crushing screening process design sanbaositenl

crushing screening process design Designing a Crushing Screening Plant – Part I Primary ,The jaw crusher is the first stage in the crushing and screening process the main purpose of this stage is to crush the rock into a conveyable size In addition to this other tasks are also performed such as Removal of natural fines soil or other contaminants Production of coarse products such as road base Scientific Method to Design Crushing Screening Plants We should consider how the work is done by crushing machines, hammermills and pure impact crushers lift the kinetic energy of the material to a level where on sudden impingement against a stationary plate breakage occursCrushing Screening Plant Design Factors 911 The crushing and screen process is the crushing procedure composed of crushing machine and screening machine The types of crushing process should be decided according to different crushing sections and different combinations of crusher and screen The basic forms of crushing section are: single crushing operation, a crushing section with What is Crushing and Screening Process? Luoyang

CRUSHING SCREENING Crushing and Screening

The screening process is just as important as the crushing itself Screens are the heart of every rock processing plant They are used to classify materials both in different stages of the crushing process and in final product separation Designed as a nonwelded frame with adjustable vibration features for different material types and screeningThe key point of the process design of the aggregate production plant is to compare the selection of various crushing and screening equipment and the process route, and the comparison of the schemes runs through the whole project design and every detailEssentials of Process Design for Aggregate Crushing Abstract: Crushing and screening processes are often regulated using relaybased on/off controls or, when controlled by PID controllers, the control design is limited to a single crusher and its proximity only The design does not necessarily consider process interactions, load disturbances and, in PID and Predictive PID Control Design for Crushing And

(PDF) Crushing and Screening Handbook Kevin

Crushing and Screening Handbook Kevin Berrocal Download PDF Download Full PDF Package This paper A short summary of this paper 23 Full PDFs related to this paper READ PAPER Crushing and Screening Handbook Download Crushing and Screening There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesCrushing Plant Design and Layout Considerations Productivity and Improved Flowsheet Design K Q'BRYAN Process Machinery Division, Inc, Milwaukee, WI, USA A lOyear program to integrate crushing and screening models into daily flowsheet design practice has proven successful A Circuit Analysis Program (CAP) is used worldwide to design and evaluate new and existing crushingCrushing Flowsheet Simulation: Increased Productivity

crushing screening process design sanbaositenl

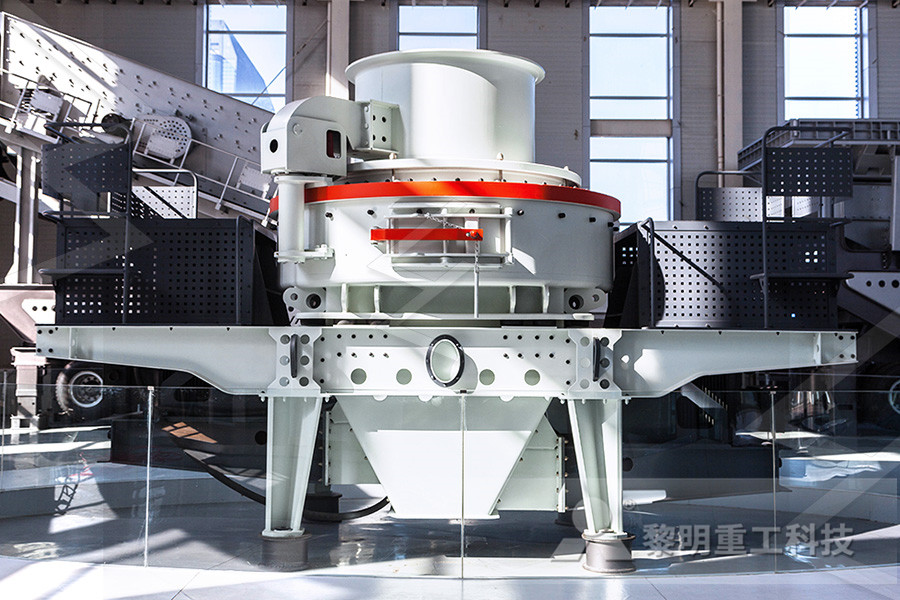

crushing screening process design Designing a Crushing Screening Plant – Part I Primary ,The jaw crusher is the first stage in the crushing and screening process the main purpose of this stage is to crush the rock into a conveyable size In addition to this other tasks are also performed such as Removal of natural fines soil or other contaminants Production of coarse products such as road Luoyang Dahua can design the optimal crushing and screening process according to the customer condition, provide the high quality crusher machine Through several decades development, the company follows the market trend, researches green and environmental protection equipment,provide large benefits for the customerWhat is Crushing and Screening Process? Luoyang DahuaWhen looking at overall crushing circuit design, having the correct number of crushing stages also helps minimize fines production A typical crushing circuit will generate a reduction ration between 5:1 and 7:1 for maximum efficiency For example, to generate a 10mm particle, you’ll want to feed the crusher particles between 50 and 70mmCrushing and Screening for Mineral Processing Success

Factors that impact crushing and screening plant in

Conversely, too little or intermittent feeding, the device will load and reduce production capacity, and a waste of electricity Four, Crushing And Screening Plant process design: Design should be scientific and applicability, the production capacity to support a variety of devices Including the ransport capacity of each of the conveyor belt Crushing and Screening Our aggregate recovery process is designed to cut costs and harmful environmental practices We work to incorporate aggregate recovery into both our foundation design and our enabling worksCrushing and Screening dgscouk contains several crushing and screening phases which should be always considered simultaneously on a control design board Designing PID and Predictive PID controllers for a whole crushing plant does not require models for processes to be controlled However, interactions and nonlinearities of process variables need to be considered and PID and Predictive PID Control Design for Crushing And

