what is surge bin bondasspecialsnl

using a belt feeder as a surge bin surge bins with feeders crusherasiacom The tests done on the surge bin/belt feeder system can be summarised as follows Measurement of the power consumption of theBelt feeder underneath surge bin TAKRAF delivered the belt feeder as part of a complete crushing and conveying system for Codelco The belt feeder extracts the crushed copper ore from surge bin and feeds it on to overland conveyor Project figures 7,700 t/h: Value for Money We are able to preassemble machines in our workshop and ship in Belt Feeders TAKRAF GmbHDeclining conveyor: a surge bin attached to the tail end of a portable conveyor which utilizes the conveyor belt as a live bottom Read more Belt conveyor 2 Upload, Share, and Discover Content on Live Load In Belt Conveyor At Head For Surge Bin

Conveying TAKRAF GmbH

Belt Feeder underneath Surge Bin in Chile Conveying Belt feeder underneath surge bin Read More Mobile Conveyor Bridge MCB (H) (K) 1400125 in Kazakhstan Conveying Conveyor bridge system resists extreme climate conditions Read More Mobile Transfer Massflow belt feeder interfaceA properly designed belt feeder must also provide increasing capacity in the direction of the feed An effective way to do this is to install a massflow belt feeder interface, as shown in Figure 4 The belt feeder interface should taper in both the plan view and the elevation view to allow material toRetrofitting bins, hoppers, and feeders to solve flow Belt Feeders The slottype belt feeder is one of the most economical feeders for bulk solids Although this type of feeder has been in use for about 50 years, it only has recently found industrial acceptance Properly applied, the belt feeder lends itself Bin Design and Construction 911 Metallurgist

