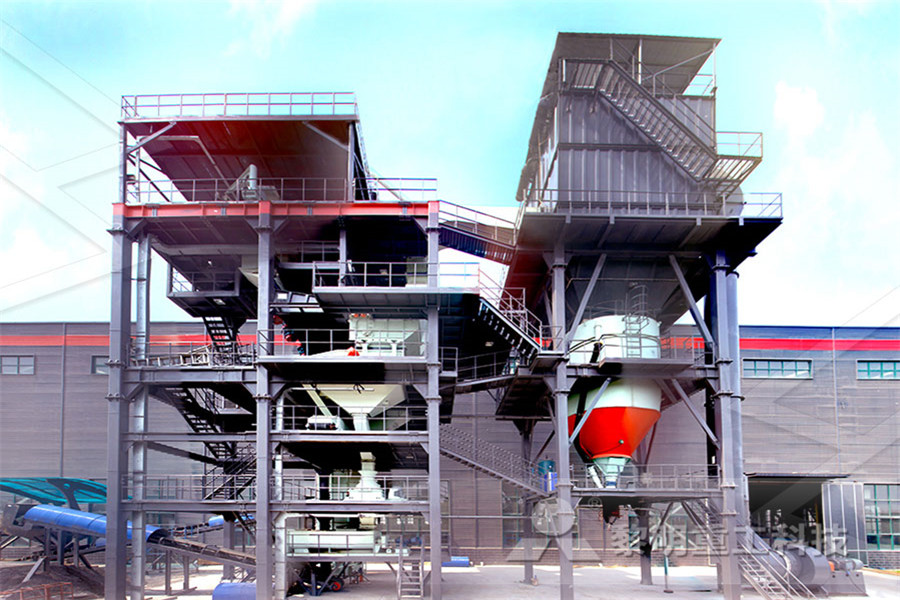

Tube Coal Mill Hongsheng Machine Building Co, Ltd

19 行 Working principle Tube Coal Mill is driven by a motor via a pin coupling, a spur gear speed reducer, and an open gear reduction drive to drive the rotating part of the mill to rotate in a simplified manner The grinding machine is equipped with a ball of grinding Ball tube mills Aerated ball tube mills are designed for anthracites, coal, lignite, shale and other materials grinding up to pulverized condition and for continuous operation in coal pulverization systems at thermal power plants and other branches of industry The coal grinding process in aerated mills is performed simultaneously with coal drying Ball tube mills Tyazhmash Figure 2 Tube Ball Mill Structure II MATHEMATICAL MODEL OF TUBEBALL MILL The procedure for coal mill modelling can be broken down into the following steps: 1) ΔTo derive the basic mill model dynamic equations through analyzing the milling process, applying physics and engineering principles and integrating the knowledge of experienced engineersDevelopment of a Tubeball Coal Mill Mathematical

ball and tube coal mill balls performance

Ball And Tube Coal Mill Balls Performance Crusher Media In Ball Tube Coal Mill Pulverizer Wikipedia The ball and tube mills are low speed machines that grind the coal with steel balls in a rotating horizontal cylinder Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is Bottom price Zirconia Ball Mill Coal vertical mill – BBMG JGM2113 coal mill is the medium speed roller type coal mill Its pulverizing parts constitute a rotating ring and 3 grinding rollers that roll along the grinding ring, and the rollers are fixed and each can revolves on its axisChina Ball And Tube Mills Manufacturers and Factory ball and tube pulverizer vibration ball and tube mill pulverizer Ball Tube Mills Coal Pulverizers with the base capacity of a pulverizer is a function of cause vibration Raw coal that is Vertical Coal Ball Mill DesignCoal Grinding Mill ball and tube pulverizer vibration is manufactured from Shanghai vibration in ball and tube coal mill teczowezaciszepl

Ball MillBall And Tube Coal Mill Power Consumption

Ball And Tube Coal Mill Power Consumption Direct injection of premilled biomass into the existing coal firing system and drax power station uk conversion of two large vertical attempts to date to convert large ball and tube coal mills to get price ball tube coal mill 10 sep 2012 2 similar to the ring and ball mill this mill uses large tires to crush the coal The four most common types of coal pulverizers are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it Impact MillsCoal Pulverizer Pall ADVANTAGES ADVANTAGES DISADVANTAGESDISADVANTAGES • ADVANTAGES:ADVANTAGES: • 1: high output up to 50 tones per hour1: high output up to 50 tones per hour • 2: No maintenance over a long periods2: No maintenance over a long periods • 3: no mill rejects, no problems with tramp iron3: no mill Ball tube mill SlideShare

Dynamic steam inerting system for a ball tube mill

The greater use of western subbituminous coals (with their higher tendency for spontaneous ignition) is a contributing factor to the increased frequency of coal pulverizer explosions The gre Dynamic steam inerting system for a ball tube mill pulverizing subbituminous coal SpringerLink Tubeball mill is another dominant type of coal mill apart from Vertical Spindle mill in industry Compared with the Vertical Spindle mills, Tubeball mills have a much higher grinding capacity However, there are fewer literatures found in studying Tubeball mill operation compared with the Vertical Spindle mill Ma et alA new modelbased approach for power plant Tubeball With this motto in mind, we've got become among essentially the most technologically innovative, costefficient, and pricecompetitive manufacturers for Ball And Tube Mills, Folded Steel Channel, Old Porcelain Electrical Insulator, Ball Mill Grinder, Normally to the majority of business users and traders to offer best quality goods and excellent companyChina Ball And Tube Mills Manufacturers and Factory

