The Most Valuable Things You Need to Know about

Secondary gypsum crushing equipment price: Get Latest Price Gypsum grinding process The crushed gypsum is sent to a ball mill for grinding until 90% of it is less than 149 μm (100 mesh) The ground gypsum powder leaves the mill in the form of airflow and is collected in the cyclone separator The process of grinding Ball mill Compression Molding of Gypsum Blocks Using Ecological Brick Machines Ana Cecilia Vieira da Nóbrega1,a, Germano Gomes Leite2,b, Humberto Correia Lima Júnior1,c, Normando Perazzo Barbosa3,d and Ulisses Targino Bezerra4,e 1UFPE, Pernambuco, Brazil 2IFPE, Pernambuco, Brazil 3UFPB, João Pessoa, Brazil 4IFPB, João Pessoa, Brazil , Compression Molding of Gypsum Blocks Using Ecological Compacting machine Gypsum is a kind of material which is hard to be directly briquette Lots of the air/gap between the raw material particles makes them hard to form together, by using a compacting machine (density adding machine), most of the air/gap will be Gypsum briquette machine – how to set up a gypsum

Preparation of specific gypsum with advanced

1 Introduction Gypsum (CaSO 4 2H 2 O) is one of the oldest inorganic materials and has been widely used in buildings and constructions , , , , Conventional gypsum products are generally produced by a casting process Bassanite (“plaster of Paris”, calcium sulfate hemihydrate, CaSO 4 05H 2 O) is mixed with water, casted and then hydrated into gypsum (calcium sulfate dihydrate, CaSO The melting process of copper alloy with the main composition of 60% copper and 38% zinc was carried out using a gas fired furnace Graphite crucible had been used and the furnace firing was controlled by a valve in the gas piping The melting process took about 45 minutes After the molten metal reached the pouring temperature, slag wasPOROSITY AND STRENGTH PROPERTIES OF GYPSUM To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock Next the calcined gypsum is mixed with water and additives to form a slurry which is fed between continuous layers of recycled paper on a long board machineMaking Gypsum Board – Gypsum Association

gypsum Michigan State University

Gypsum deposits are located in the center of the Michigan basin It is only mined at places where the gypsum is near the surface, while at others it is buried by more than 1200 feet of rock (see map below) Gypsum beds are seldom more than 20 feet in thickness production of gypsumgrade paperboard and gypsum wallboard has always been On November 27, 1999, Republic Paperboard Company, Lawton, Oklahoma, USA, brought about a revolution in paper manufacturing: A new gypsumgrade paperboard machine was brought online – the world’s first paper machine with two gap formers This milestone inPaper Technology Journal VoithGypsum is a relatively common mineral that is widely available in agricultural areas and has a number of specialized agronomic uses, principally as a Ca source on legumes and as a soil conditioner on sodic soils Recent research has suggest that the utility of gypsum may extend to a greater range of soils and crops than previously acknowledgedUse of Gypsum on Soils: A Review SpringerLink

What is 3D Printing How Do 3D Printers Work? A

This is a process requiring the use of two different materials: a powder material (gypsum plaster, starch, etc) that sits on a print bed, along with a binding ink which is ejected from a nozzle Make gypsum based machine stucco plaster needs some chemical materials that are beta gypsum, slaked lime,calcite,silica sand using for filler, sodium lauryl sulfate using for air entrainment agent, starch ether using for thickness and holding water inside, methyl cellulose or hydroxyethyl cellulose using for thickness of mixture and citric acid using for adjusting of PH mixture and etcProduction Process of Gypsum Machine Stucco Plaster Gypsum Ceiling Installation using the LESSER LEVEL MACHINE Step 3: Metal Framing Install two layers of metal studs, the first layer should run from channel to channel to create a 600mm centers between studs The second layer should run on top of the first layer as a support structure Make sure you interconnect the stud frame with gypsum screwsGypsum Ceiling Boards Installation Process » Gypsum

