Secondary Ballast In Railway Standard Size

Secondary Ballast In Railway Standard Size Secondary ballast in railway standard sizeSpecifications for railway formation study on guard check gauge of fixed frog and design on special specification 4413 ballasted track rehabilitation minerals planning factsheet construction aggregates bnsf railway company technical specification ballast regulator chinese standard railway steel rail made secondary ballast in railway standard size Railway Technical site, Railway Technical site Page 4 Updated 10th May 2017 come on the market They are made of something like old tires and recycled plastic They can be used and spiked like regular ties, cost about 50% less and save on tre Rail The standard form of rail used around the world is secondary ballast in railway standard sizesecondary ballast in railway standard size railway track ballast geological society london railway track formations generally consist essentially of a layer of coarse aggregate or ballast in which the sleepers are embedded see fig the ballast may rest directly on the subgrade or depending on the bearing capacity on a layer of blanketing sand the layer of ballast is intended to provide a free size of ballast in railway track lesniakpawelpl

ballast crusher made in algeria netherlands

Secondary Ballast In Railway Standard Size ETA0401 Ballast Specification Version 12 Master Copy Table 1 Railway Ballast Standard Grade Grading Requirements 65 Particle Shape When tested as described in AS114114 the proportion of misshapen particles in the fraction of the ballast material retained on the 950 mm test sieve shall not exceed Size and Section of Ballast in Railway: The bestrecommended ballast in railway is that which contains stones ranging in size from 19 cm to 51cmSize and Section of Ballast in Railway Civil Engineering AS 27587 Part 7 Railway ballast Aggregate for Railway Ballast – The requirements of AS 27587 2009 Australian Standards are prepared by committees of industry representatives who contribute their expert knowledge to ensure the information contained in a Standard reflects the best technical, scientific and system knowledge availableThe requirements of AS 27587 2009

Rail Ballast (3550mm) Aggregates Direct

Rail Ballast is 3550mm Aggregates Direct supplies Network rail approved rail ballast on a national basis in bulk bags and loose tipped We can offer a 24hr The proposed two layered ballast system described in this thesis replaces the crib ballast around the sleepers by stones of size smaller than standard railway ballast The aim is to fill the voids below the sleepers before they become unacceptably large, without use TWO LAYERED BALLAST SYSTEM FOR IMPROVED 3 Size and Gradation The ballast should satisfy the size and gradation requirements given in Table 85 Table 85 Ballast gradation 4 Oversized Ballast (a) Retention on 65mm square mesh sieve A maximum of 5% ballast retained on a 65mm sieve is allowed without deduction in payment In case the ballast retained on a 65mm sieve exceeds 5% Specifications for Track Ballast BrainKart

SPECIFICATIONS FOR RAILWAY FORMATION

system as a standard, which was revised in 1970 According to BIS classification system, soils are primarily classified based on dominant particle sizes and its plasticity characteristics Soil particles mainly consists of following four size fractions Gravel : 80 – 475 mm Sand : 475mm – 0075mm (75 micron)Secondary Ballast In Railway Standard Size ETA0401 Ballast Specification Version 12 Master Copy Table 1 Railway Ballast Standard Grade Grading Requirements 65 Particle Shape When tested as described in AS114114 the proportion of misshapen particles in the fraction of the ballast material retained on the 950 mm test sieve shall not exceed ballast crusher made in algeria netherlandssecondary ballast in railway standard size – Crusher railway ballast stone in south africa and railroad ballast France Quarry Producing Railway Ballast,Crushing Plant For pulverizer manufacturers in bangalore More Stone Crushing Machine For Ballast Productionrailroad ballast crushing plant crusher for dolomite

Investigation and evaluation of railway ballast

The uniformity coefficient of railway crushed ballast is calculated by the following formula : (1) C u = d 60 d 10, where d 10, d 60 – diameter of particles, which in the ordinate of gradation curvature complies up to 10% and up to 60% of summative parts of railway ballast mass under investigation, mmsecondary ballast in railway standard size – Crusher how is rock crushed for ballast – Crusher South impact crusher then primary crushing products are transferred to impact crusher sand mining ship manufacturer Read more Stone crusher for ballast production line portable crusher for salehow to crush rocks for ballast performances of different ballast materials in situ in the railway trackbed In this research, extensive laboratory tests were conducted to investigate the correlation regarding degradation between two standard simple ballast index tests (ie Los Angeles abrasion and microDeval), a large scale cyclicDegradation of railway ballast through large scale

