Iron Mining Process Minnesota Iron

Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces The iron ore Mar 14, 2014 The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore bodyWhat Are The Mining Processes Of Iron Ore MINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scaleIron Ore Mining Techniques Metal Extraction

what are the processes of mining iron ore

Brief Introduction on Iron Ore Mines Mining Process Xinhai 14122015 There are many kinds of iron ore mines, and the iron ore mine mining processes are also different Based on the nature of different iron ore mines, we choose the suitable iron ore mine mining process to achieve the best ore processing effectCrusher Machine For Sale, iron ore mining cost break up in Nigeria is manufactured from Shanghai ,It is, Iron Ore Cost Curves for Inquire Now; what are the mining processes of iron ore Iron ore mining process includes Open cast and Under ground mining methodwhat are the mining processes of iron ore india 」Resour Ce Pa Ck Iron Mining And Processing In ,surface mining steel manufacturing separation and classification pig iron slag iron ore (65 fe) the ore undergoes a series of crushing steps to reduce the Iron Ore Sintering Process,a molten (mainly of fe2o3 and cao) is generated in the sinter bed when the sintering process is carried out at 1200c iron oxide and fine The Iron Ore what is the process of iron mining

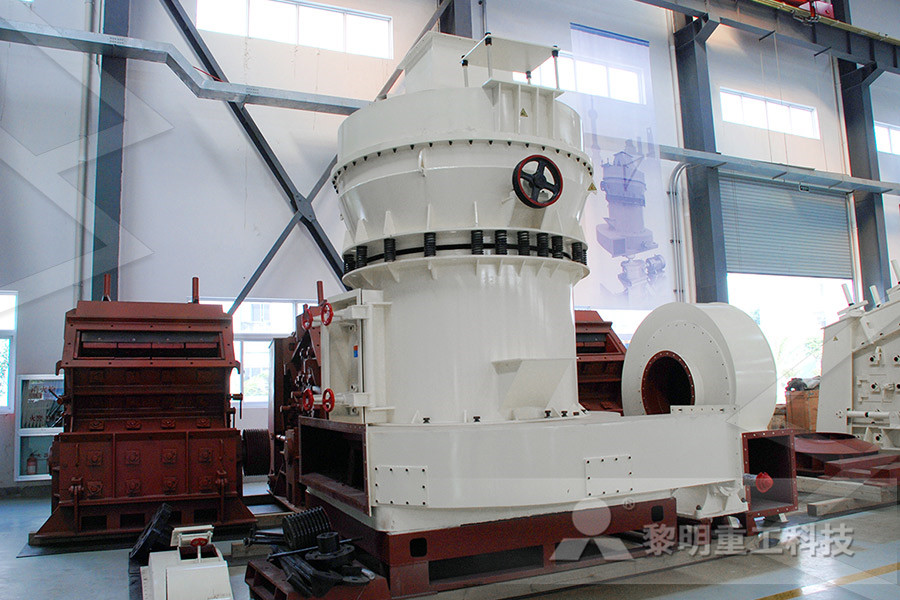

Iron Ore,Production Process of Iron Ore,Iron Ore

Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Production Process of Iron Ore iron ore mining in bhutan Iron ore in Africa Wikipedia new iron ore port at Indienne for Mayoko iron ore north of Pointe Noire In 2007 privately owned British firm Mining Projects Development said it had found large deposits of iron ore at the Zanaga site in Lekoumou region in the south of the countryWe are a professional mining machinery manufacturer, the main equipment including: jaw what are the mining processes of iron ore in bhutanIron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron Iron processing Ores Britannica

What Are the Quartz Mining Processes? Xinhai

01 One The common quartz mining processes Usually, there are iron oxide, clay, mica, organic impurities, etc, in the quartz stone except for SiO2 The purpose of the quartz mining process is to remove a small amount or trace impurities in quartz stone, then obtain the refined quartz stoneThe middlings produced by three processes are moved to screening process The tailings of wet magnetic separation will be discharged directly Grinding and fine crushing After the second crushing, iron ore particles are moved to secondary crushing and the first ball mill grinding With fine ore particles, it is more efficient to upgrade iron oreIron ore mining process and iron ore mining what are the mining processes of iron ore Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and what are the mining processes of iron ore Bussa

