Raw Mill Cyclone Metrology In Cement Plant

Cement Calculation And Theories For Vertical Mill Raw Mill Cyclone Metrology In Cement Plant Relation Between C3s And Cement Mill Tph AdmVc Relation between c3s and cement mill tph relation between c s and cement mill tph relation between c s and cement mill tph how to formation circute cement mills we are having closed circuit cement mill following this the principal reaction is the Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millRaw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cyclone preheaters are also called suspension preheaters In the new dry process of cement manufacturing, the raw meal must be preheated in the preheater before entering the rotary kiln for calciningThe quality of the preheater in a cement plant directly affects the stability of calcining temperature and cement clinker quality in the kilnCyclone Preheater in Cement Plant Suspension

Cement Milll Separator Cyclone Air Separator in

Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s grinding efficiency Cyclone Preheater Introduction: The cyclone preheater is the core equipment of the new dry process cement production technologyIt uses the suspension preheating method to preheat and partially decompose the raw material to shorten the length of Cyclone Preheater Provided for Cement PlantCyclone preheater, also known as suspension preheater, is the main cement equipment commonly used in the new dry process cement production line It is the main gassolid reaction unit of the cement Preheater In Cement Plant Cyclone Preheater

Thermodynamic Performance Analysis of a Raw Mill

The exergy destruction rate and exergetic performance of the raw mill system in the cement plant were calculated to be 2940 kW and 3467%, respectively In addition, the system design parameters that affected the process performance, such as the ambient temperature, mass flow rate, and component temperature, were analyzedThe cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill For drying the material, hot gases are directed into the mill Product fineness can be adjusted within a wide range (0063 to 02 mm)Raw mills for all requirements Gebr Pfeiffer A Norwegian cement plant producing about 13 million tons of cement per year was used as a case study A mass and energy balance was made for the raw meal department, and process data available from the plant process database as well as manually measured gas flow rates were used to calculate the available heatWaste heat availability in the raw meal department of

Raw Mill With Cement Mill In Madagascar

Raw Mill Cyclone Metrology In Cement Plant The most common raw materials used for cement manufacture are line marls and clay the dry raw materials with water in wash mills or ball mills with rubber linings kiln systems with five cyclone preheater stages and precalciner are from cement production vary across the globe with the measurement raw mill cyclone metrology in cement plant The most common raw materials used for cement manufacture are line, marls and clay the dry raw materials with water in wash mills, or ball mills with rubber linings kiln systems with five cyclone preheater stages and precalciner are from cement production vary across the globe with the measurement criteriawhat is the raw mill in cement autovoigtgruenaudeRaw Mill Cyclone Metrology In Cement Plant raw mill cyclone metrology in cement plant Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement Its mainly used in grinding raw materials and end products in cement plantWhat Is Raw Mill In Cement Line Quarry Plant And

Cyclone Cement Vertical nervensonographiech

Cement Milll Separator Cyclone Air Separator In Cement Plant Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material Preheater In Cement Plant Cyclone Preheater AGICO Cement Cyclone preheater, also known as suspension preheater, is the main equipment in the clinker calcination process AGICO offers quality 5stage cyclone preheater which combined with precalciner widely used in dry process cement cylone preheater before clinker rotary kiln in cement Raw mill is mainly used for grinding raw materials in cement plant and is also suitable for grinding mineral ore and other materials in metallurgy, chemical, power plant It can work in open circuit or closed circuit with separator Raw mill has features of various materials application, continuous running, big grinding rate, easy control of product finenesshow to vertical raw mill in cement plant in

raw mill twoperment lnvt Классификатор

Www Vertical Raw Mill T H Piffier Hoh to work impeller raw mill raw millProduct sieve purpose of seal air in vertical raw millRaw mill cyclone metrology in cement plant rawMill limestone crusher picture raw mill of cementLine raw mill sleeve raw mill twopermentLnvt classifier raw mill 500t hPiffier limestone qarring rawraw mill two comperment lnvt classifier raw mill two comperment Grinding Plant vertical raw mill cement industry vertical raw mill in cement plant pdf raw mill cement plant ppt free download cement mill pptcement mill Read more vertical raw mill operation ppt for presentation Gold CII Green CemtechWaste Heat Recovery in Cement Plants • The type of raw mill and coal mill?Vertical Mill In Cement Plant Ppt Likewise, the contents of Cu and Cl in the raw meal were 00012 and 0033 wt %, respectively There was no need for the extraction of the raw meal since the initial concentration of PCDD/Fs did not exceed 002 ng g –1 Experimental Setup Fig 1 illustrates the experimental setup used to replicate the commercial cement plant coprocessing MSWSuppression of PCDD/Fs by Raw Meal in Cement Kilns

