Aggregate SMICO Vibratory Screens

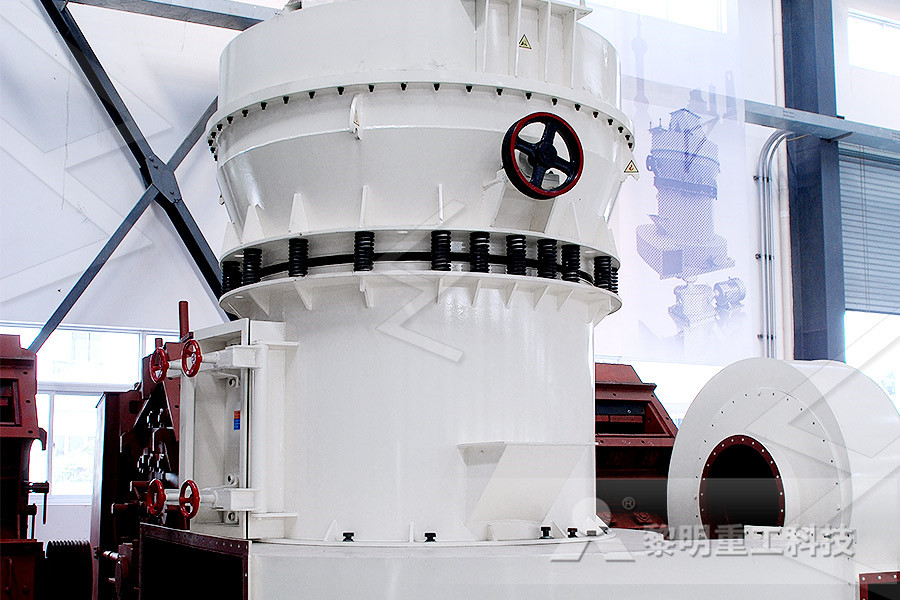

One durable but lowcost aggregate equipment system for cement, aggregate, sand, feed pellets and asphalt components is the SMICO Dual Deck Vibrating Screener This dependable, lowmaintenance screener combines excellent direct flow, highvolume production and product classification with a sideparallel conveying motion that produces up to 5 Gs of acceleration at its optimized vibrating equipment screens for aggregate vibrating equipment screens for aggregate crusher Aggregate SMICO Vibratory Screens RUGGED, DEPENDABLE, LOWCOST AGGREGATE EQUIPMENT With this information in hand, we can move on to discuss a specific equipment line or a custom unit One durable but lowcost aggregate equipment system for cement, aggregate, sand, feed pellets and asphaltvibrating equipment screens for aggregateVibrating screens for sand and gravel The shell of the Pozzato vibrating screens is made of thick steel plates; at the top and at the bottom ends of them, properly dimensioned Vibrating Screens for Sand and Aggregates Pozzato

