crusher material jaw ataFinch

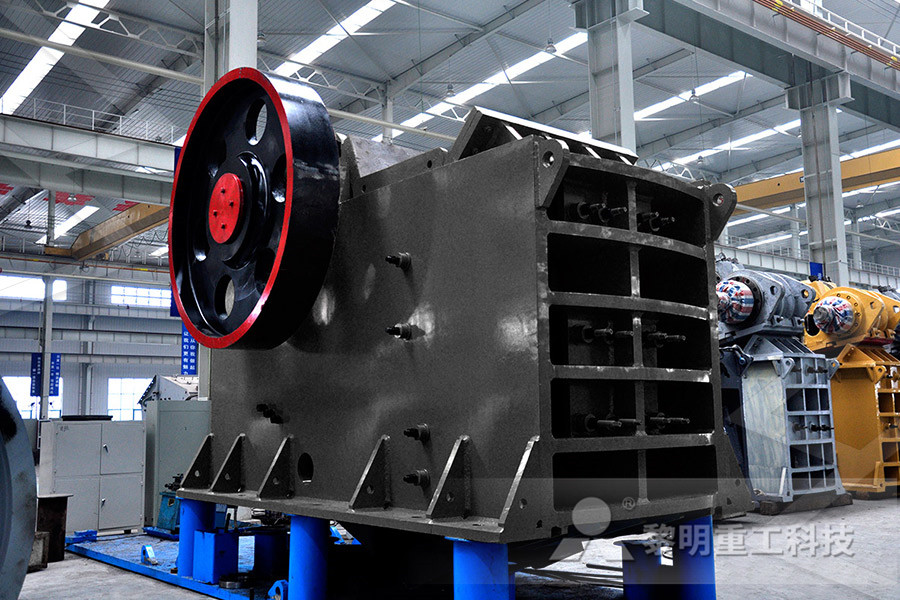

jaw crusher primarycrusherin mining aggregate jxsc Jaw crusher is a heavyduty machine that crushes hard materials So its hence muse be robustly constructed Crusher frame is made from steel or cast iron The jaws are made of cast steel Mn18Cr2 Jaw Plates Mn18Cr2 is the most popular material for casting jaw crusher jaw plates This Mn18Cr2 jaw plates widely in crushing difficult and nonabrasive blasted rock, medium and nonabrasive,nonabrasive gravel, and nonabrasive round rock Mn22Cr2 Jaw Plates Mn22Cr2 jaw plates are widely used in crushing hard and abrasive stoneWhat is the best material for crusher jaw plates? The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time This is dependent on the area of the discharge opening, the properties of the rock, moisture, crusher throw, speed, nip angle, method of feeding and the amount of size reductionJaw Crusher an overview ScienceDirect Topics

Material Selection for Crusher Jaw in a Jaw Crusher

The heavy duty machines use in the first mechanical stage of comminution are mainly jaw crushers The distinctive feature of this class of crusher is the two plates which open and shut like animal Jaws (Grieco and Grieco, 1985), this jaw is called crusher jaw The crusher jaws are set at an acute angle such that one jaw is pivoted and the other jaw is fixed The pivoted jaw swings around the pivot and make impact on the fixed jaw, crushing the fed lumps in the jaw crusher Crusher jaw, Material selection, CES EduPack, Fracture, Comminution 1 Introduction The mining and preparation of ore for extraction of the valuable minerals and production of a commercial end product of such minerals is called mineral processing or ore Material Selection for Crusher Jaw in a Jaw Crusher Manganese Crusher Jaw Plates Manganese steel’s ability to work harden from impact loading along with its exceptional toughness make it the best wear material choice for many demanding applications The hardness of manganese steel in the solution annealed and water quenched condition is normally around 220 HB It is possible to strain to harden this material to approximately 500 HBCrusher Jaw Plates Material Selection

Material For Jaw Crushers Crusher Mills, Cone

Coal Jaw CrusherJaw CrusherUsed Jaw Crusher For SaleJaw Crushing materials: Jaw crusher can crush granite, black trap, basalt, river gravel, bauxite, marble, slag, hard rock, limestone, coal, iron ore, magazine ore and so onThe crusher jaws are set at an acute angle such that one jaw is pivoted and the other jaw is fixed The pivoted jaw swings around the pivot and makes the impact on the fixed jaw, crushing the fed lumps in the jaw crusher Jaw crusher plates are the main jaw Jaw Crusher Plate Material mgscastingJaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but Jaw Crusher an overview ScienceDirect Topics

