Sand Aerated Concrete Equipment

THE EQUIPMENT FOR AERATED CONCRETE PRODUCING The crushed sand is used in aerated concrete producing The gypsum, cement and other additives are added to sand for the strength of the mixture Sand is crushed in the ball mills, the type of grinding is wet ball milling The steel grinding balls 2540 mm in diameter are in the millAutoclaved concrete brick,AAC Block Equipment ,brick making machine Autoclave is the key equipment in the production of aerated concrete and autoclave brick The autoclave is applicable for curing the cut body under high temperature and high pressure, and it is also applicable for curing the autoclaved brick under high temperature and high pressureaerated concrete equipment, aerated concrete The crushed sand is used in aerated concrete producing The gypsum, cement and other additives are added to sand for the strength of the mixture Sand is crushed in the ball mills, the type of grinding is wet ball milling The steel grinding balls 2540 mm in diameter are in the mill Each manufacturer has its own milling requirementsTHE EQUIPMENT FOR AERATED CONCRETE

Easy to use sand autoclave aerated concrete

This purification means that these sand autoclave aerated concrete can be used in places that are known to attract huge crowds Additionally, the sand autoclave aerated concrete have the selfchecking capability to ensures that malfunction caused by humanerror is reduced The safety measures of these pieces of equipment also make them not to have negative effects on peopleRaw material: Cement, Lime, Sand, Gypsum, Aluminum powder, Water From this page, you can get the Lime Kiln,Rotary Kiln,Aerated Concrete Equipment,Autoclave Aerated Concrete Blocks Equipment,Ball Mill,Beneficiation if you are interested in our Aerated Concrete Equipment/Autoclave Aerated Brief Introduction Aerated concrete block equipment can make concrete brick/block which is a light weight, multicell new construction material; the features include lower density, heat insulation, high strength, exceptional seismic performance, great work ability, good resistance to high temperature, maximum sound insulation and excellent adaptabilityAerated concrete block equipment Zhengyi

