala thrissur Setting Up Plant For Manufacture Of Fly Ash Bricks Of fly ash bricks manufacturing plantProject report on flyash bricksDetailed process ofSetting up of aac plant for manufacture of aac blocks ; Live Chat; High Performance Bricks From Fly Ash Table 1 summarises the differences in the manufacturing process between the clay bricks and the Mini Aac Blocks Manufacturing Process Project Report

Physicalmechanical properties of soilcement bricks

Several geotechnical studies have been carried out with the purpose of making tailings from quartzite mining an alternative source of raw material for different purposes in engineering works or civil construction This study analyzed the physicalmechanical behavior of soilcement bricks made with the addition of quartzite mining tailings from the southwest region of the State of Minas Gerais2002 Implemented an integrated Oraclebased ERP solution 2003 Commenced a fly ash brick plant of 6000 units per day to utilize hazardous fly ash from captive power plant CECL installed third 9 MVA ferro alloys furnace 2004 Commenced extraction from RASL iron ore Sarda Energy Minerals LtdIron Ore Mining and Processing Clay and Sand Bricks Plant Fuel Bricks From Groundnut, Soyabean Hull Jute Megnesium Metal INTERGRINDING OF FLY ASH WITH PORTLAND CEMENT CLINKER NON COKING COAL TO COKING COAL (CONVERSION BY BURNING) WET GROUND MICA GLASS BOTTLE FROM SCRAP RCC BRICKS (USED IN PETROL PUMP FLOORING) BRICKS GLAZINGDetailed Project Reports NIIR

Conveyor Belt Solutions for every mining task

Flowchart of mining and manufacturing 4 of iron concentrate Flowchart of mining, processing, combustion 6 of coal and further utilisation or disposal of fly ash at a mining and power plant company Conveyor belts for every mining application 8 Challenges solutions Extreme temperatures / Superior 10 heat and coldresistant conveyor beltsFly ash from Pulp and Paper Mills: A Potential Soil Amendment The mills produce about 11 300 tonnes of fly ash per year The fly ash was carried out during the period when the proportion of bark and wood residues (55 %) and peat (45 %) was a typical for the Get Pricefly ash mill developments Prominer (Shanghai) Fly ash is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue gases The fly ash produced from the burning of younger lignite or subbituminous coal, in addition to having pozzolanic properties, also has selfcementing propertiesCopper Tailing an overview ScienceDirect Topics

Low Cost Building Material

mining, domestic and source of solid waste are Fly ash and bottom ash: Generally the ash is generated from the thermal power plant for generate the electricity as well as it is a byproduct from municipal solid waste It is also obtained from coal combustion is frequently used inSolutions for every mining task Content Flowchart of mining and manufacturing 4 of iron concentrate Flowchart of mining, processing, combustion 6 of coal and further utilisation or disposal of fly ash at a mining and power plant company Conveyor belts for every mining application 8 Challenges solutions Extreme temperatures / Superior 10 heat and coldresistant conveyor belts Fire / Flame Conveyor Belt Solutions Continental Industry Vecor has developed a process that sinters the fly ash, adding a patented compound that turns fly ash into a rocklike substance that is suitable for making tiles, bricks and pavers Compared to clay tiles, the Vecor tiles offer a 30 percent saving in energy and emissions, while the bricks have 10 times better thermal insulation properties, are Vecor VentureRadar

Physicalmechanical properties of soilcement bricks

Several geotechnical studies have been carried out with the purpose of making tailings from quartzite mining an alternative source of raw material for different purposes in engineering works or civil construction This study analyzed the physicalmechanical behavior of soilcement bricks made with the addition of quartzite mining tailings from the southwest region of the State of Minas Gerais Approximately 18,000 ha of land is currently under mining operations in Goa (Kumar, 2000)The present mining rate of 16–21 million ton of ore, with high oreover burden ratio of around 1:3, means that there is a need of removal and disposal of 40–50 million m 3 of waste per year Having exhausted the available area for waste dumps within leasehold area, the mining companies had to Reuse of iron ore mineral wastes in civil engineering