Vertical Shaft Impact Crusher GEP Ecotech

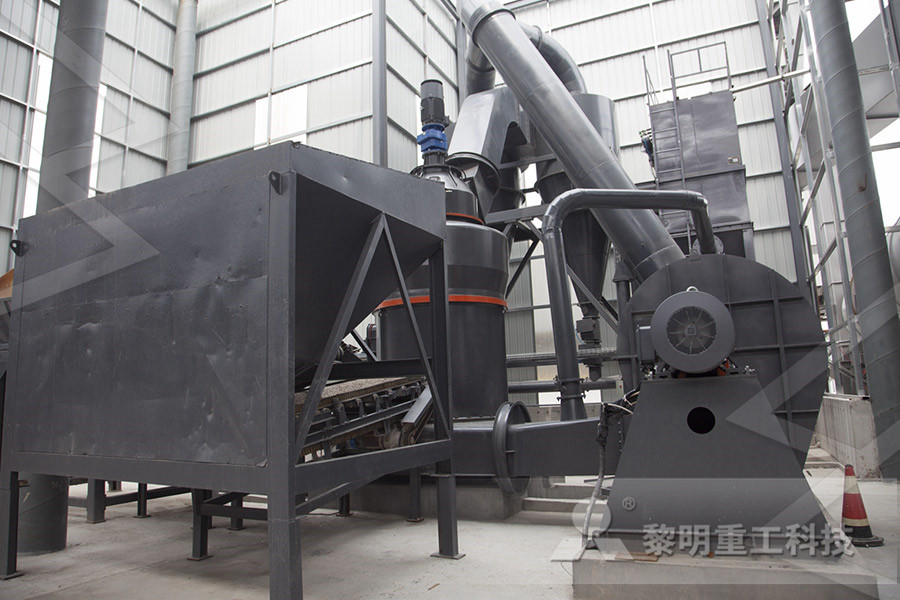

Working Principle The vertical shaft impact crusher combines two crushing modes, stone to stone and stone to iron, and can crush hard materials such as concrete and waste bricks in construction and renovation waste to very small sizes, usually for secondary or tertiary fine crushing, and has a shaping function, the finished product is mostly in cubic shape, with low flake content, ready for Alibaba offers 3,049 vertical shaft impact crusher part products A wide variety of vertical shaft impact crusher part options are available to you, such as material, applicable industries, and warrantyvertical shaft impact crusher part, vertical shaft impact The vertical shaft impact crusher is a common manufactured sand making equipment The Camelway ZS series vertical shaft impact crusher is favored by the market for its significant advantages such as large feed size, high sand formation rate, low wear and low energy consumption At the same timeVertical Shaft Impact Crusher, VSI Sand Making