A USER'S EVALUATION OF FEEDER PERFORMANCE

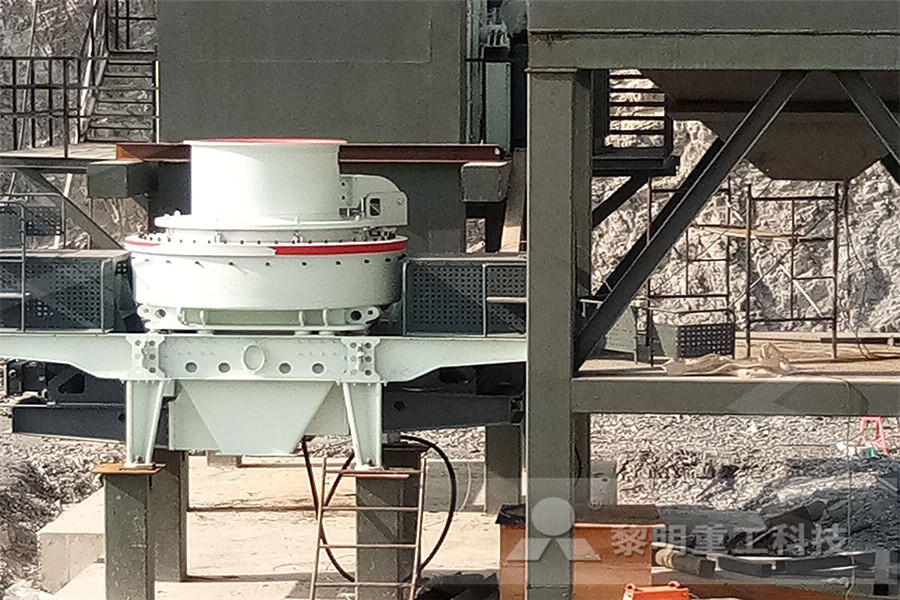

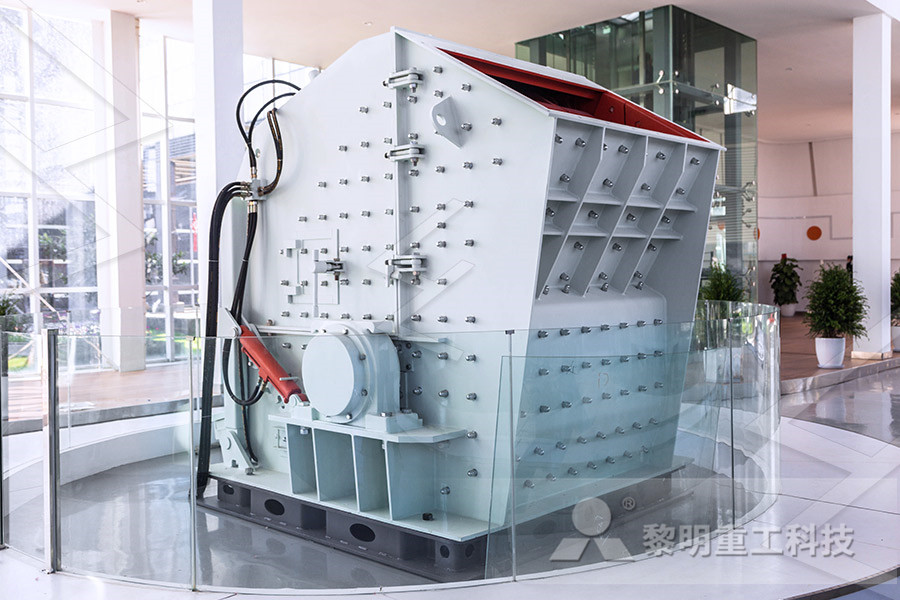

on a 5500 ton mass flow silo/belt feeder installation at Lethabo Power Station The coal flow in the silo and the improvements implemented on the belt feeder are then described A discussion of tests done at Kendal Power Station on a 750 ton capacity surge bin/belt feeder application follow As its name implies, a volumetric feeder modulates and controls the volumetric rate of discharge from a bin (eg, cu ft/hr) The four most common types of such feeders are screw, belt, rotary valve, and vibrating pan A gravimetric feeder, on the other hand, modulates the mass flow rate This can be done either on a continuous basis (the feederHow to Design Efficient and Reliable Feeders for Bulk Solids Surge Bin w/Merrick Model #970 Weigh Belt Feeder, SN 29617 Auction Details Day 1 General Mills Cereal and Snack Food Production Equipment Plant ClosedSurge Bin w/Merrick Model #970 Weigh Belt Feeder,

Belt Feeder Plants of Heavy Duty Steel Construction

It might be a load out bin, or a complete Rip Rap plant, but our belt feeder equipment is efficient, rugged and dependable and proudly American made RD Olson Manufacturing Built for excellence (360) 5777213(360) 5777213 Newsletter Signup fb in Home; Equipment Crushing Plants The feeder acts as both a surge bin to receive and store the load from the shuttle car, and as a feeder to meter the coal onto the belt at a prescribed rate A chain conveyor moves the load from the bin; it may pass the raw coal through a breaker or crusher; and it elevates the material over the belt and drops it onto the conveyor beltImproved Belt Loading Effect on Face Production Surge Bin w/Merrick Model #970 Weigh Belt Feeder, SN 29617 In Day 1 General Mills Cereal and Snack Food PSurge Bin w/Merrick Model #970 Weigh Belt Feeder, SN 29617

Mothae Kimberlite Mine, Lesotho Mining Technology

The DMS surge bin feeds the DMS plant via a belt feeder equipped with a weightometer The DMS tailings are sent to the tailings stockpile while the DMS effluent is recycled to the primary scrubber and screen The DMS concentrate is classified into fractions and batch fed to the recovery plant, followed by drying of the concentrate using a drier 10 The apparatus of claim 9, further comprising a belt feeder with a motor, the belt feeder having a first end disposed below the bottom portion of the surge bin and a second end disposed above an open top portion of the hopper, the belt feeder configured to deliver dry pellet feed from the surge bin into the hopper 11POSTPELLETING LIQUID APPLICATOR SYSTEMS KEMIN This type of feeder may also be used as a picking belt Dimensions and shipping weight are the same as for the Adjustable Stroke Belt Ore Feeder Additional data gladly furnished upon request Hardinge Recording Feeder “Feedometer” The Hardinge Recording Feeder feeds and weighs the material from a bin or surge hopper, and consists of a Types of Small Ore Feeders 911 Metallurgist