Jaw crusher,Jaw crushers,Jaw crusher supplier,stone

[Applicable Material]: Jaw crusher is a kind of stone crushing machine which is widely used as primary or secondary crusherBaichy manufactures coarse jaw crusher and fine jaw crusher in stationary type or mobile typeThe pivoted jaw swings around the pivot and make impact on the fixed jaw, crushing the fed lumps in the jaw crusherEssentially, the task of selection is that of matching the choice of material to the requirements of the design (Ashby, 2005 and Charles etal, 1997) Novel or well selected materials provide designers with excellent features(PDF) Material Selection for Crusher Jaw in a Jaw Jaw crusher plates are the main jaw crusher parts, which need to change frequently So it is the most important thing that how to decrease the cost In order to decrease the replacement cost, choose the right material for your jaw crusher is the first thing There is some material for jaw crusher plateJaw Crusher Plate Material mgscasting

What Is A Jaw Crusher Advantages, Types, Parts And

Jaw crusher Advantages Optimize the crushing cavity type to make the stroke at the bottom of the crushing cavity larger, the material handling capacity is stronger, and the crushing efficiency is greatly improved Modular design is adopted to save time and installation cost, and Crusher Jaw Plates Material Selection Different crush stone, different work conditions, need to select the right material suit to cast crusher jaw plates For example, Mn14 jaw plates can crush soft stone, but can not suit to crush hard stone, because it wears out speed too quickly if use Mn14 jaw Crusher Jaw Plates Material Selection The moving jaw moves back and forward against the fixed jaw, and material fed from the top of the machine is compressed between the two, breaking it into smaller pieces As the moving jaw moves away from the fixed jaw, the crushed material is discharged from the crusher at the bottom, with the size of the ejected material determined by the gap What is a Jaw Crusher? – MEKA Crushing Equipment

Material For Manufacture Jaw Crusher

Material For Manufacture Jaw Crusher Jaw crusher is a unique machinery applicable for all types of stones starting from the softest one and ending with the hardest one treatment of any bulk material Primary crushers ideally work reliably and with a minimum of wearandtear Jaw Cursher Sale – Crusher,Stone Crusher machine,Jaw crusher Jaw crusher is a kind of excellent mine crushing machine and can crush materials with various size to small piecesAnd the jaw ©2010 BinQ Intellectual PropertyMaterial Properties For Jaw Crusher Machine Crusher Jaw crusher A jaw crusher is a compression type of crusher Material is reduced by squeezing the feed material between a moving piece of steel and a stationary piece The discharge size is controlled by the setting or the space between those two pieces of steelRock Crusher Eastman Rock Crusher

Jaw Crusher an overview ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but Jaw crusher is commonly known as jaw breaking, also known as tiger mouth A crushing chamber is composed of two jaw plates, a movable jaw and a static jaw, which simulates the movement of the two jaws of the animal to complete the crushing operation of the materialJaw Crusher Sanme [Applicable Material]: Jaw crusher is a kind of stone crushing machine which is widely used as primary or secondary crusherBaichy manufactures coarse jaw crusher and fine jaw crusher in stationary type or mobile typeJaw crusher,Jaw crushers,Jaw crusher supplier,stone

Jaw Crusher For Sale Jaw Crusher Jaw Crusher

When feeding the jaw crusher, the material is poured from the top inlet into the crushing chamber containing the molars, which force the material to the wall of the chamber and break it into smaller stones Supporting the movement of the caries is an eccentric shaft that runs through the fuselage frameCrusher Jaw Plates Material Selection Different crush stone, different work conditions, need to select the right material suit to cast crusher jaw plates For example, Mn14 jaw plates can crush soft stone, but can not suit to crush hard stone, because it wears out speed too quickly if use Mn14 jaw Crusher Jaw Plates Material Selection The moving jaw moves back and forward against the fixed jaw, and material fed from the top of the machine is compressed between the two, breaking it into smaller pieces As the moving jaw moves away from the fixed jaw, the crushed material is discharged from the crusher at the bottom, with the size of the ejected material determined by the gap What is a Jaw Crusher? – MEKA Crushing Equipment

Jaw Crusher blocking material causes and solutions

Jaw crusher jump stop is the main reason for blocking material under the jaw crusher cavity row not too much plot material, withstand dynamic cone, resulting in motor overload jump stop Jaw Crusher Working Principle material crushing There are usually two cases resulting jump stop: The first: jaw crusher, high yield, slat conveyors too late PE/PEX Series Jaw Crushers has the features of high crushing and even product size ratio jaw crushers can be used to crush material, whose compression strength is not more than 320MpaSanme is a jaw crushers supplierJaw CrusherSANME The correct nip angle between the movable and fixed jaw dies ensures good bite and material flow down, even with slippery feed material It also reduces wear on the jaw dies, reducing operating costs With a good grip, the jaw crusher can crush rocks efficiently through the entirety of the cavity, and the nip angle can be further improved withEngineered for the toughest feed materials ® C

Jaw Crusher Premiertrak 330

Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear parts