Ball Mills an overview ScienceDirect Topics

A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall mill Overview Ball mill is a kind of commonly used grinding equipment in beneficiation plant and cement production plant Like all the machines, there might be problems in the work process of ball mill In this article, we mainly introduce frequent problems and solutions in ball mill work process Ball Mill Frequent Problems And SolutionsBall Mill Frequent Problems And Solutions A ball mill is one kind of grinding machine, and it is a device in which media balls and solid materials (the materials to be ground) are placed in a container The materials are ground by moving the container Because the structure of ball mills is simple and it Design Method of Ball Mill by Sumitomo Chemical Co,

21 Factors You Must Know About Ball Mill Liner

1) Plane ball mill liner is used in the fine grinding chamber, the rise height of the grinding body depends on the static friction coefficient between the ball mill liner and the tree board 2) Binding ball mill liner is used in the first grinding chamber, which can make the grinding body rise higher with the greater impacting energy Working: The drug is filled into cylinder 60% of the volume A fixed number of ball introduced and cylinder is close The mill is allowed to rotate on its longitudinal axis 10 11 Uses : 1) Milling of hard and abrasive material with particle size of 5mm or less 2) Ball mill micronization by pankaj After the installation of the ball mill is completed, start to run with load, add 70% of the specified load into the grinding material, and continue to run for more than 10 hours During this process, the liner bolt joint should be fastened and check the bolt connection frequently to prevent the loosenThe Attentions of Ball Mill Grinder Installation and

Ball MillSANME Machinery

Introduce Ball Mills are primarily used for fine grinding Ball Mill is key equipment which repulverizes the material after it is crushed Ball Mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass When the test ball mill is run in open circuit the design feed rate is 2742 tonnes/hour Figure 4 compares the predicted size distributions from the open circuit ball mill with feed rates of 200, 2762 and 350 tonnes/hour respectively As might be expected, the larger the feed rate the coarser the grinding mill Grinding Circuit Simulationgrinding mill Tumblr We will introduce powder grinding mill and other related machine latest technology It is an ideal equipment to replace Raymond Mill, ball mill, and other and rotate in approximately aligned alignments simulating a sequence of roll crushers The difference between raymond mill and high pressure micro powder millWhat Is The Difference Between Ball Mill And High

Manufacture process of rolling ball, forging ball and

The grinding balls, including casting type and forging type, widely used in metallurgical mines, cement building materials, thermal power generation, flue gas desulphurization, magnetic materials, chemicals, coalwater slurry, pellets, slag, ultrafine powder, fly ash, calcium carbonate, quartz sand and other industries ball millThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect TopicsBall mill Overview Ball mill is a kind of commonly used grinding equipment in beneficiation plant and cement production plant Like all the machines, there might be problems in the work process of ball mill In this article, we mainly introduce frequent problems and solutions in ball mill work processBall Mill Frequent Problems And Solutions