Product design of K series crushing and screening portable

The car coating process which we first bring in has advantages as good adhesion, high gloss, high hardness, excellent gloss retention, good resistance to corrosion etc This process well extends the lifespan of the equipment Crushing Flowsheet Simulation: Increased Productivity and Improved Flowsheet Design K Q'BRYAN Process Machinery Division, Inc, Milwaukee, WI, USA A lOyear program to integrate crushing and screening models into daily flowsheet design practice has proven successful A Circuit Analysis ProgramCrushing Flowsheet Simulation: Increased Productivity their projects The crushing screening products within the mineral processing portfolio provide our customers with the a variety of options in developing a bestinclass solution to their process, whether is it for a mine, quarry, or construction site ’s expertise can help to develop the best solution for your projectCrushing Systems

Crushing Plant Design and Layout Considerations JXSC Mine

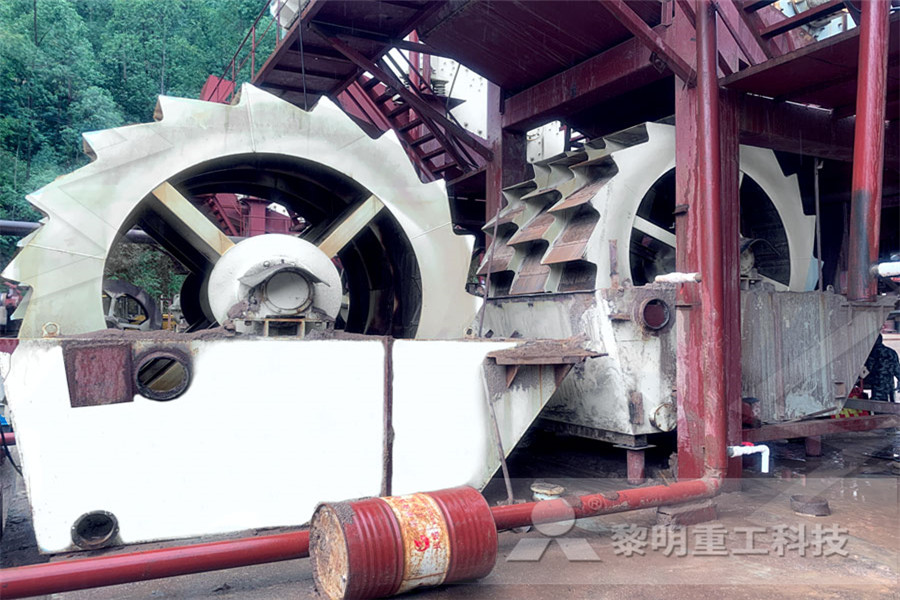

23 Crushing flow with the washing process When the amount of ore containing mud (3 mm) exceeds 510% and the water content is more than 5 ~ 8%, the fine fraction will bond into a mass, which will deteriorate the production conditions of the crushing process, such as blockage of crushing cavity and sieve hole, prone to equipment failures, in Luoyang Dahua can design the optimal crushing and screening process according to the customer condition, provide the high quality crusher machine Through several decades development, the company follows the market trend, researches green and environmental protection equipment,provide large benefits for the customerWhat is Crushing and Screening Process? Luoyang When looking at overall crushing circuit design, having the correct number of crushing stages also helps minimize fines production A typical crushing circuit will generate a reduction ration between 5:1 and 7:1 for maximum efficiency For example, to generate a 10mm particle, you’ll want to feed the crusher particles between 50 and 70mmCrushing and Screening for Mineral Processing Success

Diagram Of Industrial Screening Process

Design and Control of the Cumene Process crushing and screening process flow diagram crushing screening conveying flow chart Equipment used in a coal handling plant Process flow diagram the belt conveyors within the crushing and screening plant, the Coal Chemical Lime, Co: Nelson Lime Plant Permit #42782 Arizona Line from the quarry Crushing and Screening Our aggregate recovery process is designed to cut costs and harmful environmental practices We work to incorporate aggregate recovery into both our foundation design and our enabling worksCrushing and Screening dgscoukCrushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates, introduces different equipment, and demonstrates various processing methodsCrushing and Screening Handbook Outotec

Product design of K series crushing and screening

The car coating process which we first bring in has advantages as good adhesion, high gloss, high hardness, excellent gloss retention, good resistance to corrosion etc This process well extends the lifespan of the equipmentYou can rely on the C Series jaw crusher as the backbone of your process Uncompromised reliability and productivity The reliability of C Series jaw crushers is based on a revolutionary pinned and bolted, nonwelded frame construction This design provides excellent fatigue strength even in toughest quarrying or mining Crushing and screening solutions Automation Crushing Flowsheet Simulation: Increased Productivity and Improved Flowsheet Design K Q'BRYAN Process Machinery Division, Inc, Milwaukee, WI, USA A lOyear program to integrate crushing and screening models into daily flowsheet design practice has proven successful A Circuit Analysis ProgramCrushing Flowsheet Simulation: Increased Productivity

Maden Crushing Screening

MADEN Machinery serves its customers in all fields such as design, manufacturing, quarry installation and erection, aftersales services and spare part supply MADEN Crushing Screening will keep its willingness and enthusiasm for reaching the target their projects The crushing screening products within the mineral processing portfolio provide our customers with the a variety of options in developing a bestinclass solution to their process, whether is it for a mine, quarry, or construction site ’s expertise can help to develop the best solution for your projectCrushing Systems