Vertical Shaft Impact Crusher AF Minerals Equipment

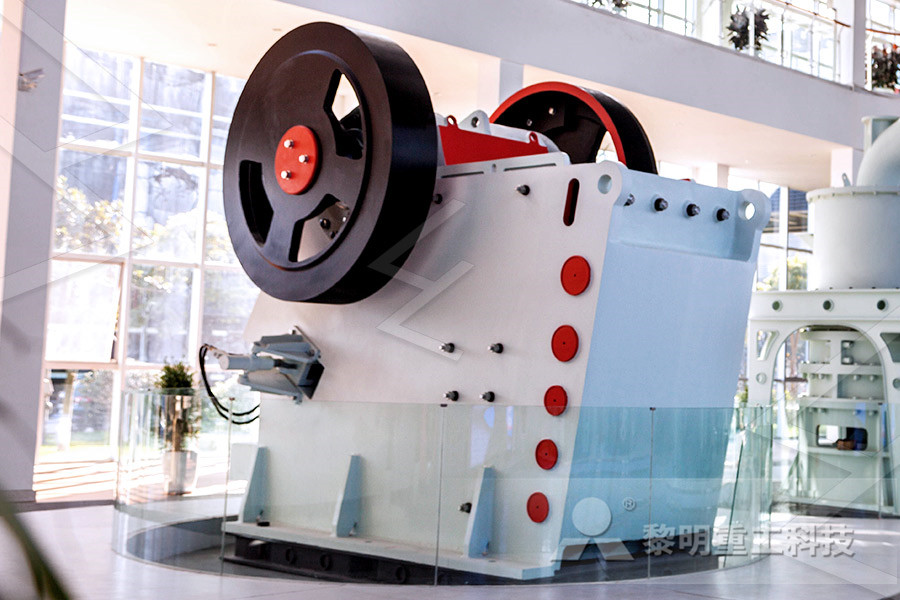

AF Minerals Equipment in Rowland Heights, CA is your source for topoftheline vertical shaft impact crushers They are widely used for quaternary, tertiary, and secondary applications of crushing rock, cement clinker, quartzite, concrete aggregate, and more Connect with us today to learn moreThe main spare parts in vertical shaft impact crusher (sand making machine) are feeder hopper, raw material screen, crushing cavity, impeller, bearing, transmission shaft and so on Among them, transmission shaft and bearing mainly transport power, impeller and crushing cavity are the main parts to process raw materialSpare Parts in Vertical Shaft Impact Crusher Abstract: In this paper, a new rotor with two impact in the vertical shaft impact crusher is analyzed, an effect of the angle at the guide device thrown materials on the velocity that material reach the impact plate and rebound to a anvil in the crushing chamber are discussed three mass ejection Angle are simulated by discrete element software EDEM, and the result shows that effect of two Vertical Shaft Impact Crusher

Vertical Shaft Impact Crusher Wear Theory Research

Using the impact crusher vertical shaft rotor rotating speed, the vertical shaft impact crusher work the impact of the speed and impact, can improve the crusher of broken ability and production efficiency The vertical shaft impact crusher the materials in the parts of the impact of the crusher collision effect, can effectively reduce the wear and tear of the machine Nesans CF Series Vertical Shaft Impact Crusher are high impact force, tertiary stage, high output ratio crushers Uniquely designed to achieve the required product gradation for the production of msand With dynamically balanced rotor design and robust rotor tips, CF Series Vertical Shaft Impact Crusher can save a huge on your maintenance costsVSI Crusher Nesans Mining and Automation Private The PFR series of Impact crushers are a perfect combination of heavy duty rotor, high wearresistant materials which are incorporated in the complete high quality, steel fabricated crusher frame and chamber design This combination has proven to be extremely successful over a long period of time, not only increasing productivity and product quality but also reducing production wear part costsHorizontal Vertical shaft Impact Crushers Moore

Barmac® B Series™ impact crushers Outotec

Barmac® vertical shaft impact (VSI) crushers were the first vertical shaft impactors in the world The original Barmac® was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globeIntroduction Advantages NFLG vertical shaft impact crusher adopts the centrifugal extractor hammer broken way, through the principle of "stone hit stone", the implementation of the rotor into the crusher for crushing, grinding and shaping raw materials, implement a born broken, to a large particle materials one time (or recycle) broken and shaping, significantly improve grain shape, very Vertical Shaft Impact CrusherNFLG China Working Principle The vertical shaft impact crusher combines two crushing modes, stone to stone and stone to iron, and can crush hard materials such as concrete and waste bricks in construction and renovation waste to very small sizes, usually for secondary or tertiary fine crushing, and has a shaping function, the finished product is mostly in cubic shape, with low flake content, ready for Vertical Shaft Impact Crusher GEP Ecotech

Vertical Shaft Impact Crusher AF Minerals Equipment

AF Minerals Equipment in Rowland Heights, CA is your source for topoftheline vertical shaft impact crushers They are widely used for quaternary, tertiary, and secondary applications of crushing rock, cement clinker, quartzite, concrete aggregate, and more Connect with us today to learn moreAbstract: In this paper, a new rotor with two impact in the vertical shaft impact crusher is analyzed, an effect of the angle at the guide device thrown materials on the velocity that material reach the impact plate and rebound to a anvil in the crushing chamber are discussed three mass ejection Angle are simulated by discrete element software EDEM, and the result shows that effect of two Vertical Shaft Impact Crusher EXCEPTIONAL MINERALS BENEFICIATION CAPABILITIES Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, wellformed aggregates and industrial minerals Advanced alternatives with open table designs, multiport rotor MEKA NEW VERTICAL SHAFT IMPACT CRUSHERS

