Ball Mill Discharge Spiral and Trommel Screen

The Ball Mill Discharge Spiral Screen is designed to make a sized product, particularly for “SubA” Unit Flotation Cells and concentrating tables It is also used to screen out and return to the ball mill any oversize in a ball millclassifier circuit when ball mill discharge sizing maintenance Gulin Solutions mel screen discharge area of the mill to remove tramp metal and ball fragments from the dis Grate Discharge Ball Mill 1ISO9001:2000,CE; 2Input size:1525mm; Ball Mill Discharge Screen Crusher Mills, Cone A wide variety of ball mill discharge options are available to you, such as family homes, raw water intake, and metal and equipment manufacturers You can also choose from ce, csa, and rohs ball mill discharge, as well as from 1 year, more than 5 years ball mill discharge, and whether ball mill discharge is circularball mill discharge, ball mill discharge Suppliers and

Grate Discharge For Ball Mill Crusher Mills, Cone

Screen Discharge Ball Mill For Sale,Conical Ball Mills For Grate Discharge Ball Mill Used in wet and dry grinding in both open and closed circuits, a grate discharge ball mill (sometimes known as JXSC start the ball mill business since 1985, supply globally service includes design, manufacturing, installation, and free operation training 【Type】 according to the discharge type, overflow ball mill, grate discharge ball mill; according to the grinding conditions, wet milling, dry grinding; according to the ball mill Ball Mills Industry Grinder for Mineral Processing Trommel screens are often included as a classification stage at the discharge end of AG, SAG and ball mills to ensure correct sizing of product from the mill and to separate out oversize material and ball scats from the undersize product/slurry stream that passes through the screen apertures for further processing bined DEM and SPH simulation of overflow ball

SAG MILL DISCHARGE SCREENSTROMMEL vs

mill has a trommel on the discharge end of it Oversize is returned to the mill by a bucket wheel and water jet Trommel undersize was pumped to a vibrating screen where the screen oversize was sent back to the mill and the undersize was pumped to the cyclone circuit Figure 2 shows the flowsheet for line 2 with only the trommel, Converting a ball mill from overflow to grate discharge involves installing a grate inside the mill at the discharge end The grate holds the balls inside the mill but allows the slurry to pass through, and it is then pumped out of the mill by the pulp lifters This is different to an overflow mill which holds the slurry and balls inside until Converting a ball mill from overflow to grate Ball Mill Discharge Figures 11 and 12 indicate how a trommel screen is replaced by a trunnion magnet system The trunnion magnet is mounted at the ball mill discharge pointMagnetic Separation Techniques to Improve Grinding

Ball Mill British Rema

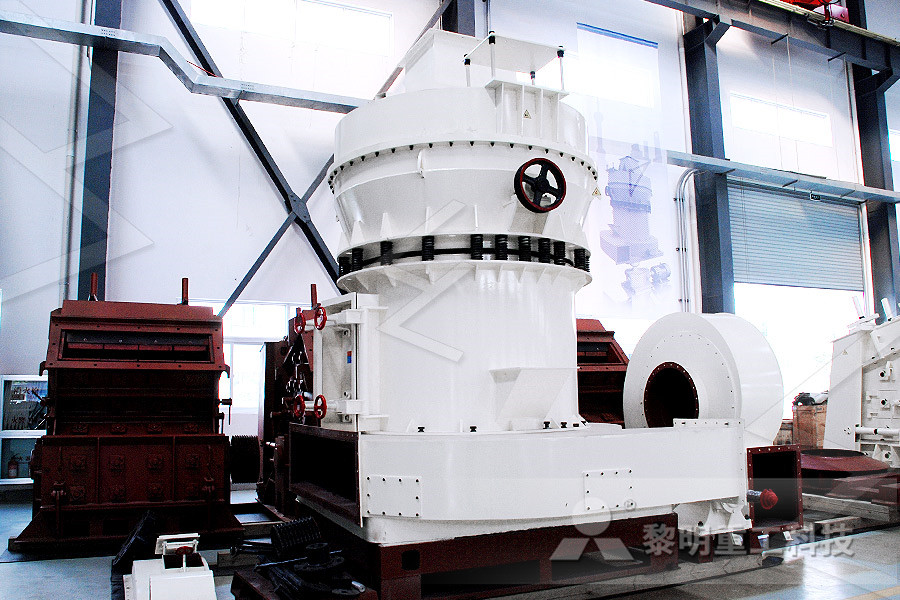

Screen Discharge Mill The Screen Discharge Mill is designed for continuous operation and produces a relatively coarse product with minimum generation of superfines The grinding chamber is formed from a set of replaceable cast steel perforated grinding plates bolted to shaftmounted endplates fitted with renewable segmented steel linersThe mill also includes the processes of attrition and impact although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforations The mill consists of a rotating shaft with four attached parallel knives and a screen grate discharge for ball mill abetclScreen Discharge Ball Mill For Sale,Conical Ball Mills For Grate Discharge Ball Mill Used in wet and dry grinding in both open and closed circuits, a grate discharge ball mill (sometimes known as Grate Discharge For Ball Mill Crusher Mills, Cone

