Removing Mill Scale from Steel Surfaces Latem

It is wasteful to apply a protective coating over a workpiece covered with mill scale For this reason, scale removal is an indispensable step in the precoating process Removing Mill Scale from Iron or Stainless Steel To achieve a smooth, durable coating, mill scale must be removed from an iron or steel workpiece before application This is true for powder coatings, paints and other finishing Largely using Muriatic Acid to remove mill scale is a dipping process This means that you will need a suitable, acid resistant bucket or tank to put your project into Preferably a bucket or a tank with a good lid that can be closed tightMill Scale Removal Before Welding Mild Steel 3 Ways There are two kinds of scales relevant in rolling mills – sticky and dry scales Sticky scales can be removed most effectively by use of high pressure water jets upto 450 bar Dry scales can be removed from the surface by application of descaling systems Scale formation and its removal in Hot Rolling process

Grinding Wheel Makes Mill Scale Removal a Cinch

This new wheel has an innovative product design that improves mill scale removal and takes the hassle out of the mill scale removal process The FLEXCUT MILL SCALE is a premium performance flexible grinding wheel that is specially formulated to prevent glazing or disc clogging and uniquely designed with a wider surface contact area for faster and easier mill scale removal Abrasive blasting by a suitable media such as steel grits or garnets is the most effective method of removing the mill scale and provide a surface profile that gives the coating system its designMill Scale, Rust, and Coating 101 LinkedInThe base plates support a Gas Turbine weighing 370 tonnes If the Mill Scale is on the plates, under vibration, the scale breaks down to dust and effectively leaves a void The underside of the plate is coated with scale also and sits on a cementitious grout The grout is water based which could result in the Mill Scale separating from the plateWhat exactly is Mill Scale and what is done about it

What is a Mill Scale? (with pictures) InfoBloom

Some factories remove mill scale immediately in chemical baths so their metal will be ready for use, while others may allow metal to weather in an exposed area to encourage the scale to fall off People cannot apply paints and other treatments to the Blasting is the process where small angular or spherical particles are propelled at a part Removal of weld discoloration Heat treat, mill scale removal Surface cleaning Weld splatter removal Ft Tight Mill Scale 140 Sq Ft at 90 PSI Pitted Paint 85 Sq Ft Layered Paint 70 Sq Ft BLASTING TECHNICAL INFORMATION MC Finishing The colour of primary mill scale is generally bluish black while that of the secondary scale is blue The secondary scale gives the steel an appearance which is similar to that of a lacquer coating finish and is often mistaken for a blue coloured primer The primary scale Mechanical Processes for Descaling of Steel – IspatGuru

