Ball MillDry Process Ball Mill India drmiethde

Dry process ball mill india in nigeria jumbo mining machine dry process ball mill india in nigeria sep 20 2016 the use of ball mills for wet grinding of various materials is a very common and efficient process ball mills are used to grind raw materials ores and minerals like lime or limestone for flue desulphurization coal and several other raw A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, The ball mill can grind various ores and other materials either wet or dry There are two kinds of ball mill, grate type Get Price; Paint Primers Ball Mill, Ball Mill Manufacturers India, Sf Engineering Ball Millsdry process ball mill india makkaronmokotowplBall Mill Manufacturer, Ball mill Supplier, Exporter In Ball mill is an idle tool for grinding many materials into fine powder and it is used to grind different kinds of row materialsThere are two ways of grinding, first is dry process and second is wet processwet and dry ball mills india Products

Ball Mill Manufacturer, Ball mill Supplier, Exporter In

Ball mill is an idle tool for grinding many materials into fine powder and it is used to grind different kinds of row materialsThere are two ways of grinding, first is dry process and second is wet process It are often divided into tubular type and flowing type consistent with various sorts of discharging materialball mill dry process india Wet Grinding VS Dry Ball Mill Grinding Metallurgist Table of ContentsBatch Ball Mill GrindingWet and Dry Open Circuit Ball MillingType of Grind with Different Amounts of Ore Charges in Wet and Dry Ball Milling Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing ball mill dry process india dinapolipizzachartresfrBall Mill For Grinding Lime Mortar Ball Mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes It works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the Ball Mills at Best Price in India

Ball Mill – Promas Engineering Pvt Ltd

Ball mill is an efficient machine for fine powder grinding and key equipment for grinding after the crushing There are two ways of ball mill grinding: the dry way and the wet way It is used to grind many kinds of mineral ores and other materials, or to select the mineDry Grinding VS Wet Grinding Mineral Processing Ball Mill India Manufacturer Supplier Exporter Ball mill is an efficient tool for grinding many materials into fine powder The ball mill is used to grind many kinds of row are two ways of grinding the dry Mill ProcessGrinding Millsdry used ball mill india siostrymistachowiczpl In the production of ethanol, wet ball milling is the process used, because of its versatile process It produces more products than dry ball milling, but in terms of efficiency, capital, and operating cost, most ethanol plants in the USA prefer to use dry ball milling process In other words, dry ball Wet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLC

Ball Mills in Kolkata, West Bengal Ball Mills Price in

Ball Mill (Wet Dry Grinding) The variety of Ball Mill that we design is ideal for performing wet and dry grinding The drive is fabricated using Girth Gear, VBelt that is located on the shell and Pinion The VVFD is offered as per the demands of the customers Clay, Feldspar, Quartz other minerals are perfectly mixed and grind using Ball MillDry Grinding VS Wet Grinding Mineral Processing Ball Mill India Manufacturer Supplier Exporter Ball mill is an efficient tool for grinding many materials into fine powder The ball mill is used to grind many kinds of row are two ways of grinding the dry Mill ProcessGrinding Millsdry used ball mill india siostrymistachowiczpl The steel shots, balls and beads ball mill media are preferred for contamination free and speedy (dry / wet) milling, grinding of solids, liquids dispersion and fine particle size reduction, homogenization of fillers and raw materials, attrition and pulverizing applications in ball, vibro, dyno, pearl, bead, pebble, attritor and smallmedia Grinding Media,Steel Grinding Media,Grinding Media Balls

Process Packaging Line Machineries for Pharmaceuticals

Dry Powder Mixing, Blending, Milling and Grading; Wet Powder Mixing, Drying, Milling, Grading and Blending Fine Powder Manufacturing Process Ball Mill Oil and Paint color/ Dye Homogenizing mixing by colloid mill and stirrer Liquid Particle size reduction by high shear dispo homogenizer and colloid mill Liquid Stirrer Mixing and vessel Turnkey Process System; Dry powder mixing plant; Dry powder mixing plant Coming soon! Quick Inquiry I 39, GIDC, Phase4, Road No A25, Vithal Udyog Nagar 388 121 Dist Anand (Gujarat) India Phone Number +91 2692 Fax Number +91 2692 Email Address info@technodesignsindia Batch Ball Mill; Bead Mill; Pug Mills Techno DesignsRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenization

20TPH Limestone Grinding Plant, Ball Mill

Guidance Limestone/ gypsum dry process/ semi dry process/ wet process desulphurization Hot Products MB5X Pendulous Hanging Grinding Mill represents the The wet process requires 028 tons of coal and 110 kWh to produce one ton of cement, while the dry process requires only 018 tons of coal and 100 kWh of energy In India many types of cement is produced based on different compositions according to specific end applications such as Ordinary Portland Cement (OPC), Pozzolana Portland Cement (PPC Review on vertical roller mill in cement industry its Sunshine Instruments PB No 3910, No 83, Chinny's Chamber, Dr Nanjappa RoadNear Sony Erriscion Service Center Coimbatore , Tamil Nadu, IndiaDry Bath Manufacturer from Coimbatore