Vibrating Feeder Design Stockpile Reclaim General

No return run such as belt feeders eliminates scrapers and spillage They can be designed for dusttight applications Vibrating Feeder Design Types: The mechanism for producing the vibratory forces can be classified as follows: 1 Directforce type in which 100 percent of the vibratory forces are produced by heavy centrifugal counterweights A simplified dynamic model (transfer function matrix) of the virtual silo is given by (20) m 1 q out = 1 s e25 s 1 s e22 s35 s 0 0 35 q in 1 q in 2 u 1, where m 1 is the material mass in the crusher bin and u 1 is the crusher bin reclaim belt feeder control inputMass balance control of crushing circuits ScienceDirect Weigh Belt Feeder Belt Feeders: Belt Feeders are usually considered as a kind of belt conveyor but special designs considered by installation of load cells a weigh belt feeder will be created Plough Scraper Plough Scrapers: Automatically actuated plough scrapers are used to discharge material from belt conveyor to the midwayMechanic and Material Handling Division

How to Calculate Hopper Drag Load, Power, Pressure

In summary, the active weight of material on the feeder belt and, therefore, hopper drag load are linearly proportional to the active volume Our example demonstrated that reducing active volume from 154 ft 3 to 77 ft 3, reduces drag load from 6,769 lbs to 3,384 lbs This, in turn, reduced required conveyor drive power from 232 HP to 122 HPThe surge bin will have a live capacity of 10 minutes for 95 t of storage Surge bin overflow will be transferred to an emergency stockpile via the emergency stockpile conveyor and reclaimed from the stockpile using a frontend loader when required The emergency stockpile will provide 16 hr of storage given a plant feed rate of 57 t/hrMajor Mines Projects Las Chispas Project Massflow belt feeder interfaceA properly designed belt feeder must also provide increasing capacity in the direction of the feed An effective way to do this is to install a massflow belt feeder interface, as shown in Figure 4 The belt feeder interface should taper in both the plan view and the elevation view to allow material toRetrofitting bins, hoppers, and feeders to solve flow

Live Load In Belt Conveyor At Head For Surge Bin

Declining conveyor: a surge bin attached to the tail end of a portable conveyor which utilizes the conveyor belt as a live bottom Read more Belt conveyor 2 Upload, Share, and Discover Content on Surge bin and feeder, possibly belt Crushers 100 ft Inclined chute—poor example A screen directly ahead of a crusher guarantees segregation The chute only serves to aid the problem Screen is often employed where there is a need to remove fines but have a Practical considerations on improved feeding on a 5500 ton mass flow silo/belt feeder installation at Lethabo Power Station The coal flow in the silo and the improvements implemented on the belt feeder are then described A discussion of tests done at Kendal Power Station on a 750 ton capacity surge bin/belt feeder application followA USER'S EVALUATION OF FEEDER PERFORMANCE

Surge Bin Products Suppliers Engineering360

Coal from the reclaim pile is fed by two vibratory feeders, located under the pile, onto a belt conveyor (No 3) that transfers the coal to the coal surge bin located in the crusher tower Development and testing of a high efficiency advanced coal combustor: Phase 3 Industrial boiler retrofit The DMS surge bin feeds the DMS plant via a belt feeder equipped with a weightometer The DMS tailings are sent to the tailings stockpile while the DMS effluent is recycled to the primary scrubber and screen The DMS concentrate is classified into fractions and batch fed to the recovery plant, followed by drying of the concentrate using a drierMothae Kimberlite Mine, Lesotho Mining Technology Handling can improve the technology customers are already using The LinkBelt® expertise and equipment have been instrumental in developing some of the world’s largest belt conveyors The Syntron® feeders are instrumental to supplying Syntron® HeavyDuty Feeders ASGCO

Chute Design Considerations for Feeding and Transfer

chute should be symmetrical in crosssection and located central to the belt in a manner which directs the solids onto the belt in the direction of belt travel • inline component of the solids velocity at the exit end of the chute should be matched, as far as possible, to the belt velocity This is necessary in order to minimise the power 13 Have the contractor run all conveyor belts, except the bin feeder belt 14 Simultaneously start the bin feeder belt and the stop watch 15 When at least 10 tonnes of aggregate have run over the belt scale and before the truck box overflows, simultaneously stop the bin feeder belt and the stop watch 16ATT17/96, PLANT CALIBRATION Part I, Drum Mix Asphalt Portable RAP Bin Weigh Conveyor Inventory Number: 1082RAP/5022465 View DetailsPugmill Mixers, Blending Hoppers, and RAP Bins