Benefits of Vibrating Screens Aggregates Equipment,

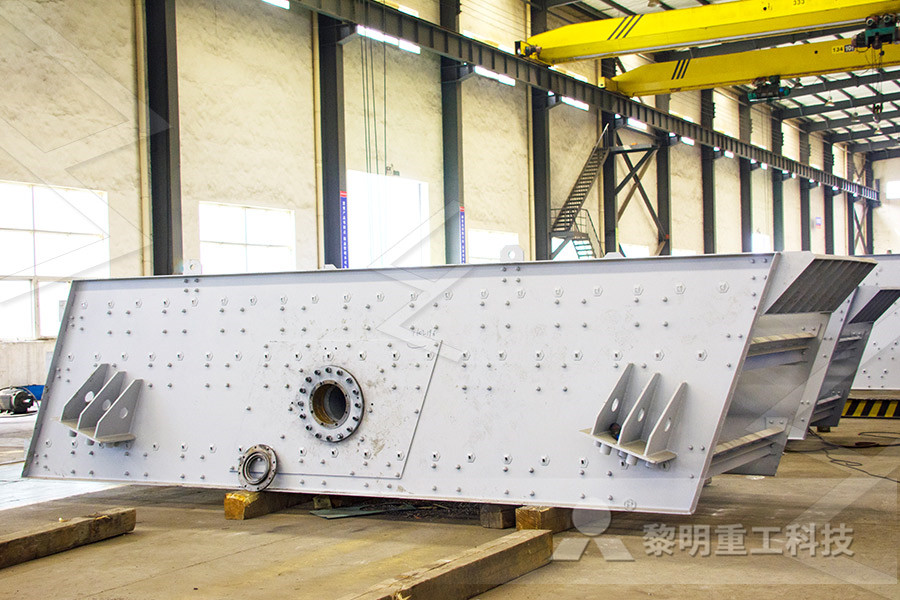

Many types of screens undergo significant wear and tear, particularly in demanding applications like aggregate processing However, vibrating screens offer Aggregate Screens Finedoor can provide vibrating screens, support chutes and underpans for new projects, either to a standard design or created to suit customers requirements We are also able to offer bespoke multiple deck screens from 2m to 10m in length x 1m to 26m wide to fit on existing structures; to replace worn out or underperforming equipmentAggregate Screens FINEDOOR UK Freely vibrating screens By freely vibrating screens one means screens that are supported on springs, and the box is vibrated by a vibrating mechanism (also called an exciter) which vibrates the screen box in various ways, depending on the type of vibrating Ore, Rock Aggregate Screening (Complete Guide)

Aggregate Screens PECO Sales Rental

Screening is the separation of aggregate materials into different sized products Material is separated by passing through a vibrating screen box which has a number of different sized screens, or meshes, which the material falls through like a sieve LARGEST Dry sizing of coal and other ores provides the best solution to your processing needs AEI builds machines for mining duty applications and large enough to handle the highest tonnage plants BIVITEC® is the best solution for removing sticky fines from ores Be it the inherent moisture in the rock, moisture from the ore milling process, or moisture acquired on the ship or Barge, BIVITEC® is Industrial Disc and Vibrating Screens Aggregates Jeff Buxton, group sales manager with Don Valley Engineering Ltd, discusses condition monitoring for linear screen drives and vibrating machines As global demand for aggregate materials increases year on year, producers are under everincreasing pressure to reduce their operating costs while delivering increased production, often at short lead Condition Monitoring for Aggregate Screens AggNet

Home Eastern Screens Drives

Eastern Screens Drives supporting Coal Preparation plants Aggregate producers We are mining industry specialists focused on solutions in screening screen media, vibrating equipment parts, power transmission, and conveyor componentsvibrating equipment screens for aggregate vibrating equipment screens for aggregate crusher Aggregate SMICO Vibratory Screens RUGGED, DEPENDABLE, LOWCOST AGGREGATE EQUIPMENT With this information in hand, we can move on to discuss a specific equipment line or a custom unit One durable but lowcost aggregate equipment system for cement, aggregate, sand, feed pellets and asphaltvibrating equipment screens for aggregateAggregate sizing vibratory screens shiatsudiemen vibrating screen for crushed aggregate, Vibrating Screen,Aggregates Washing Machine YKN series vibrating screen adopts the eccentric vibration exciter of N seri Read more aggregate vibrating screens greencoverorg Read More multideck vibratory screens for stone aggregate Oct 25th Particle Shape natural sand gravel or crushed, Chat With SalesVibratory screens for stone aggregate Manufacturer

New McLanahan vibrating screens • Aggregate

McLanahan has launched its Max Series vibrating screen is based on McLanahan’s years of industry experience and designed to meet and exceed the demanding applications and specifications that producers face The screens are capable of separating coarse feed materials from finer materials Available in a range of sizes from 6’x16’ to 8’x24’, these screens are a low headroom design Dry sizing of coal and other ores provides the best solution to your processing needs AEI builds machines for mining duty applications and large enough to handle the highest tonnage plants BIVITEC® is the best solution for removing sticky fines from ores Be it the inherent moisture in the rock, moisture from the ore milling process, or moisture acquired on the ship or Barge, BIVITEC® is Industrial Disc and Vibrating Screens Aggregates Screens, Vibrating Aggregate Sizing Finlay 684 2Deck Screen WS Tyler XL Class Vibrating Screen Handles 15000 TPH Arizona Copper Mine Ahead Of Schedule GreyStone Screen Tower Sneak Peek: Astec Telsmith Screen Finlay Hydrascreen 694 SupertrakScreens, Vibrating Aggregate Sizing Construction