Aerated Concrete: Types, Advantages Disadvantages

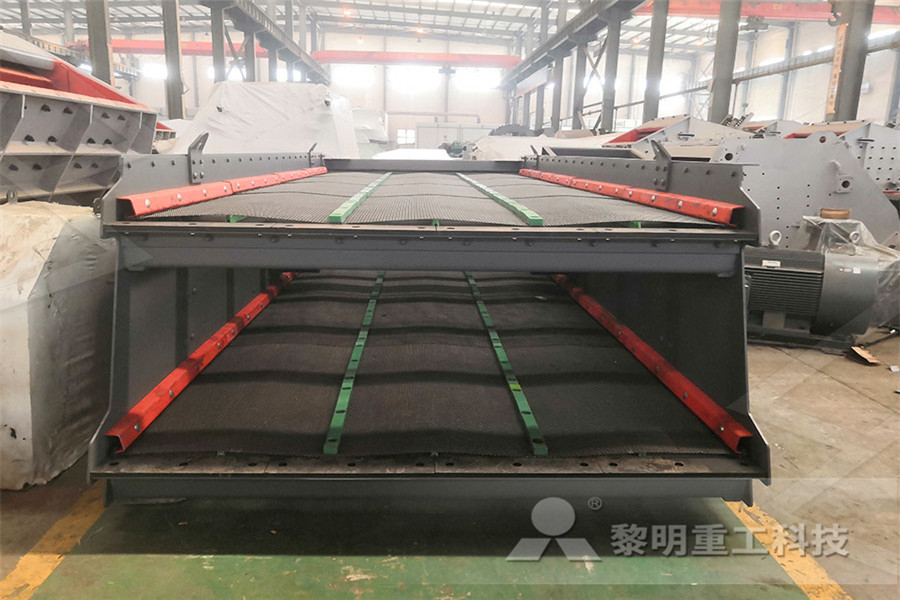

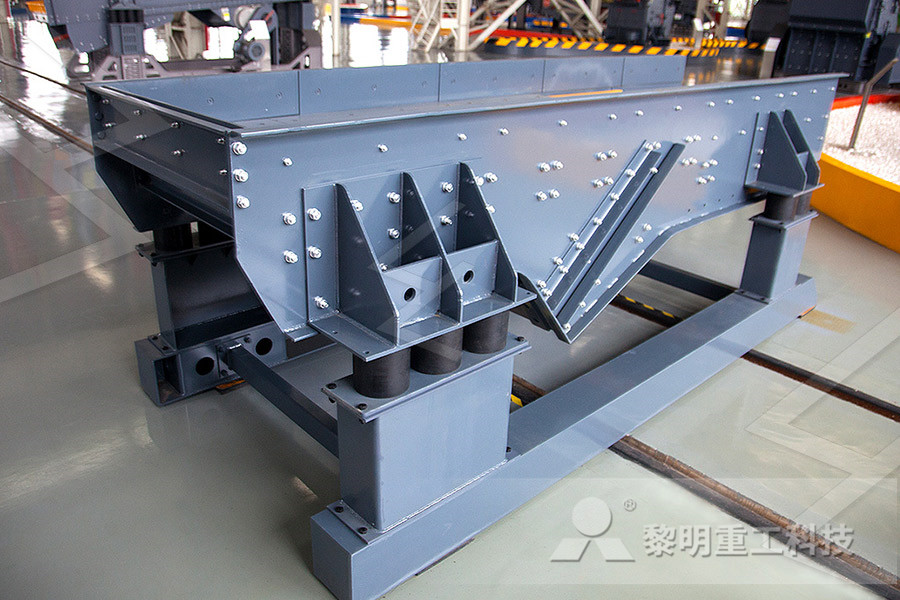

Foamed aerated concrete is a mortar combine by which air voids formed by adding a foaming agent that performs the function of making pores within the concrete without chemically reacting with the cement Detergents, resin soap, gum resins and siphoning are some foaming agentsSand washer Crusher High frequency screen The third create pressureblasting machine Rotary eight holes brick making machine 500 Forced mixer 140Grinding Wheel Type Sand Mixer Classifier Magnetic separator Mixing tank Storage silo Vibrator feeder加气混凝土轻质砖砌块蒸养砖设备河南华意机器 Quick THE EQUIPMENT FOR AERATED CONCRETE PRODUCING The crushed sand is used in aerated concrete producing The gypsum, cement and other additives are added to sand for the strength of the mixture Sand is crushed in the ball mills, the type of grinding is wet ball milling The steel grinding balls 2540 mm in diameter are in the millSand Aerated Concrete Equipment

THE EQUIPMENT FOR AERATED CONCRETE

The crushed sand is used in aerated concrete producing The gypsum, cement and other additives are added to sand for the strength of the mixture Sand is crushed in the ball mills, the type of grinding is wet ball milling The steel grinding balls 2540 mm in diameter are in the mill Each manufacturer has its own milling requirements On average, these requirements tend to the 1518% of Raw material: Cement, Lime, Sand, Gypsum, Aluminum powder, Water From this page, you can get the Lime Kiln,Rotary Kiln,Aerated Concrete Equipment,Autoclave Aerated Concrete Blocks Equipment,Ball Mill,Beneficiation if you are interested in our products,please contact us by Email or telphone, thank youAerated Concrete Equipment/Autoclave Aerated China Aerated Concrete Block Equipment manufacturers Select 2021 high quality Aerated Concrete Block Equipment products in best price from certified Chinese Equipment And System, Machine Equipment Control suppliers, wholesalers and factory on MadeinChinaChina Aerated Concrete Block Equipment, Aerated

Gongyi Fuwei Heavy Machinery Plant aerated

Main products of our company include: aerated concrete equipment, mining machinery, nail making machine, cement production line, brick machine, sandstone equipment, drying machine, bakingfree brick presses, sandmaking equipment, high efficiency and energy saving conical ball mill, rod mill, wet pan mill, magnetic separator, jaw crusher shandong sunshine zotye mechanical engineering co, ltd shandong earliest in the aerated concrete equipment, aerated brick equipment, aerated block device, aerated brick production line of professional manufacturers, the company provides aerated concrete equipment, aerated brick equipment, aerated block equipment, aerated brick production line, aerated concrete equipment manufacturers looking aerated concrete equipmentaerated brick MINGLEI HEAVY INDUSTRY produce Autoclave aerated concrete equipment, Stone Crusher,Roll Crusher,Buringfree brick maker,block machine,brick press machine,Milling Machine,Mining Equipment,Rock Crusher,Grinding Machine,Crushing machine, etc Each series,include maximum,medium and minimum typesAerated Concrete,Autoclave aerated concrete