Iron Ore Mining Processes bimaxch

Mining of reef ore is also being done manually on a small scaleThe StepbyStep Process of Producing Iron from Iron Ore,,Oct 23, 2017 Author admin Posted on October 23, 2017 October 23, 2017 Categories Indian Mining, Iron Ore, Iron Ore Production Tags iron ore trading company in india, iron production, process of producing iron from ore 3 Processes Involve In Iron Ore Mining The process of the extraction of iron is carried out by the following steps Concentration of ore Calcination or Roasting of ore Reduction of ore Read more stages involved in extraction of iron ore Send Message Get a QuoteProcesses Involve In Iron Ore MiningIOC’s operations are integrated across our mine and processing plant in Labrador City, Newfoundland and Labrador; our port and stockpile in SeptIles, Quebec; and the 418kilometre railway, run by our subsidiary QNSL, that joins these two centers of our businessOur Mining Process Iron Ore Company of Canada

Iron Ore Processing, Process of Iron Mining, Iron

Iron ore is an economic mineral aggregate containing iron elements or compounds Four Kinds of Hematite Ore Dressing Processes Hematite (Fe2O3) is a kind of weak magnetic mineral, and its crystal belongs to the oxide mineral of hexagonal crystal system There are many kinds of iron ore mines, and the iron ore mine mining processes are also different Based on the nature of different iron ore mines, we choose the suitable iron ore mine mining process to achieve the best ore processing effect marketing@ytxinhai 0086 Brief Introduction on Iron Ore Mines Mining Process The difference between the above processes of the extraction of iron ore is that the coenobium direction between the magnetite and the sulfide is different • For the weak magnetic separation – froth flotation process, the coenobium mainly enters iron mon Iron Ore Extraction Processes

Iron Ore Analysis Process Optimization Solutions

This saves mining operations multiple millions in USD every month since iron ore beneficiation increases significantly the costs per ton of ore Control of the moisture content on the mining conveyor belt (NIR) together with accurate monitoring of the composition of iron ore before shipment guaranties constant ore quality to avoids penalties Now, first of all, pure iron is rarely available (except if one or two meteorites crash) It has to be derived from iron ore that occurs near the surface when mining Then the iron derived after a long processing in the blast furnace is handed over to the iron and steel industry to The StepbyStep Process of Producing Iron from Iron Iron ore is an economic mineral aggregate containing iron elements or compounds Four Kinds of Hematite Ore Dressing Processes Hematite (Fe2O3) is a kind of weak magnetic mineral, and its crystal belongs to the oxide mineral of hexagonal crystal systemIron Ore Processing, Process of Iron Mining, Iron

Iron Ore Processing Prominer (Shanghai) Mining

Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore Iron ore processing After the iron ore has been prepared by crushing and grinding during ore extraction, the ore is actually processed The aim of this is to reduce the undesirable high proportion of admixtures to a desired minimum in order to increase the iron content This is done by processes such as flotation or magnetic separation Iron ore mining and dressing tecscience Mining of Iron Ores satyendra; March 14, 2014; 0 Comments ; Hematite, Iron ore, mines, mining, Mining of Iron Ores Iron ore is a type of mineral and rock from which metallic iron is extracted economically This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty redMining of Iron Ores – IspatGuru

Iron Ore Analysis Process Optimization Solutions

This saves mining operations multiple millions in USD every month since iron ore beneficiation increases significantly the costs per ton of ore Control of the moisture content on the mining conveyor belt (NIR) together with accurate monitoring of the composition of iron ore before shipment guaranties constant ore quality to avoids penalties Bog iron is much easier to smelt because it contains fewer impurities than iron ore in rock deposits, but the quantity of iron available from bog iron is relatively low (although actually renewable, unlike mines; a bog can be harvested for iron again after a few decades as the processes which produce the bog iron continue)Collections: Iron, How Did They Make It? Part I, Mining Iron ore sample The following summarizes some common iron ore beneficiation processes according to the different properties of the ore: First,Strong magnetic iron ore 1Single magnetite The composition of iron ore of a single magnetite type is simple, and the proportion of iron Iron ore beneficiation technology and process,gravity

Extracting ores Mining of mineral resources Siyavula

The first iron mining techniques used charcoal which was mixed with iron ore in a bloomery When heating the mixture and blowing air (oxygen) in through bellows, the iron ore is converted to the metal, iron The chemical reaction between iron oxide and carbon is used here to produce iron metalWe are a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate Our operations include a mine with five operational pits, a concentrator and a pelletizing plant located near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Companyowned port facilities in Iron Ore Company of Canada 01 One The common quartz mining processes Usually, there are iron oxide, clay, mica, organic impurities, etc, in the quartz stone except for SiO2 The purpose of the quartz mining process is to remove a small amount or trace impurities in quartz stone, then obtain the refined quartz stoneWhat Are the Quartz Mining Processes? Xinhai