The Gypsum Mining Process Composition Essays

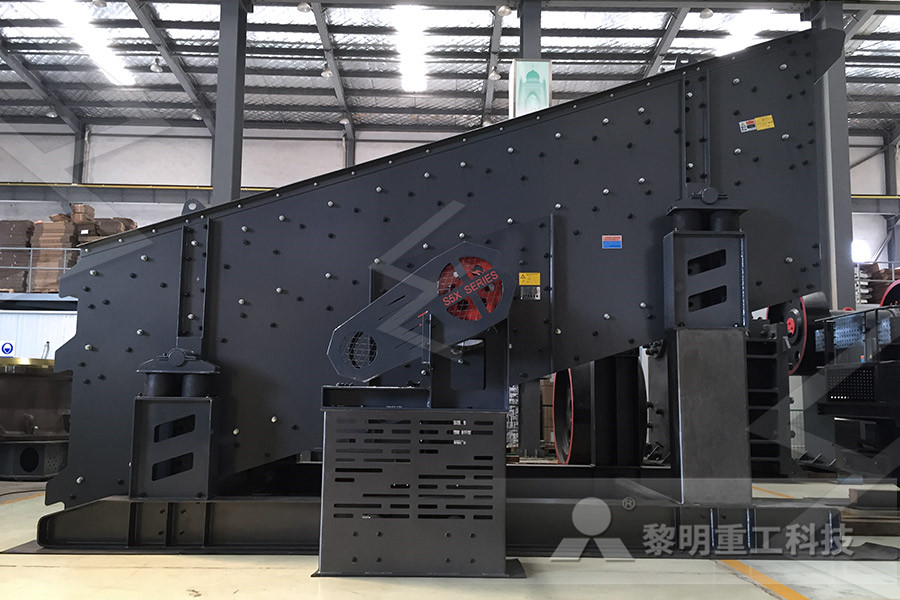

For those gypsum powder producers, using efficient gypsum powder processing machine can ensure them to stand the test of market and quality Based on the gypsum mining process, gypsum powder processing machines can be divided into the jaw crusher, grinding mill, vibrating feeder, vibrating screen, and drierJet gips – Machine applied gypsum plastering – Makina sıva alçısı – Iran gypsum plaster espandar company perlitli makina sıva alçısı This is used in interior plastering for all walls and ceilings and is characterized by its whiteness, thermal insulation Moistureproof, and fireresistanceMachine applied gypsum plastering jet gips Gypsum plasterboard production process flow chart: ,through the 1#horizontal machien to turn,after that,the two gypsum boards leave the 1#horizontal machine at the same time,then using the closer roller to make the space between two plates meet the requirements,through the distribution machine into the drier for drying gypsum board line,payper surface gypsum board line

Process for preparing calcined gypsum and gypsum

An improved process for manufacturing gypsum board characterized by improved handling properties and decreased surface area of the treated calcium sulfate hemihydrate stucco and by using a reduced amount of water to fluidize the treated stucco in forming a slurry which is fed to a board making machine which comprises: The process of producing gypsum products from rock to room is fascinating With mining operations dating back to 1876, British Gypsum now operates three gypsum mines across the UK that specifically support the manufacturing of plaster “Once we’ve extracted the gypsum from the mine using a continuous mining machine, we must crush it The production of plaster Professional Builder Furthermore, most of the papers that reuse gypsum waste as a substitute of commercial one used a 100% substitution ratio This study analyses several substitution ratios (25%, 50%, 75% and 100%) for each type of gypsum waste and heating process 2 Materials and methods21 Gypsum powder wastes under analysis and heating processesInfluence of the heating process on the use of gypsum

EPA2 Gypsum board and process of

A gypsum board includes a set gypsum core and front and rear paper facers adhered thereto At least the front paper facer has substantially isotropic tensile strength, thereby providing the gypsum board with enhanced nail pull resistance A process for manufacturing such gypsum board is further provided production of gypsumgrade paperboard and gypsum wallboard has always been On November 27, 1999, Republic Paperboard Company, Lawton, Oklahoma, USA, brought about a revolution in paper manufacturing: A new gypsumgrade paperboard machine was brought online – the world’s first paper machine with two gap formers This milestone inPaper Technology Journal Voithplaster of paris gypsum powder making machinery Products Gypsum powder production line works based on the following process: The Crusher will break the bigsize gypsum ore into small 25mm pieces, and then the small pieces will be sent to the grinder, after grinding fine, the qualified raw gypsum powder will be sent to boiling furnace to calcine, and the unqualified part will be sent to gypsum manufacturing machinery and process

gypsum manufacturing machinery and process

gypsum cement manufacturing process Panola Heavy gypsum cement manufacturing process,Gypsum is a mineral and is hydrated calcium sulfate in chemical form Gypsum plays a very important role in controlling the rate of hardening of the cement During the cement manufacturing process upon the cooling of clinker How Gypsum is Made Editor’s Note: The following article is based on information supplied by Gold Bond It describes Gold Bond’s manufacturing process Other gypsum manufacturers may differ in certain characteristics from the process described below Chemists call it CaSO 42H 2O It’s found in the pyramids of Egypt as wellHow Gypsum is Made AWCIGypsum Ceiling Installation using the LESSER LEVEL MACHINE Step 3: Metal Framing Install two layers of metal studs, the first layer should run from channel to channel to create a 600mm centers between studs The second layer should run on top of the first layer as a support structure Make sure you interconnect the stud frame with gypsum screwsGypsum Ceiling Boards Installation Process » Gypsum

Gypsum Powder Making Machine of Gypsum Powder

Gypsum Powder Making Machine Capacity: 20,000 t/y~300,000 t/y Automation: Fully automatic Calcination system: Using ebullition furnace to calcine, adopting heat conductive oil In this process gypsum is crushed, dried, ground, and calcined Not all of the operations shown in Figure 11161 are performed at all gypsum plants Some plants the process of making gypsum powder crusher The Process Of Making Gypsum Powder Manganese Crusher the process of making gypsum powder to find your need what is the process of making gypsum ceiling For those gypsum powder producers, using efficient gypsum powder processing machine can ensure them to stand the test of market and quality Based on the gypsum mining process, gypsum powder processing machines can be divided into the jaw crusher, grinding mill, vibrating feeder, vibrating screen, and drierThe Gypsum Mining Process Composition Essays

Gypsum Board Production Line With Knauf

THE COMPANY ADVANTAGE Shandong Tengfei Mechanical and Electrical Technology Co,Ltd was established in 1998 and was professional and biggest in designing and manufacturing of gypsum machinery in China we can design and manufacture and install and commission gypsum board machine,gypsum powder machine and gypsum block machine ourselvesOur gypsum board The process of producing gypsum products from rock to room is fascinating With mining operations dating back to 1876, British Gypsum now operates three gypsum mines across the UK that specifically support the manufacturing of plaster “Once we’ve extracted the gypsum from the mine using a continuous mining machine, we must crush it The production of plaster Professional Builder production of gypsumgrade paperboard and gypsum wallboard has always been On November 27, 1999, Republic Paperboard Company, Lawton, Oklahoma, USA, brought about a revolution in paper manufacturing: A new gypsumgrade paperboard machine was brought online – the world’s first paper machine with two gap formers This milestone inPaper Technology Journal Voith