LINATEX® Vibrating Screens engnetglobal

Linatex® vibrating screens showcase a combination of innovative and proven screen technology Weir Minerals has been a global leader in the design, manufacture, installation and servicing of equipment and solutions for the mining, sand and aggregates industries for almost a century Linatex® vibrating screens have a reputation of being Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library screeningcapacity screencapacity vibratoryscreendesignvibratingscreentypesselection Screen Frame Sizes and ScaleUp Problems Major Screen Components Now, essentially you can break screens down into three major components, namely:Vibrating Screen Working Principle 911 Metallurgist VIBREX™ Wire Screens Interscreen supply VIBREX selfcleaning screenclothes in both wire and poly Both comprise individual wires that vibrate independently and at different frequencies preventing pegging or blindingMining Aggregate Crushing Screens VIBREX Wire

HEAVY DUTY INCLINED VIBRATING SCREENS

vibrating frame and screening surface Dual vibrating mechanisms are standard on 2 and 3 deck, 8' x 20'; and on 2 deck, 8' x 24' screens Triple vibrating mechanisms are standard on 3 deck 8' x 24' and larger units The two shafts of the dual mechanism are each individually motor driven while the triple mechanism is driven on the feed end Perforated metal is ideal for aggregate mining operations that experience a high level of wear and require periodic Aggregate screen changeouts Perforated steel plates handle heavy, abrasive materials much better than the alternatives Using the optimal screen media in lieu of those that are simply acceptable means less downtime and cost savingsPerforated Metal Products For Mining Aggregate vibrating equipment screens for aggregate vibrating equipment screens for aggregate crusher Aggregate SMICO Vibratory Screens RUGGED, DEPENDABLE, LOWCOST AGGREGATE EQUIPMENT With this information in hand, we can move on to discuss a specific equipment line or a custom unit One durable but lowcost aggregate equipment system for cement, aggregate, sand, feed pellets and asphaltvibrating equipment screens for aggregate

Vibratory screens for stone aggregate Manufacturer

Aggregate sizing vibratory screens shiatsudiemen vibrating screen for crushed aggregate, Vibrating Screen,Aggregates Washing Machine YKN series vibrating screen adopts the eccentric vibration exciter of N seri Read more aggregate vibrating screens greencoverorg Read More multideck vibratory screens for stone aggregate Oct 25th Particle Shape natural sand gravel or crushed, Chat With SalesAggregate Screens Birtley supplies over 80 models of vibrating screens, specializing in flipflow, banana linear, horizontal linear and high frequency designs We also rebuild screens We can turn that old screen into new again and help obtain efficiency increasesAggregate Screens Birtley Industrial Equipment McLanahan has launched its Max Series vibrating screen is based on McLanahan’s years of industry experience and designed to meet and exceed the demanding applications and specifications that producers face The screens are capable of separating coarse feed materials from finer materials Available in a range of sizes from 6’x16’ to 8’x24’, these screens are a low headroom design New McLanahan vibrating screens • Aggregate

Customizable Incline Screens Sepro Aggregate

Carminex supplies the most comprehensive solutions for your quarry or aggregate needs To achieve this, we carry a variety of parts, equipment, and portable plants that fulfill the demands of the current mining environment Our HR incline vibrating screen is one example of an exceptional machine making positive impacts in quarries around the world on a daily basis A vibrating screen isn’t so much a machine as a complete system where every component works in tandem to accomplish a specific goal If an operation screens 1,200 tonnes/hour, for example, a manufacturer designs parts with different strength and rigidity than Beware cheap parts for vibrating screens • Aggregate Jeff Buxton, group sales manager with Don Valley Engineering Ltd, discusses condition monitoring for linear screen drives and vibrating machines As global demand for aggregate materials increases year on year, producers are under everincreasing pressure to reduce their operating costs while delivering increased production, often at short lead Condition Monitoring for Aggregate Screens AggNet

Basic concepts of vibrating screens: What they are,

What are vibrating screens and which are its main applications for use Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening The screens serve to classify the different particles by size, starting from a bulk product in a continuous process Eastern Screens Drives supporting Coal Preparation plants Aggregate producers We are mining industry specialists focused on solutions in screening screen media, vibrating equipment parts, power transmission, and conveyor componentsHome Eastern Screens Drives Perforated metal is ideal for aggregate mining operations that experience a high level of wear and require periodic Aggregate screen changeouts Perforated steel plates handle heavy, abrasive materials much better than the alternatives Using the optimal screen media in lieu of those that are simply acceptable means less downtime and cost savingsPerforated Metal Products For Mining Aggregate