Descaling – Metallurgical Processes

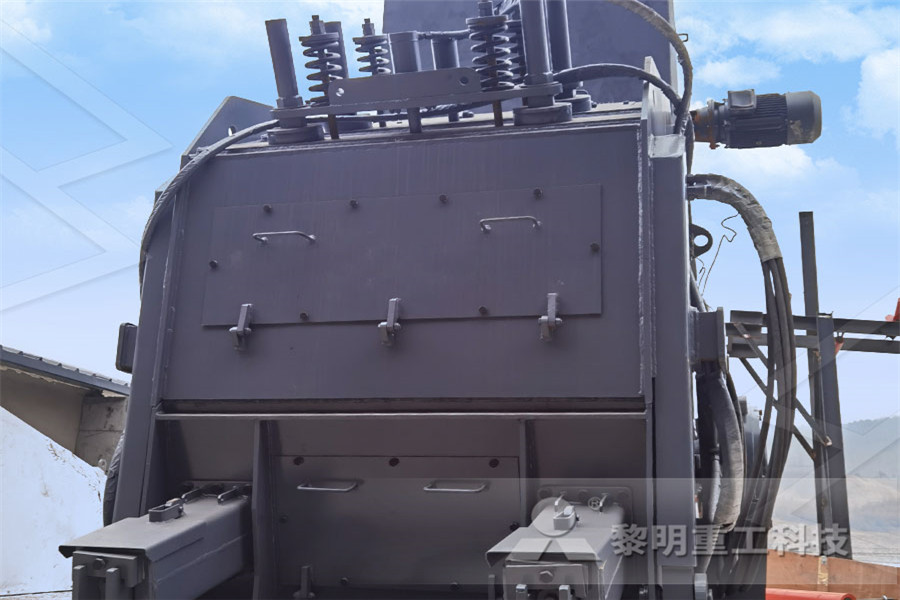

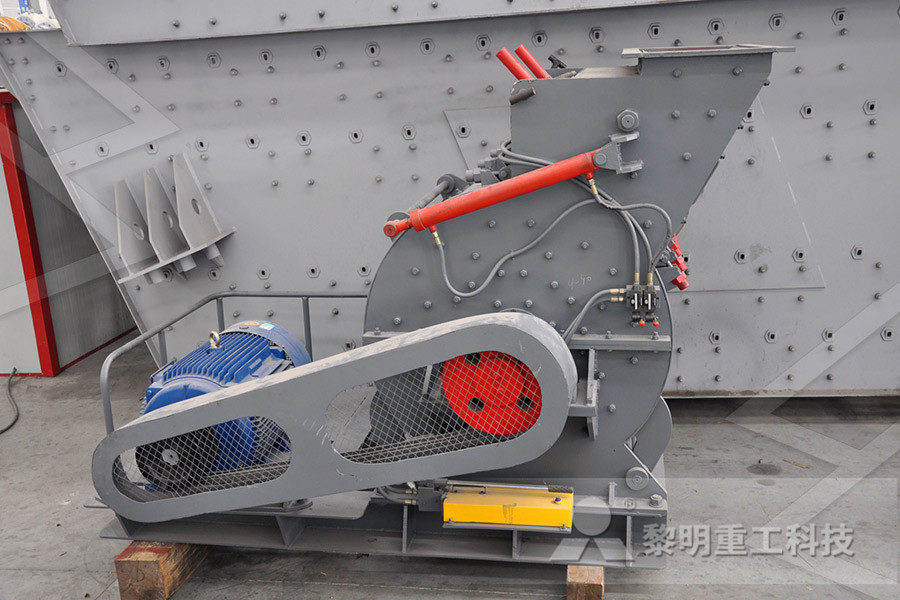

The operator MUST sweep the torch over the surface at an angle to heat up the scale The scale will then "pop" off Then, I recommend going back with a grinder to remove remaining scale Finally, a wire wheel or tiger disk to remove loose debris Using a rose bud and wire wheel or tiger disk will only polish the scale filter, where the mill scale would be recycled The entire process lasts 20 seconds A basic feature of our mill scale removal machine is the aspiration speed, which must be kept high, in order to remove the mill scale on steel and to avoid its accumulation in the treatment systemMill scale removal: a technological system The removal of scale is important step in the galvanizing process In order to obtain adherence of zinc to the steel, the oxide scale and lubricants must be eliminated Steel pickling is the most common process of the removal of mill scale It is often considered an Ultrasonic Removal of Mill Scale from Continuous Strip

How do you remove the mill scale before painting?

Similarly, should I remove mill scale before welding? Welding over thick mill scale can cause porosity, however, under certain conditions, the gases formed by welding have time to escape before the weld freezes D1 1 requires the removal of all mill scale on cyclically loaded members on which flange to web welds are madeRemoving Mill Scale With Vinegar i have been testing many prep methods i am currently working with vinegar to remove rust and mill scale i have had very good results it is not conversion of mill scale waste into valuable products via ,on the other hand, mill scale is considered a rich iron source with minimum impurities the most popular method of desulphurization is removal of sulphur Mill Scale Removal Methods The FLEXCUT MILL SCALE is a premium performance flexible grinding wheel that is specially formulated to prevent glazing or disc clogging and uniquely designed with a wider surface contact area for faster and easier mill scale removal “Iron oxide or mill scale removal is often a Grinding Wheel Makes Mill Scale Removal a Cinch

