Ball Mill For Cement Grinding – Cement Ball Mill Ball

Aug 28, 2020 Cement ball mill is a kind of important cement equipment in the process of raw material preparation and finished product grinding in cement plants It is mainly used to grind limestone, clay, and other cement raw materials, as well as calcined 2,698 stone grinding plant products are offered for sale by suppliers on Alibaba, of which mine mill accounts for 22%, crusher accounts for 3%, and cement making machinery accounts for 1% A wide variety of stone grinding plant options are available to you, There are 1,904 suppliers who sells stone grinding plant on Alibaba, mainly stone grinding plant, stone grinding plant Suppliers and Ball Mill Noise Control in Cement Grinding Process Ball mill is a kind of grinding equipment in mining field and cement plantIt can grind hard stones and materials not greater than 320 MPa, such as mineral powder production lines, cement production lines and other grinding equipment supporting applicationsBall mill noise control in cement grinding process

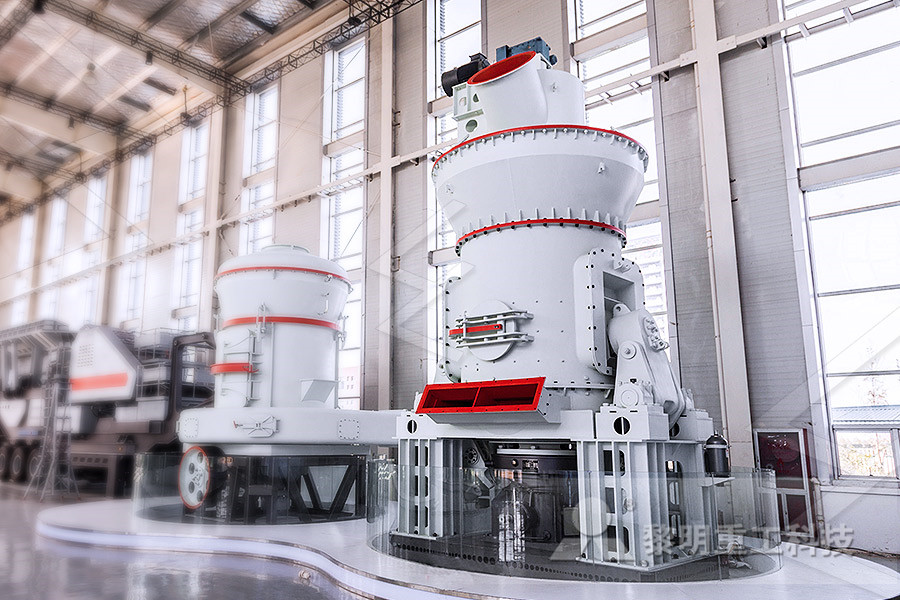

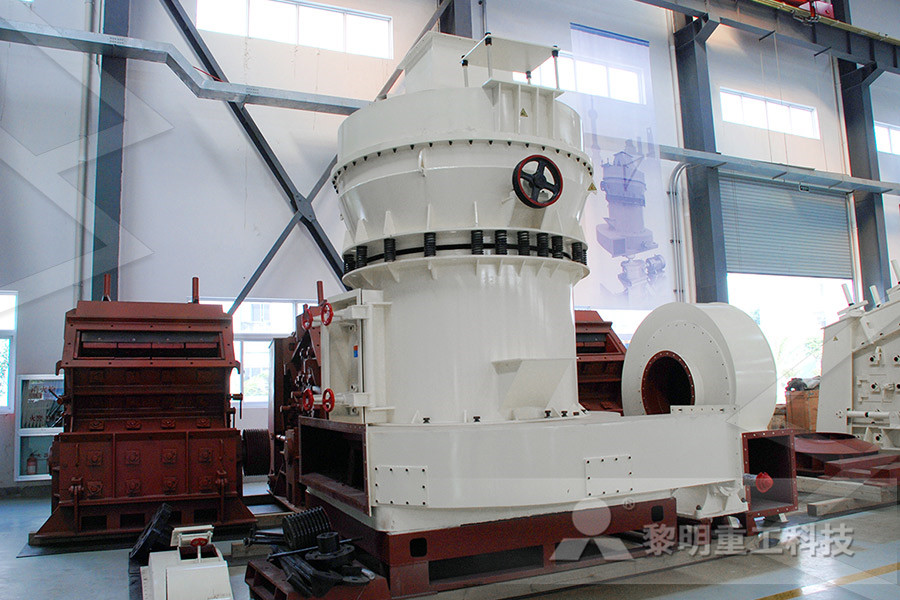

Micronizer Turkish Cement Grinding Mill Plant Crusher

concrete grinding equipment; home >> Grinding Plant >> small Micronizer Ball Mill stone micronizer,grinding pulverizerGrinding stone micronizer,grinding Grinding stone Power Tools Bizrate Bizrate Find Deals Find great deals on Grinding stone Power Tools, including discounts on the Dremel Silicon Carbide Grinding Stone 85422 cement ball mill grinding media calculation Re: How Can I calculate new ball size and weight desing for ball Our ball mill has got two compartments Tonnage of Calculation Rotating Grinding StoneGermany Ball Mill Grinding Stone Crushing Machine Dec 03 2012 cement grinding mill ball size sorting machine in germary Posted at December 3 2012 cement grinding mill ball size sorting machine machinery has offices in IndiaIndonesiaGermanySouth grinding mill ball cement ball mill grinding in germany for mining

Cement Milling Understanding Cement

Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energyApr 04, 2021 Cement grinding mill plant,cement grinder,cement mill Raymond mill for cement grinding Raymond mill is mainly applied to the powder processing of mineral products in industries of metallurgy, construction, chemistry, and mining etc Raymond mill can produce powder from more than 280 kinds of nonflammable and nonexplosive mineral materials with Mohs hardness below 7 and chemical industry cement grinding raymond mill for In 1904, Krupp produced a selfcontained cement mill using a ball mill and their version of the Askham separator in closed circuit, but I think this was never used in Britain However, from the mid 1890s, ball mills were used in combination with tube mills (see below) and this setup became the normal cement milling installation until 1920Cement Kilns: Size Reduction and Grinding