Changzhou Mingjie Building Material Equipment

AAC Autoclaved Aerated Concrete Block Machine For Tailing Sand Block FOB Price: Negotiable Min Order: 1 Sets; Autoclaved Aerated Concrete Equipment AAC Block Machine For Fly Ash Block FOB Price: Negotiable Min Order: 1 Sets; AAC Spot Welding Machine For Aerated Concrete Panel Reinforced Mesh Assembly FOB Price: Negotiable Min Order: 1 PiecesAutoclave Aerated Concrete Equipment AAC Block Machine For Fly Ash Brick(id:) View product details of Autoclave Aerated Concrete Equipment AAC Block Machine For Fly Ash Brick from Changzhou Mingjie Building Material Equipment Manufacturing Company manufacturer in EC21Autoclave Aerated Concrete Equipment AAC Block Huayi Notice: In order to increase the user experience degrees Huayi aerated concrete equipment manufacturers decided to modify the site, in the revision among Huayi still retain the original data, so that the user to browse, for the revision of Huayi will make better to serve more to aerated concrete set by the user and allows you to easily learned of aerated concrete equipment 加气混凝土轻质砖砌块蒸养砖设备河南华意机器 Quick

THE EQUIPMENT FOR AERATED CONCRETE

The crushed sand is used in aerated concrete producing The gypsum, cement and other additives are added to sand for the strength of the mixture Sand is crushed in the ball mills, the type of grinding is wet ball milling The steel grinding balls 2540 mm in diameter are in the mill Each manufacturer has its own milling requirements On average, these requirements tend to the 1518% of GB0,85 Mixer of aerated concrete is designed for making structural and insulating aerated concrete mixtures of bulk weight 700 – 1000 kg/m 3 It is possible to produce structural and insulating aerated concrete of bulk weight 300 – 400 kg/m 3Equipment for aerated concrete blocks production Sand And Fly Ash Lightweight Concrete Aac Block Brick Making Aac Aerated Concrete Sand Brick Machine Dongyue Group The production line of fly ash aerated concrete block is widely used in our country, because the AAC plant uses sand dust or industrial waste, fly ash and slag gangue as the main raw material, and its frost resistance, corrosion resistance, compressive strength and other concrete sand making equipment aac plant

AUTOMATED PRODUCTION LINE FOR AERATED

The equipment supports both manual and automatic modes 2 Monolith Moulding When ready, the aerated concrete mixture is unloaded to a 085 m 3 mould through the mixer valve The mould is filled at one go It consists of a foundation and detachable interchangeable sidesThe development of aerated concrete equipment in Our country is very rapid and the prospect is very broadAerated concrete has become the pillar industry of China’s construction industryAerated concrete equipment mainly consists of two kinds of production processesVarious technologies such as fly ash aerated concrete block and sand aerated concrete production line equipment have reached Sinopower aerated concrete block equipment The aerated concrete produced by this equipment will be a new type of booming lightweight building material AAC block is made of siliceous materials (sand, fly ash and siliconcontaining tailings, etc) and calcareous materials (lime, cement), blended with a gasgenerating agent (aluminum powder) and goes through compounding、stirring High Performance AAC Block Machine ~ HF Group

aerated concrete equipment, aerated concrete

A Non Autoclaved Aerated Concrete Equipment Aac Block the latest non autoclaved aerated concrete aac production line non autoclaved aerated concrete pany Profile: ShanDong SUNITE Machinery Group Co , Ltd, established in October, 1998 , is a Chinese manufacturer of dedicated in AAC block and panel making machine production line, autoclavingfree foaming concrete block equipment 14 小时前 China Autoclaved Aerated Concrete Equipment Fully Autoclaved Aerated Concrete Equipment AAC Block Plant Fly ash Block Plant Company introduction: Changzhou Mingjie Building Material Equipment Manufacturing Co, Ltd is one special Manufacturer of AAC plant, with more than 15 years' experiences in AAC equipments' production, Most production line have been sent to Iran,India, excellent manufacturer of aerated concrete Autoclave Aerated Concrete (AAC)CHONGQING JEFFER ENGINEERING AND TECHNOLOGY CO, LTDJEFFER Engineering is proficient in design and supply the equipment of autoclave aerated concrete (AAC) plant and engineering serviceAutoclave Aerated Concrete (AAC)CHONGQING JEFFER

Fly Ash Equipment For Fly Ash Aerated Concrete MC

Hollow AAC Sand Lime Slab Plant Lightweight Wall Panel AAC Fly Ash panel machine AAC slab/AAC panel: Aerated concrete plate full name of autoclaved aerated concrete slabs, calcareous and siliceous materials as the main raw material, with aluminum powder for gas material with embalmed the reinforcing mesh sheets, by mixing with water, casting