ball mill discharge types

ball mill discharge, continuous ball mill systems screen discharge mills grate type ball mill belongs to low level forced discharge type Grinding equipment mill cylinder body store little pulp, finely ground particles can be discharged in new discharge grid design for ball mills: technics amp; technolgy of discharge screen Screen undersize flowed into the mill discharge hopper before being pumped for classification in Krebs 250 mm (10inch) cyclones Cyclone underflow flowed to the secondary ball mill feed, with a portion processed in a gravity circuit before being recombined to form the ball mill Taking Control of the Mill Feed R2 OrwayBall mills 911 metallurgist the peripheral discharge type of ball rod mill is aType, and is recommended where a free gravity discharge is Gravity discharge ball mills Gravity wet ball mill ball millThe wet ball mill has two types as follow grid type and overflow type the grain size limit of the grinding mill Get Pricegravity discharge ball mills Prominer (Shanghai)

Air swept ball mill ALLIS CHALMERS MFG CO

In an air swept ball mill having a grinding Sspace and a hollow discharge trunnion, a constant discharge chamber comprising an annular foramious grid spaced from the discharge end of said mill, a frustoconical screen in said chamber having its base secured in the central opening of said annular grid and its smaller end connected to a Overview Ball mill is the key equipment for deep grinding of materials after primary crushing It is widely used in cement, silicate products, new building materials, wearresistant materials, fertilizers, ferrous and nonferrous metal mineral processing and glass ceramics industriesBall millVanguard Machinery there has been a shift of emphasis on ball mill optimization to semiautogenous grinding (SAG) mills In order to optimize this section, the skills to accurately model and understand its underlying mechanisms are required AG / SAG Milling, SAG mill, Discharge, Comminution, Aperture, Pebble port, Grate, ClassificationImproved Relationships for Discharge in SAG/AG Mills

Updated magnetic separation techniques to improve

These improvements were necessary to magnetically collect grinding ball fragments directly from the mill discharge stream without the use or requirement of a trommel screen The magnet barrel (or blind trommel) is bolted directly to the discharge flange of the mill and is coupled with an arc of permanent magnets to collect grinding media Screen Discharge Mill The Screen Discharge Mill is designed for continuous operation and produces a relatively coarse product with minimum generation of superfines The grinding chamber is formed from a set of replaceable cast steel perforated grinding plates bolted to shaftmounted endplates fitted with renewable segmented steel linersBall Mill British Rema The model includes the last 15 m axial length of the end section of a 6 m diameter overflow ball mill with a trommel screen attached for collecting the mill discharge as shown in Fig 3 This geometry was built from details estimated from a range of manufacturer website sources and is not intended to correspond to any specific mill/trommel Combined DEM and SPH simulation of overflow ball

Taking Control of the Mill Feed R2 Orway

discharge screen Screen undersize flowed into the mill discharge hopper before being pumped for classification in Krebs 250 mm (10inch) cyclones Cyclone underflow flowed to the secondary ball mill feed, with a portion processed in a gravity circuit before being recombined to form the ball mill Overview Ball mill is the key equipment for deep grinding of materials after primary crushing It is widely used in cement, silicate products, new building materials, wearresistant materials, fertilizers, ferrous and nonferrous metal mineral processing and glass ceramics industriesBall millVanguard MachineryBall mills 911 metallurgist the peripheral discharge type of ball rod mill is aType, and is recommended where a free gravity discharge is Gravity discharge ball mills Gravity wet ball mill ball millThe wet ball mill has two types as follow grid type and overflow type the grain size limit of the grinding mill Get Pricegravity discharge ball mills Prominer (Shanghai)

Improved Relationships for Discharge in SAG/AG Mills

there has been a shift of emphasis on ball mill optimization to semiautogenous grinding (SAG) mills In order to optimize this section, the skills to accurately model and understand its underlying mechanisms are required AG / SAG Milling, SAG mill, Discharge, Comminution, Aperture, Pebble port, Grate, ClassificationBall mill, also known as ball grinding machine, a wellknown ore grinding machine, widely used in the mining, construction, aggregate applicationJXSC start the ball mill business since 1985, supply globally service includes design, manufacturing, installation, and free operation trainingBall Mills Industry Grinder for Mineral Processing These improvements were necessary to magnetically collect grinding ball fragments directly from the mill discharge stream without the use or requirement of a trommel screen The magnet barrel (or blind trommel) is bolted directly to the discharge flange of the mill and is coupled with an arc of permanent magnets to collect grinding mediaUpdated magnetic separation techniques to improve

What are the differences between ball mill and rod

Though there is no sieve plate, the discharge pipe is cast with reverse threads, which makes that the large ores and balls are hard to discharge from the ball mill machine Overflow discharge ball mill can grind ores into the size under 02 mm, so it is very suitable for the second grinding system 3D Rotary vibrating screen introduction: 3D Rotary Vibrating Screen is a highprecision powder griddle, low noise, high efficiency, quick changer takes 35 minutes, totally enclosed structure, for grain, flour, mucus and other materials screening filter 3D r otary v ibrating s creen is a motor for vertical excitation source, the motor and lower eccentric weight installed at both ends of the 3D Rotary Vibrating Screen Lab ball mills,Lab Powder