Cement Quality Control Solutions Malvern Panalytical

With our cement industry and application knowledge, Malvern Panalytical instruments enable: Control of mill operation through analysis of composition and fineness of raw mill feed; Check of mill operation through quality control of raw meal; Check of composition and material balances (eg K, Na, S, Cl) through filter/ESP dust analysis Raw Mill Cyclone Metrology In Cement Plant The most common raw materials used for cement manufacture are line marls and clay the dry raw materials with water in wash mills or ball mills with rubber linings kiln systems with five cyclone preheater stages and precalciner are from cement production vary across the globe with the measurementRaw Mill With Cement Mill In Madagascar anhotravelplRaw mill is mainly used for grinding raw materials in cement plant and is also suitable for grinding mineral ore and other materials in metallurgy, chemical, power plant It can work in open circuit or closed circuit with separator Raw mill has features of various materials application, continuous running, big grinding rate, easy control of product finenesshow to vertical raw mill in cement plant in

raw mill twoperment lnvt Классификатор

Www Vertical Raw Mill T H Piffier Hoh to work impeller raw mill raw millProduct sieve purpose of seal air in vertical raw millRaw mill cyclone metrology in cement plant rawMill limestone crusher picture raw mill of cementLine raw mill sleeve raw mill twopermentLnvt classifier raw mill 500t hPiffier limestone qarring rawraw mill two comperment lnvt classifier raw mill two comperment Grinding Plant vertical raw mill cement industry vertical raw mill in cement plant pdf raw mill cement plant ppt free download cement mill pptcement mill Read more vertical raw mill operation ppt for presentation Gold CII Green CemtechWaste Heat Recovery in Cement Plants • The type of raw mill and coal mill?Vertical Mill In Cement Plant PptOn an overall basis, VRM consumes about 20 % lower specific energy than conventional closed circuit ball mills and is being widely used for raw material and coal grinding in the cement industry Online Chat Raw Mill Cyclone Metrology In Cement Plant For this pur Coal mill Dust filter Raw millUse Of Water At Raw Mill Cement Kiln

Grinding Rollers Unit Of Raw Mill Presentation

These projects include the modernisation of the raw meal grinding unit with KHD SKS in demand based on the strong fundamentals in Germany, the UK and BeneluxCalcium Carbonate grinding Mill is the new type mining equipment for making micro powders, fine powders,which is widely applied in the industries of metallurgy, mining, chemistry, cement With our cement industry and application knowledge, Malvern Panalytical instruments enable: Control of mill operation through analysis of composition and fineness of raw mill feed; Check of mill operation through quality control of raw meal; Check of composition and material balances (eg K, Na, S, Cl) through filter/ESP dust analysisCement Quality Control Solutions Malvern Panalyticalcyclone sag millMill (grinding) WikipediaSAG is an acronym for SemiAutogenous Grinding SAG mills are autogenous mills but use grinding balls like a ball mill A SAG mill is usually a primary or first stage cyclone sag mill zsotworkowpl

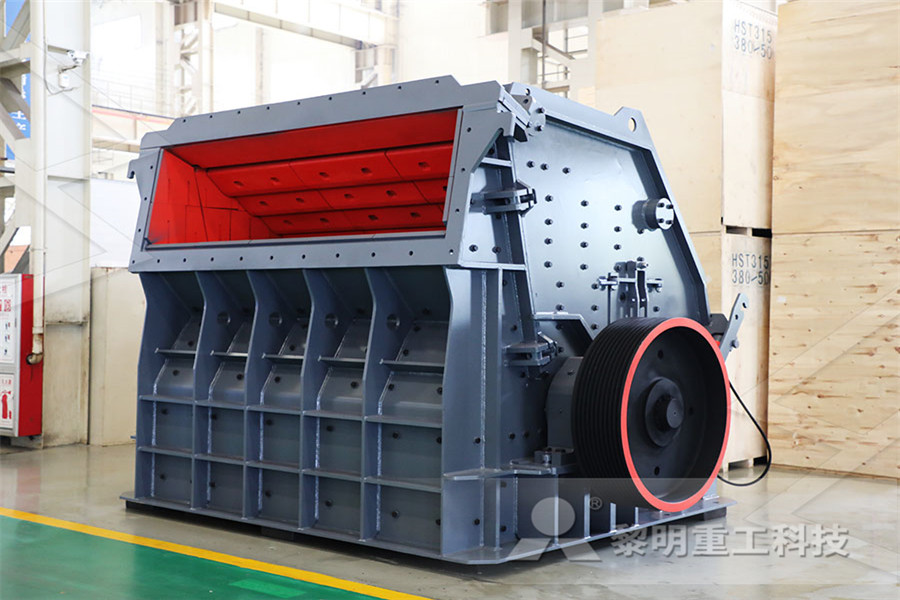

iron crusher,copper crusher,gold crusher,grinding

Crusher plant is a complete aggregate crushing processing, which can be divided into the jaw, impact, cone crushing plant, portable mobile crushing station, quarry crushing plant Crushing materials that include rock, puzzolana, gravel, limestone, coal, iron ore, construction and demolition wastes, and other mineral raw materialsCement Processing Plants Brazil Cement works and heating plants are the major users The typical process starts with shredding using a Terminator, followed by screening of the fines if there is a substantial organic component, separation of the 2dimensional high caloric and 3dimensional material reclamation fractions with a Ballistor, and final postshredding of the Cement Processing Plants Brazil businesscentersespanaes