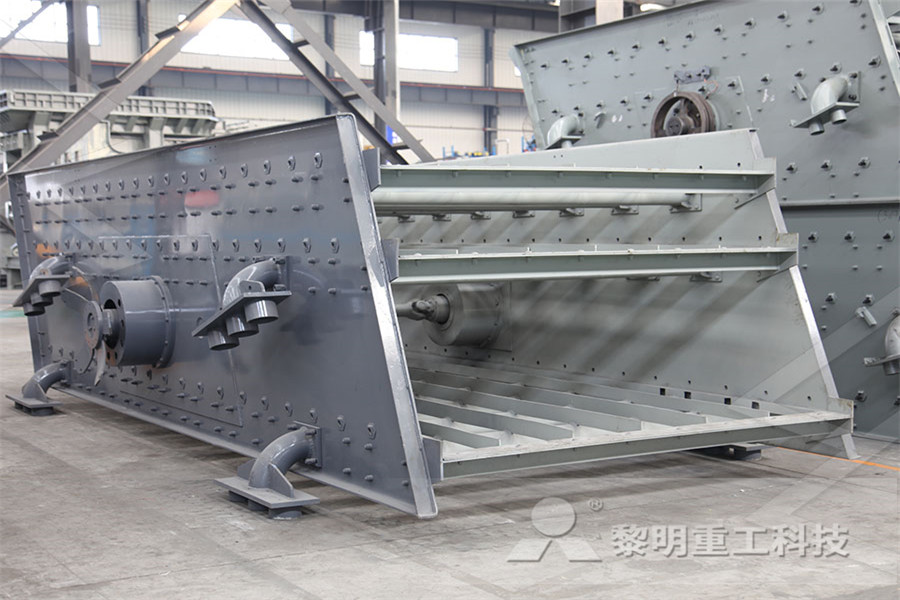

Sell crushing equipment, grinding equipment

Stone Crushing Production Line Stone crushing plant mainly consists of vibrating feeder, jaw Crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control components, and the designed production capacity is 50800t/hball mill dry process india Wet Grinding VS Dry Ball Mill Grinding Metallurgist Table of ContentsBatch Ball Mill GrindingWet and Dry Open Circuit Ball MillingType of Grind with Different Amounts of Ore Charges in Wet and Dry Ball Milling Batch Ball Mill Grinding Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing ball mill dry process india dinapolipizzachartresfrBall mill introduction The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc Ball mill can grind various ores and materials with dry type or wet typeSand Ball Mill, For Industrial, Rs /piece Laxmi

Grinding Media,Steel Grinding Media,Grinding Media

The steel shots, balls and beads ball mill media are preferred for contamination free and speedy (dry / wet) milling, grinding of solids, liquids dispersion and fine particle size reduction, homogenization of fillers and raw materials, attrition and pulverizing applications in ball, vibro, dyno, pearl, bead, pebble, attritor and smallmedia Dry Powder Mixing, Blending, Milling and Grading; Wet Powder Mixing, Drying, Milling, Grading and Blending Fine Powder Manufacturing Process Ball Mill Oil and Paint color/ Dye Homogenizing mixing by colloid mill and stirrer Liquid Particle size reduction by high shear dispo homogenizer and colloid mill Liquid Stirrer Mixing and vesselProcess Packaging Line Machineries for Dry Powder Mixing, Blending, Milling and Grading ; Wet Powder Mixing, Drying, Milling, Grading and Blending Fine Powder Manufacturing Process Ball Mill Oil and Paint color/ Dye Homogenizing mixing by colloid mill and stirrer Liquid Particle size reduction by high shear dispo homogenizer and colloid mill Liquid Stirrer Mixing and vesselApplication : Pharmaceuticals Machines Manufacturer,

cement plant equipments manufacturer and suppliers

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for Fig 1 Ballpowderball collision of powder mixture during reaction milling process 9 Fig 2 SPEX Shaker Mill 14 Fig 3 Planetary Ball Mill 15 Fig 4 Attritor Mill 16 Fig 5 Movement of the ball in the mill with increasing speed of rotation 18 Fig 6 XRD results of Fe powder at different milling hours (when milled in dry conditions) 24DRY AND WET GRINDING BEHAVIOUR OF Fe AND SiO2 Ball Mill is widely applied to dry or wet grinding for ores and grindable materialspany has supplied the ball mill for gold production line in Zimbabwe, phosphate production line in Egypt, silica sand grinding in India, hematite grinding in Iran, etcHow to grind iron ore fines particle– Rock Crusher Mill

Dry and Wet Ball Mill Syntheses of Sb2Se3 from Its

Binary antimony selenide (Sb2Se3) compound was synthesized by the mechanical alloying of constituent elements Both dry and wet mill syntheses methods were applied Dry milling was done in Ar Process: 2 Dry Granulation with Roll Compactor System Powder Row Material Grading sieving Process (Machine – Vibro Sifter) Dry Compaction of the material (Machine – Roll Compactor) Compacted material to be granulated (M/c Oscillating Granulator/Multi Mill) Grading sieving (Machine – Vibro Sifter) Lubrication of granules for free flowing (M/c Blender Octagonal / Double V Pharmaceutical Manufacturing Process : Pharma