Vertical Shaft Impact CrusherSANME

VC7 Series Vertical Shaft Impact Crusher is a new sand maker, which is highfunctioned equipment for making sand and shaping, is researched and produced by our corporation, absorbed with the advanced technology from Germany, and owned advanced world standards This equipment has two types: rockonrock and rockoniron time Other than that, the strength of the concrete can be determined by counting the number and the percentage of good quality of aggregate being used Keyword: Rock Vertical Shaft Impact Crusher (RoR VSI); Local Database System; System Performance; Shape Breakdown 1Introduction The Granite and the Limestone are still remained theIntelligent Rock Vertical Shaft Impact Crusher Local CHPL series verticalshaft impact crusher employs thin oil lubrication system, providing excellent bearing work environment so as to gain higher stability and longer service life A variety of safety tests, two control modes and multi safety protection ensure verticalshaft impact CHPL Verticalshaft Impact Crusher Series Zhejiang

Barmac® B Series™ impact crushers Outotec

Barmac® vertical shaft impact (VSI) crushers were the first vertical shaft impactors in the world The original Barmac® was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globeBarmac® B6150SE™ is a vertical shaft impact (VSI) crusher It produces highquality cubical end products and is ideal for the last crushing Known for low operating costs, Barmac® is often utilized in producing highquality aggregates, sand, material for heap leaching, pregrinding and finished industrial minerals productsBarmac® B6150SE™ impact crusher OutotecVERTICAL SHAFT IMPACT CRUSHER cooling system ensures normal operation in constant temperature and maintains the best conditions at which the core parts are running thus prolonging its service life Scientific protecting mechanism can monitor the service data such as oil temperature and oil pressure in real time 2 Advanced working VERTICAL SHAFT IMPACT CRUSHER Crusher Spares

Vertical Shaft Impact Crusher GEP Ecotech

Working Principle The vertical shaft impact crusher combines two crushing modes, stone to stone and stone to iron, and can crush hard materials such as concrete and waste bricks in construction and renovation waste to very small sizes, usually for secondary or tertiary fine crushing, and has a shaping function, the finished product is mostly in cubic shape, with low flake content, ready for The vertical shaft impact crusher is the most common cement engineering use of sand mechanism equipment In the process of production, the quality of the finished product and sand fineness modulus whether meet the requirements of the end, most of them are according to human experience or by drying, screening, weighing and sampling methods such Vertical Shaft Impact Crusher The vertical shaft impact crusher is a common manufactured sand making equipment The Camelway ZS series vertical shaft impact crusher is favored by the market for its significant advantages such as large feed size, high sand formation rate, low wear and low energy consumption At the same time, this sand making machine has several functions of crushing, sand making and shapingVertical Shaft Impact Crusher, VSI Sand Making

Vertical Shaft Impact Crusher,Sand Machine,Primary

VC Series Vertical Shaft Impact Crusher is Product Development (Sand Making Machine) Engineer combined gravel plants customers over the years using traditional sand making machine problems encountered Professional R D of a new sand shaping equipmentVC sand making machine equipment with reliable performance, reasonable design, convenient operation, high CHPL series verticalshaft impact crusher employs thin oil lubrication system, providing excellent bearing work environment so as to gain higher stability and longer service life A variety of safety tests, two control modes and multi safety protection ensure verticalshaft impact CHPL Verticalshaft Impact Crusher Series Zhejiang Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial mineralsVertical Shaft Impact Crushers MEKA Crushing

Ingenuity: Meilan Mining Machine ML Series Vertical

The new ML series vertical shaft impact crusher developed and produced by Meilan is the result of our pursuit of perfection The company's RD team conducted rigorous demonstration and analysis of all necessary components through finite element analysis, establishing mathematical models, and simulating the actual application environment, thereby achieving extremely efficient design A system and method for monitoring a vertical shaft impact crusher comprises a plurality of sensors which continuously monitor the current status of a plurality of crusher component parts, a computer in communication with the sensors, and a graphical user interface in communication with the computer and on which is displayed a plurality of virtual instrumentsSystem and method for monitoring a vertical shaft Ecoman, one of India’s most preferred Vertical Shaft Impactors manufacturers and exporters of eminent artificial and msand fabrication machines has been serving various industrial verticals since its inception, leaving a mark of excellence in the market With extremely beneficial features of its impact crushers, Ecoman makes it pretty simple to cut down large rocks in to small size gravelsEcoman Vertical Shaft Impactors, Ecoman ID: