Aggregate Crushing PlantHigh Safety High Efficiency

For any abnormal condition, repair and maintain in time In addition, due to the complexity of the working environment of the aggregate crushing plant, users need to clean and maintain the equipment in time after operation Semidry production means that there is no water in the section before crushing and before crushing, have high cleanliness Semidry production processes are used more in southern China In this process, sewage containing soil and stone Aggregate Crushing Plant and Processing Sand The bearing could directly affect the machine’s life and operating rate, which requires the lubricating oil that is injected in the machine must be clean, and the seal must be good The main oiling parts of the portable crushing plant : (1) Rotary bearings (2) The Installation and Maintenance of Mobile Crushing

Crushing Plant an overview ScienceDirect Topics

Consequently, both the mine and the coarseore plant should have a greater hourly capacity than the fine crushing and grinding plants, and storage reservoirs should be provided between them Ordinary mine shutdowns, expected or unexpected, will not generally exceed a 24 h duration, and ordinary coarse crushing plant repairs can be made within an equal period if a good supply of spare parts is kept on Clean end products guaranteed If you are looking for a mobile crushing plant for contracting with the ability to produce clean, precisely sized end products effectively, the new LT95S is the answer LT95S is designed to crush hard rock and any recycling materials equally effectively In addition, LT Series Crushing Plants for ContractorsQuarry crushing plant has large crushing rate, strong production capacity, easy maintenance, long service life It can provide large amount of economic profit for customers The equipment is designed for crushing limestone, basalt, silica, pebbles, granite The finished stones have uniform particle size Quarry Crusher Plant Crushing Screening Plant

Crushing Plant Design and Layout Considerations

Crushing plant design should accordingly provide for laydown and workspace for onsite equipment refurbishment and repair Where possible, equipment manufacturers should be encouraged to stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing a WINNIPEG, Manitoba, April 26 (Reuters) Agribusiness Viterra Inc VILCUL said on Monday that it will build the world's biggest canolacrushing plant at Regina, Saskatchewan, and open it in late Viterra to build new Canada canolacrushing plant by 1800 meters of conveyor associated with the planned mine crushing plant installation In addition to bearings and pillow blocks, this package includes Trelleborg shock absorbers, Iteca Socade speed sensors, Vega level switches, and Schneider limit switchesUnused Crushing Plant Support Installations Rabin

Aggregate Crushing Plant and Processing Sand

According to the production capacity requirements (rough crushing more than 1 200 t / h), the characteristics of raw materials containing more soil and the market demand for sand and gravel aggregate products, combined with the general map of the plant, the process layout, the coarse crushing equipment uses the rotary crusher go to jaw rock Complete Semi Portable Crushing Plant Previously supporting InPit Heap Leach Operation Turnkey offer has been received, finalized on March 31, 2021 Rabin is dedicated to providing a safe and clean environment for our customers facilities with idle or marginally productive assets Rabin’s operations include selling entire plants Complete Semi Portable Crushing Plant Rabin The overall crushing and screening plant includes a frame, the frame is equipped with a firststage crushing device, a screening device, and a secondstage crushing device, which can crush building aggregate, sand, granite, Cobblestone, quartzite, basalt, limestone, and other rocks, iron ore, gold ore can clean and separate the stone Crushing And Screening Plant Process Flow Video!

Quarry Crusher Plant Crushing Screening Plant

Quarry crushing plant has large crushing rate, strong production capacity, easy maintenance, long service life It can provide large amount of economic profit for customers Wide use; The equipment is designed for crushing limestone, basalt, silica, pebbles, granite The finished stones have uniform particle size and good shape Clean and Ecofriendly Production Facilities run under a closed plant, and the production goes ahead in an environmental dry process, which effectively keeps clean environment around the production site and satisfies China's strict requirements about environment protection, truly combining economic profits with environment benefits8001000TPH Limestone Crushing Plant Mobile Crushing Plant K series portable crushing and screening plants can not only be used for crushing, but also be used to produce high quality sand, wash sand, sharp aggregates and screen particles and some other processing work in metal mines, building aggregates and crusher plant, stone crusher , mining mill and grinding

The DePaul Group hiring Crushing Plant Operator in

Duties include clean up, maintenance and running the plant Qualified candidates must have knowledge of crushing, screening, conveying, maintenance, ability to lift 30lbs on a regular basis, climb NFLG tracked mobile cone crushing plant has six models In aggregate production and the application of the surface soil of the mine, it has excellent performance, good productivity and high efficiencyTracked Mobile Cone Crushing Plant Produced by Coal preparation plant is a coal processing plant that include a series of processes: raw coal screening, crushing, coal washing, separation, clean coal dewatering and slime recycling Which can separate coal from impurities, remove mineral impurities from raw coal and divide it Coal Preparation Plant Coal Preparation Process

Aggregate crushing plant operator Jobs Glassdoor

Aggregate Mining Company is seeking the ideal candidate who will operate a crushing and screening plant while maximizing material production and minimizing plant interruptions and/or breakdownsThe applicant may also be used in performing other work assignments such as cleanup and operation of mobile equipment including loaders to cover If the plant doesn’t have the resources to function 24/7, the cold weather will make starting up the plant in the morning impractical Performing winterization can be beneficial because it allows a chance to clean up, analyze, and improve a crushing plant for the next crushing seasonHow to Winterize a Crushing Plant According to the production capacity requirements (rough crushing more than 1 200 t / h), the characteristics of raw materials containing more soil and the market demand for sand and gravel aggregate products, combined with the general map of the plant, the process layout, the coarse crushing equipment uses the rotary crusher go to jaw rock Aggregate Crushing Plant and Processing Sand

Crushing Plant Operator Job in Marlborough

Duties include clean up, maintenance and running the plant Qualified candidates must have knowledge of crushing, screening, conveying, maintenance, ability to lift 30lbs on a regular basis, climb 40 ft and operate a 30 ton truck The mobile crushing plant is also known as a portable crushing plant and mobile crushing station, which is one of the most common mobile crushing equipment used in the process of crushing stone and making sand This article will answer all the questions of mobile crushing The Common Questions of Mobile Crushing Plant and Clean and Ecofriendly Production Facilities run under a closed plant, and the production goes ahead in an environmental dry process, which effectively keeps clean environment around the production site and satisfies China's strict requirements about environment protection, truly combining economic profits with environment benefits8001000TPH Limestone Crushing Plant

animal bone crushing plant: Making no bones about it

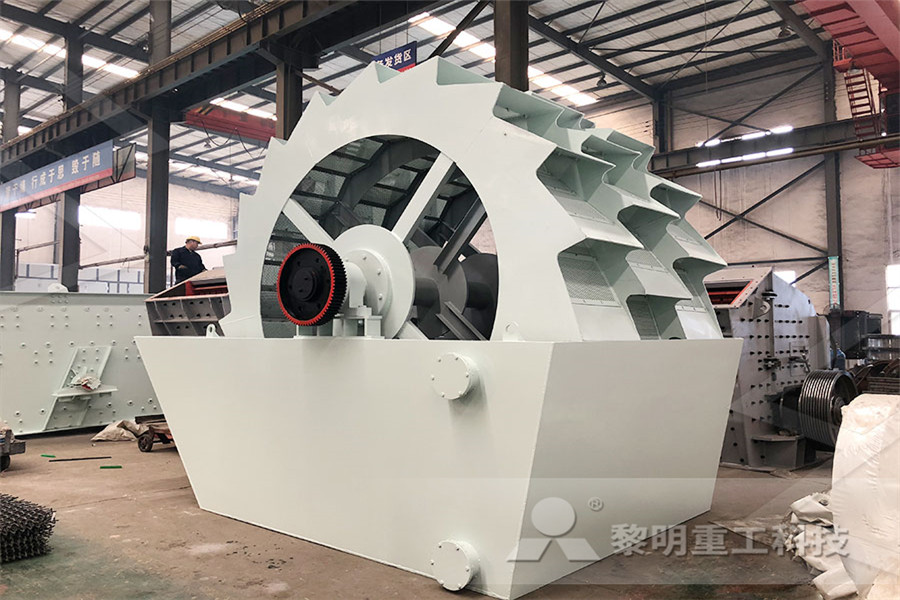

An animal bone crushing plant located in Razack Palya where carcasses were being burnt to make manure and fertilizers has been cleaned up by Karnataka State To ensure maximum efficiency from your washing plant the introduction of sand washing equipment is widely accepted as the number one choice MEKA Compact sand plants are designed for aggregate producers requiring a fines recovery plant to support their existing operations by reducing the volume of fine material reporting to the settling pondWashing Equipment MEKA Crushing Screening Coal preparation plant is a coal processing plant that include a series of processes: raw coal screening, crushing, coal washing, separation, clean coal dewatering and slime recycling Which can separate coal from impurities, remove mineral impurities from raw coal and divide it Coal Preparation Plant Coal Preparation Process

Aggregate crushing plant operator Jobs Glassdoor

Aggregate Mining Company is seeking the ideal candidate who will operate a crushing and screening plant while maximizing material production and minimizing plant interruptions and/or breakdownsThe applicant may also be used in performing other work assignments such as cleanup and operation of mobile equipment including loaders to cover A controversial Illinois coal plant that has locked municipalities across the Midwest into financially crushing contracts could be forced to close within a decade under proposed state clean Closing Illinois coal plants wouldn't end payments