Aerodynamic Resistance of a BallTube Mill During

Analysis of experimental data on aerodynamic resistance of a balltube mill is given It is shown that this resistance has two components brought about by the pressure losses resulting from the injection of dust particles into the main flow after coal grinding and from the transport of homogeneous gas suspension flow A dimensionless equation has been obtained for the dependence of the Implement additional correction to mill PA/Fuel Flow curve if necessary based upon mill response tests Additional Program Components for Ball Tube Mills: Inspection includes liners, inlet outlet boxes, bypass (aux air) dampers, hot cold air dampers, rating damper, ball charge, ball classification, reject valves, and crusher/driersCoal Mill Optimization EAPCPerformance Of Ball Tube Coal Mill Bbd4772 Bbd coal mill operation stadswachthelmondNl coal crusher tube ball mill cybergav coal mill ball and tube type bbdcrusher and mill pulverizer wikipedia, the free encyclopedia hence, is the name ball tube mill these mills are also designated as bbd, where b, coal pulverising mill typ chat with sal coal mill bbd explosion get price coal ball mill explosionPerformance Of Ball Tube Coal Mill Bbd4772

Coal Pulverizer Pall

BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it Figure 1 Typical Arrangement of the Riley Ball Tube Mill System DESCRIPTION OF PULVERIZERS AND FUEL SYSTEMS Ball Tube Mill The Ball Tube Mill (BTM) is a cylindrical lowspeed grinding mill It consists of a steel barrel, lined with cast abrasionresistant liners and partially filled with hardened steel balls Coal and preheated primary airA Comparison of Three Types of Coal Pulverizers Coal mill Energy saving ball mill Intermittent ball mill Grid ball mill Steel ball coal mill Rod mill Ceramic Ball mill Tube Mill LVRM Vertical Mill Coal vertical mill Slag ball mill Roller Press Inquiry You can get the price list and we will contact you within one business day! Contact usmill equipmentBall millRod millCoal millTube Mill

Exploring ball size distribution in coal grinding mills

Tube mills use steel balls as grinding media Due to wear in the abrasive environment it is necessary to charge new balls periodically to maintain a steady balanced ball charge in the mill The amount and ball size distribution in this charge, as well as the frequency with which new balls are added to the mill, have significant effects on the appropriate detection methods for coal mills Each generating unit at Merom has three Riley Power doubleended ball tube mills The mills can each provide 65 tph of pulverised coal to the boiler, a total of 195 tph per boiler NFPA Annex K5 Coal Firing General Considerations states: “It takes as little as 14 kg of pulverised coal in 283 m3 COAL MILL Land Instruments InternationalCiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): Abstract 1 This paper presents a mathematical model for Tubeball mills which is developed based on the previous work The Particle Swarm Optimization (PSO) method is used to identify the unknown parameters of the coal mill model with the online measurement data provided by EDF EnergyCiteSeerX — Development of a Tubeball Coal Mill

Aerodynamic Resistance of a BallTube Mill During

Analysis of experimental data on aerodynamic resistance of a balltube mill is given It is shown that this resistance has two components brought about by the pressure losses resulting from the injection of dust particles into the main flow after coal grinding and from the transport of homogeneous gas suspension flow A dimensionless equation has been obtained for the dependence of the appropriate detection methods for coal mills Each generating unit at Merom has three Riley Power doubleended ball tube mills The mills can each provide 65 tph of pulverised coal to the boiler, a total of 195 tph per boiler NFPA Annex K5 Coal Firing General Considerations states: “It takes as little as 14 kg of pulverised coal in 283 m3 COAL MILL Land Instruments InternationalPerformance Of Ball Tube Coal Mill Bbd4772 Bbd coal mill operation stadswachthelmondNl coal crusher tube ball mill cybergav coal mill ball and tube type bbdcrusher and mill pulverizer wikipedia, the free encyclopedia hence, is the name ball tube mill these mills are also designated as bbd, where b, coal pulverising mill typ chat with sal coal mill bbd explosion get price coal ball mill explosionPerformance Of Ball Tube Coal Mill Bbd4772

BHEL HYDERABAD :: Product Profile

BALL TUBE MILL: T he Ball Tube Mill is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter Type Ball tube mills Bowl Mill Ball race Mill Hammer mill, beater mill or fan mill Dominating Principal Attrition Crushing Impact 15 Tube mill Maximum mill Capacity vs coal moisture at coal HGI 100110 and PF Fineness of 70 % passing through 200 Mesh 3500 3600 3700 3800 3900 4000Pulverizer Plant OM Aspects The Kennedy Airswept Tube Mill uses air to remove the pulverized coal leaving behind the larger particles that need additional puliverizing ADDITIONAL INFORMATION: [From "Marine Development of Pulverized Coal" by Comdr J S Evans and RC Brierly, page 407] The Mercer is a 9500ton cargo vessel built by the Federal Shipbuilding Co at PULVERIZING BALL FROM KENNEDYVAN SAUN AIR

MBY Industrial helical ball mill gearbox fair price for

MBY Ball Mill Gearbox MODEL: MBY400、MBY450、MBY500、MBY560、MBY630、MBY710、MBY800、MBY900、MBY1000、MBY1100 RATIO: 1:4 1:45 1:5 1:56 1:63 1:71 Description For side drive device of tube mill, we specially configures highperforming MBY (MBYX) gearboxes as the primary gearboxManufacturer of BALL MILL GIRTH GEAR PINION END COVER ASSEMBLY Ball Mill Girth Gear PINION, Cement Plant Girth Gear Large Ring Gear Cement Kiln, Kiln Girth Gear offered by Piyali Engineering Corporation, New Delhi, Delhi Nozzle, Kiln Shell, Feed Tube, Flange, Bimetallics Segments, Coal Injector, Thermowel, Protection Tube, Swirler BALL MILL GIRTH GEAR PINION END COVER 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner Coal mill pulverizer in thermal power plants