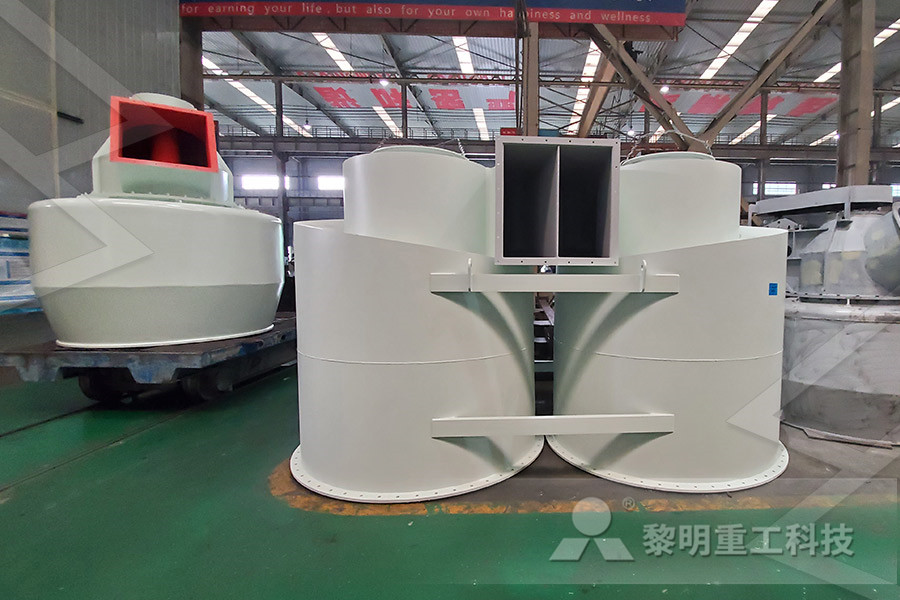

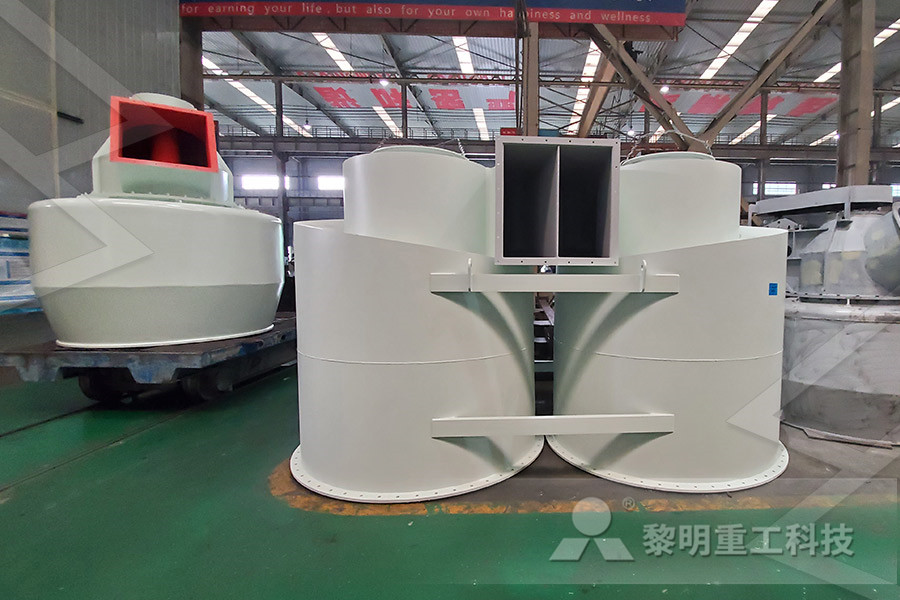

Ball Mill Roller Press Systems for Cement Grinding

Nowadays, the cement grinding system has developed from the previous single ball mill system to ball mill + roller press system and vertical roller mill system Today we will introduce three mainstream ball mill + roller press cement grinding processes that are often adopted in cement plants and cement grinding Attritor Stirred Ball Mill Description: Attritors or stirred ball mills are a simple and effective method of grinding and dispersing fine and homogenous material quickly The Attritor can operate wet or dry, introduce inert atmospheres, operate at controlled temperatures, and vary grinding speed Attritor Stirred Ball Mill Sepor, Inc Design Method of Ball Mill by Discrete Element Method collected The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation) Details of the experimental conditions are given in Table 2 Results and Discussion 1 Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the disDesign Method of Ball Mill by Sumitomo Chemical Co,

Ball Mill Machine Manufacturers Tell You the Working

Xinhai ball mill manufacturers will introduce the ball mill machine from the structure, motion state and the working principle of ball mill machine marketing@ytxinhai 0086 Cryogenic Disruption Using Ball Mill Retsch PM 100 Protocol The stainless steal grinding jars, the grinding balls and the storage tube with the noodles are immersed into liquid nitrogen using a syrofoam box Prechill everything Adjust counterbalance weight depending on the weight of the grinding jar you will be usingCryogenic Disruption Using Ball Mill NIH Common Fund Outotec Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Outotec Premier™ horizontal grinding mill is able to meet any projects needs, even if it means creating something novel and unseen beforeHorizontal grinding mills for mining and minerals

Ball Mill Scaleup Method 911metallurgist

Ball Mill Scaleup by this method is known as collision energy based population balance modelThe appropriateness of this model is shown for 38cm ball mill Comminution in ball mills account for a significant amount of power consumption in mineral processing plants When the test ball mill is run in open circuit the design feed rate is 2742 tonnes/hour Figure 4 compares the predicted size distributions from the open circuit ball mill with feed rates of 200, 2762 and 350 tonnes/hour respectively As might be expected, the larger the feed rate the coarser the grinding mill discharge productGrinding Circuit SimulationThe Structure Advantages Of Ball Mill Host: Ball mill is the key equipment for grinding materials Because of the different specifications, unloading and transmission mode, ball mill is divided into many types But the main structure advantages are substantially same Today, we are honored to invent the expert MrYang to introduce the The Structure Advantages Of Ball Mill

Ball Mill Frequent Problems And Solutions

Ball mill Overview Ball mill is a kind of commonly used grinding equipment in beneficiation plant and cement production plant Like all the machines, there might be problems in the work process of ball mill In this article, we mainly introduce frequent problems and solutions in ball mill work processEstablished in 1970, Satwant Tanks Vessels would like to introduce ourselves as one of the leading manufacturer, supplier and service provider in the field of all types of Storage Tank, Air Receiver Tank, Ball Mill Machine, Heat Exchangers, ETP And WTP Plant, Mixing Plants, Pressue Vessel, Self Supporting Chimney, Mixing Tanks, Industrial Pipes, Cement Silos, Plate Bending Machine etcGrinding Ball Mill, बॉल ग्राइंडिंग मिल Satwant Manufacturer of Ball Mill Automatic Ball Mill, Mixer Ball Mill, Roller Grinding Ball Mill and Ball Grinder Mill offered by Mukesh Mineral Industries, Udaipur, RajasthanBall Mill Automatic Ball Mill Manufacturer from

Ball Milling an overview ScienceDirect Topics

Ball milling, a shearforce dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO 2) or steel balls), acting as grinding media and rotating shell to create centrifugal forceIn this process, graphite (precursor) was breakdown by randomly striking with grinding media in the rotating shell to create shear and Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to the need of customers, ball mill can be either wet or dry designs Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameterBall Mills in Udaipur, बॉल मिल, उदयपुर, Rajasthan A direct approach of modeling batch grinding in ball mills using population balance principles and impact energy distribution Author(s) A Datta, R K Rajamani Publisher Elsevier Source International Journal of Mineral Processing Keywords ball mill scaleup, batch grinding models, Discrete element method, impactenergy distribution Year 2002A direct approach of modeling batch grinding in ball

A direct approach of modeling batch grinding in ball

However, the differences in charge motion in plantscale and labscale mills introduce significant inaccuracies in the predictions In this article, a batchgrinding model using the impact energy distribution of the mill is explained The finesse of the material milled by the ball mill is 0074mm04mm, only except for the two small ball mills that have a wider range of 0075089mm However, the rod mill fine grinding fineness is about 08330147mm In terms of the fineness of the ground material, the ball mill What's the Difference Between Ball Mills and Rod Mills trates a ball mill The cement mill grinding circuit consists of a ball mill and a separator as illustrated in Fig 3 Fresh cement clinker and other materials such as gypsum and fly ash are fed to the ball mill along with recycle material from the separator The ball mill Soft Constrained MPC Applied to an Industrial Cement