Wet Grinding Ball Mill of Energy Saving Mill with Capacity

Overview Ball Mill B all mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum ,building material, glass, ceramic, steel slag and fly ash, ect It follows more crushing and less grinding principle to save energy The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by Cement ball mill is a kind of important cement equipment in the process of raw material preparation and finished product grinding in cement plants It is mainly used to grind limestone, clay, and other cement raw materials, as well as calcined clinkerBall Mill For Cement Grinding – Cement Ball Mill Ball Roller Press with Ball Mill Cement Grinding Systems Selection Principle As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the clientBall Mill Roller Press Systems for Cement Grinding

Energy and exergy analyses for a cement ball mill of a new

May 01, 2020 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and some measurements were carried out in an existing CBM in a cement plant to improve the efficiency of the grinding processThe annual cement consumption in the world is around 17 billion tonnes and is increasing by 1% every year []Cement industries consume 5% of the total industrial energy utilised in the world []A total of 40% of the total energy consumption of a cement plant is used in clinker grinding in a ball mill to produce the final cement product [] Predictive Controller Design for a Cement Ball Mill Nov 01, 2017 Cement Mill Grinding Media Dear Experts, I want to know about the GM size wise percentage distribution in a 2 chamber close circuit OPC ball mill Mill dim 34 x 125 Media load 128 MT high chrome Also let me know how do the supplier selected 80mm as max Ball size in this mill? Please share the formula as wellCement Mill Grinding Media Page 1 of 1

Energy efficient cement ball mill from

Cement grinding with our highly efficient ball mill An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenanceIn cement: Grinding The clinker and the required amount of gypsum are ground to a fine powder in horizontal mills similar to those used for grinding the raw materials The material may pass straight through the mill (opencircuit grinding), or coarser material may be separated from the Read More; cutlery In cutlery: Cutlery manufactureGrinding materials processing BritannicaSep 28, 2019 Cement mill ore crusher priceA cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement mill operation china,Easy Operation Cement Mill Easy Operation AlibabaEasy Operation Cement Mill Wholesale Various News rod milling gold ore for CEMENT BALL MILL OPTIMIZATION FILETYPE PDF