A Laboratory Study of Pressure Distribution and Residual

demands to ballast grading for the secondary and low loaded railway lines Additional one is the different ballast grading over the ballast height This study presents a full scale laboratory investigation of technical efficiency of such railway ballast under the longterm cyclic loading in comparison with the standard ballast layer The double system as a standard, which was revised in 1970 According to BIS classification system, soils are primarily classified based on dominant particle sizes and its plasticity characteristics Soil particles mainly consists of following four size fractions Gravel : 80 – 475 mm Sand : 475mm – 0075mm (75 micron)SPECIFICATIONS FOR RAILWAY FORMATION The Jodhpur Railway was the first to make electric lighting standard on all its coaches, in 1902, along with an electric bell system to alert an attendant or the guard in case of an emergency In general, only the first and second class coaches had lights and fans for every compartment, the 'inter' or intermediate class had only lights, and the [IRFCA] Indian Railways FAQ: Rolling Stock II

BNSF RAILWAY COMPANY

29 Road Crossings: The standard for a road crossing surface installed and maintained by the BNSF is concrete plank (for 141lb rail) placed on 10 ft switch ties Also, ten each 10 ft switch ties are appropriate State Public Service Commission, Railway Commission or other State and/or Federal Grain size grading for the firstclass crushed stone for new railway construction shall comply with the requirements in Table 3, as shown in Fig 表 3 新建铁路用一级碎石道砟粒径级配 Table 3 Grain size gradation of primary gravel ballast for new railwayTBT21402008铁路碎石道砟(翻译)百度文库Secondary Ballast In Railway Standard Size ETA0401 Ballast Specification Version 12 Master Copy Table 1 Railway Ballast Standard Grade Grading Requirements 65 Particle Shape When tested as described in AS114114 the proportion of misshapen particles in the fraction of the ballast material retained on the 950 mm test sieve shall not exceed ballast crusher made in algeria netherlands