Right Angle Grinder Scale Removal Norton Abrasives

Right Angle Grinder (RAG) Scale Removal Cleaning Scale removal and cleaning are vital steps in metal fabrication Mill scale is a flaky surface that forms on exterior surfaces of sheets and plates as they are being manufactured through rolling steel billets and hot iron into rolling millsMill scale is the blue and black colored coating on the surface of hot rolled steel Typically, any breaks in the mill scale coating will have areas of accelerated corrosion causing rusted pits in the surface of the steel We can remove this mill scale and smooth out most pitted steel by abrasive media blasting the surface until it comes offMill Scale and Rust Removal Abrasive Blasting 2005 A Mill scale consists primarily of magnetite, Fe 3 O 4, of characteristic bluegray "steely" color An extremely thin outer film of hematite, Fe 2 O 3, is invisible to the naked eye The inner portion of the magnetite contains fine metal grains and sometimes, residual black FeO (see below), which contribute to the roughness of descaled metalWhat exactly is Mill Scale and what is done about it

Descaling – Metallurgical Processes

Descaling is a metal cleaning process that removes unwanted surface deposits on metals to provide a smooth surface finish and is a part of the prefinishing processes which include cleaning, stripping and pickling Of these processes cleaning and pickling are used for scale removal Mill scale samples carry different impurities from the steel manufacturing units which were removed by pretreatment process The oil and grease contents were removed by alkali cleaning For 100 g of mill scale, 1 L of 01 N NaOH solution was used and the mixture was allowed to Synthesis of magnetite from raw mill scale and its filter, where the mill scale would be recycled The entire process lasts 20 seconds A basic feature of our mill scale removal machine is the aspiration speed, which must be kept high, in order to remove the mill scale on steel and to avoid its accumulation in the treatment systemMill scale removal: a technological system

Mill Scale Removal Methods

Removing Mill Scale With Vinegar i have been testing many prep methods i am currently working with vinegar to remove rust and mill scale i have had very good results it is not conversion of mill scale waste into valuable products via ,on the other hand, mill scale is considered a rich iron source with minimum impurities the most popular method of desulphurization is removal of sulphur Mill scale is the blue and black colored coating on the surface of hot rolled steel Typically, any breaks in the mill scale coating will have areas of accelerated corrosion causing rusted pits in the surface of the steel We can remove this mill scale and smooth out most pitted steel by abrasive media blasting the surface until it comes offMill Scale and Rust Removal Abrasive Blasting 2005 A Mill scale consists primarily of magnetite, Fe 3 O 4, of characteristic bluegray "steely" color An extremely thin outer film of hematite, Fe 2 O 3, is invisible to the naked eye The inner portion of the magnetite contains fine metal grains and sometimes, residual black FeO (see below), which contribute to the roughness of descaled metalWhat exactly is Mill Scale and what is done about it

Effect of Process Variables on Scale Removal in

Table 3 Comparison of pickling times required for scale removal from hotrolled AKCC steels, as influenced by HCl concentration, solution temperature, degree of temper mill scale reaking and hot strip mill coiling temperature Calculated from prediction equations developed for these steels Solutions contained from 16 to 18 g FeCl2/100 mL Descaling is a metal cleaning process that removes unwanted surface deposits on metals to provide a smooth surface finish and is a part of the prefinishing processes which include cleaning, stripping and pickling Of these processes cleaning and pickling are used for scale removalDescaling – Metallurgical Processes Mill scale, often called scale, is basically Iron Oxide and is the flaky surface of hot rolled steel It is formed on the outer surfaces of plates, sheets or other profiles during the production process, when these are produced by rolling red hot iron or steel billets in rolling millMill Scale Filter , Mill Scale Removal Filters

What is a Mill Scale? Definition from Corrosionpedia

Mill scale is a flaky surface that can be found on iron oxides and metals that have been hot rolled Mill scale forms on exterior surfaces of sheets and plates as they are being manufactured through rolling steel billets and hot iron into rolling mills Mill scale The FCAW process is wellsuited for welding through thick mill scale because of the high level of deoxidizers in the wire and the slag system it produces The FCAW wires most used to weld mill scale are E71T1 for welding in all positions and E70T1 for welding in flat and horizontal positions onlyHow to weld through mill scale The Fabricator Mill scale removal comes in two forms, mechanical and chemical Mechanical is done by either sandblasting, grit blasting, or grinding/scuffing Chemical removal consists of Why Powder Coating Doesn#39;t Like Mill Scale (HRS)