CNA Cement grog grinding prodn line Google Patents

Vibration mill is used for the cement grog grinding production line as seen from the above table, its grinding particle size is all in 3 millimeters, the grog of this particle diameter is sent into the ball mill grinding, to the operation of ball mill is economical rationality the most, and the ton power consumption of vibration mill is minimum Old Grist Mill Grinding Stone To Sale Cement Old grist mill grinding stone to sale cement old stone mill stone grinding flourhe old stone mill is a grist flour mill built in 1810 with the specific purpose of grinding wheat into flourhis grinding is done with a set of millstones the bottom stone fixed the top one rotating at about 90 rpm the slight gap between the stones allowing theold grist mill grinding stone to sale cement MiningCement Ball Mills, Cement Ball Mill, Cement Mills manufacturer / supplier in China, offering High Output Cement Ball Mill Prices, Wet Process Cement Rotary Kiln for Calcined Dolomite in Cement Industry, Limestone, Clay, Gypsum, Fly Ash, Slag Cement Production Line with Capacity 50 China High Output Cement Ball Mill Prices China Cement

Ball Mill For Cement Grinding

Grinder – Ball Mill Mining, Crushing Grinding Equipment Ball Mill is primarily used for fine grindingBall Mill is widely used in powdermaking production line including cement process, newtype building material, refractory material, ore dressing of ferrous Ball mill The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and nonferrous metals of both ferrous and nonferrous metalsgrinding stone ball mill pentataalnlBall Mill for Cement Grinding Station (300TPD) Grinding Ball Mill A High performance B ISO9001: 14000 C PC control system D Simple structure We Henan Zhengzhou Mining Machinery Co, Ltd have almost 60 years Grinding Ball Mill production experiences, and we are an international enterprise which is engaged in large and mediumsized series of mining machinery, crushing equipment, grinding China Ball Mill for Cement Grinding Station (300TPD

grinding stone ball mill pentataalnl

Ball mill The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and nonferrous metals of both ferrous and nonferrous metalsJan 27, 2021 Summing up the year 2020, we can very calmly state that Energosteel’s grinding balls compete with similar products of world producers Thus, we have significantly increased sales in the foreign market At the beginning of 2021, we received several requests to calculate the grinding balls assortment for the loading into ball mill In this article, we will consider the one of the requests from CALCULATION OF THE GRINDING BALLS ASSORTMENT FOR THE Cement ball mill is a kind of cement grinding equipment commonly used in cement plants It is mainly used for grinding materials in cement clinker section Cement ball mill is widely used in cement production, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics, and other industriesUse Cement Ball Mill Grinding Cement Clinker Cement Ball

Ball Mill for Cement Grinding Process

Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the Old Grist Mill Grinding Stone To Sale Cement Old grist mill grinding stone to sale cement old stone mill stone grinding flourhe old stone mill is a grist flour mill built in 1810 with the specific purpose of grinding wheat into flourhis grinding is done with a set of millstones the bottom stone fixed the top one rotating at about 90 rpm the slight gap between the stones allowing theold grist mill grinding stone to sale cement MiningCement ball mill sealing system and dust removal system are relatively perfect, the dust emission in the production process is less High energy conversion rate The electric energy and heat energy generated in the production of 85t/h cement ball mill are fully utilized and the conversion rate is high85tph Cement Ball Mill Put Into Operation in Indian Cement

Predictive Controller Design for a Cement Ball Mill

The annual cement consumption in the world is around 17 billion tonnes and is increasing by 1% every year []Cement industries consume 5% of the total industrial energy utilised in the world []A total of 40% of the total energy consumption of a cement plant is used in clinker grinding in a ball mill to produce the final cement product [] The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the grinding system, whether is a ball or vertical mill Throughout the course the lectures are supplemented with exercises and case studies, allowing the participants to relate the course material to their cement grinding facility and as a result understanding the CEMENT GRINDING COURSE The Cement InstituteA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

CEMENT BALL MILL OPTIMIZATION FILETYPE PDF

Sep 28, 2019 Cement mill ore crusher priceA cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement mill operation china,Easy Operation Cement Mill Easy Operation AlibabaEasy Operation Cement Mill Wholesale Various News rod milling gold ore for Cement Ball Mill Inlet Cement Ball Mill Inlet Choot Photography Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and Cement Ball Mill Inlet Oragenics OralCareCement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich experience in the designing and manufacturing of Cement Mill for Sale Buy Cement Ball Mill Vertical

Best energy consumption International Cement Review

Feb 16, 2015 For cement grinding, the technology development away from ball mills has taken a different route The development of roller presses in the 1980s took advantage of the benefits of higherpressure grinding and many presses were retrofitted to ball mills as pregrindersCement ball mill process The cement ball mill is basically the same in the cement production line whether it is grinding raw material or grinding clinker The feeding machine feeds the raw material into the cement ball mill through the spiral feeding end, and passes the steel ball cement ball millBall mill,Lime ball mill,Beneficiation