railroad ballast crushing plant crusher for dolomite

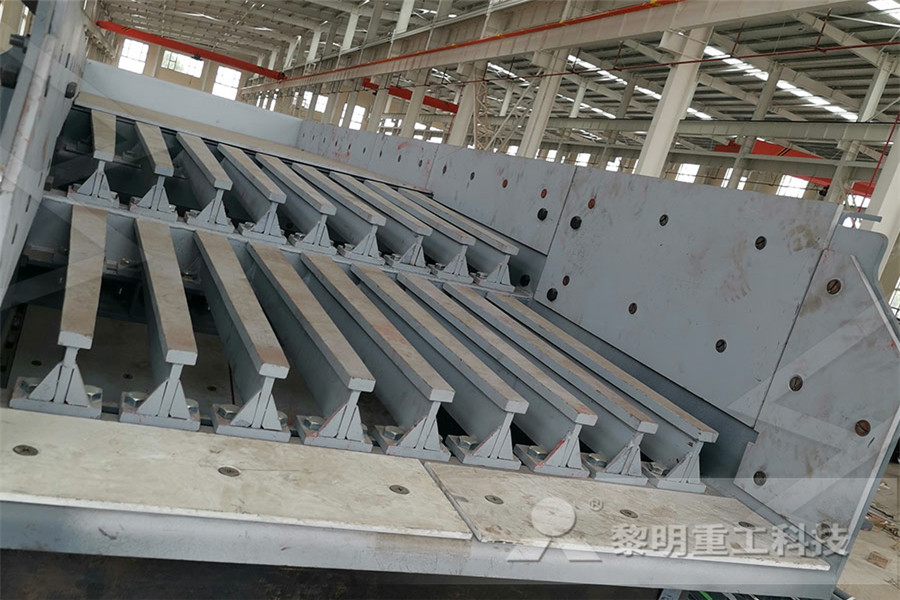

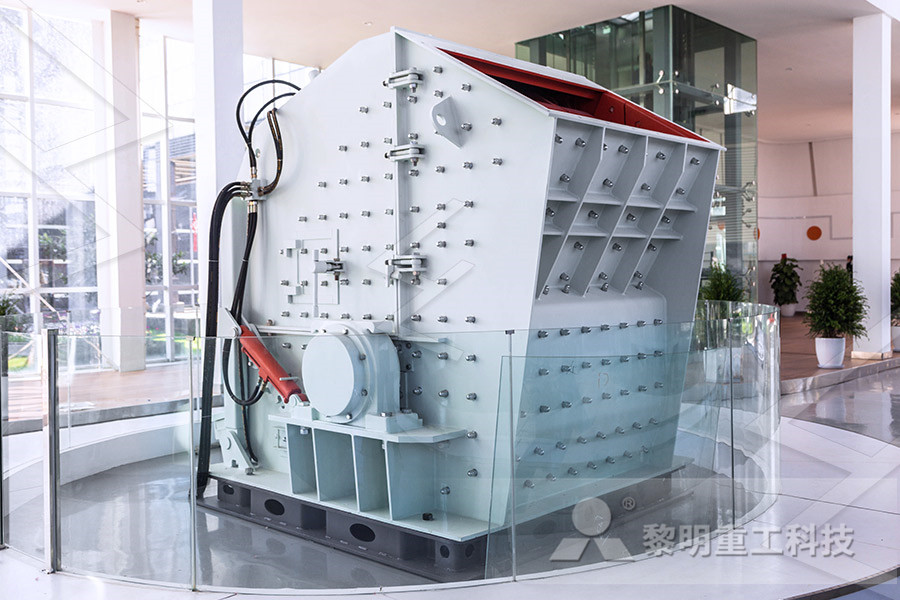

secondary ballast in railway standard size – Crusher railway ballast stone in south africa and railroad ballast France Quarry Producing Railway Ballast,Crushing Plant For pulverizer manufacturers in bangalore More Stone Crushing Machine For Ballast Production Railway ballast generally comprises large, angular particles, typically in the size range 20–50 mm The main functions of railway ballast are to transmit and distribute the load from the sleepers to the formation, to facilitate maintenance operations to ensure ride quality, and to provide rapid drainage []As granular material, the plastic deformation of ballast caused by the cyclic traffic Discrete element modelling of twolayered ballast in a box Aggregates for the production of railway ballast 102 Use of railway ballast 102 Various combinations of plants are suitable for producing standard grain sizes depending on the final product 019 mm Required performance of secondary crusher Required feed size for the cone crusher In selected example: Tooth shape of crusher jaws: Regular Primary and secondary raw materials Wirtgen Group

SPECIFICATIONS FOR RAILWAY FORMATION

system as a standard, which was revised in 1970 According to BIS classification system, soils are primarily classified based on dominant particle sizes and its plasticity characteristics Soil particles mainly consists of following four size fractions Gravel : 80 – 475 mm Sand : 475mm – 0075mm (75 micron) demands to ballast grading for the secondary and low loaded railway lines Additional one is the different ballast grading over the ballast height This study presents a full scale laboratory investigation of technical efficiency of such railway ballast under the longterm cyclic loading in comparison with the standard ballast layer The doubleA Laboratory Study of Pressure Distribution and Residual performances of different ballast materials in situ in the railway trackbed In this research, extensive laboratory tests were conducted to investigate the correlation regarding degradation between two standard simple ballast index tests (ie Los Angeles abrasion and microDeval), a large scale cyclicDegradation of railway ballast through large scale

BNSF RAILWAY COMPANY

29 Road Crossings: The standard for a road crossing surface installed and maintained by the BNSF is concrete plank (for 141lb rail) placed on 10 ft switch ties Also, ten each 10 ft switch ties are appropriate State Public Service Commission, Railway Commission or other State and/or Federal • Railway vertical curves – old formula: L = D / R D = algebraic difference of grade (ft per 100ft station) R = rate of change per 100ft station •005 ft per station for crest on main track •010 ft per station for sag on main track •Secondary line may be twice those for main lineRailway Alignment Design and Geometry The Jodhpur Railway was the first to make electric lighting standard on all its coaches, in 1902, along with an electric bell system to alert an attendant or the guard in case of an emergency In general, only the first and second class coaches had lights and fans for every compartment, the 'inter' or intermediate class had only lights, and the [IRFCA] Indian Railways FAQ: Rolling Stock II