How to process Chrome ore with Mining equipment? JXSC

The feeding way, primary separation, final concentration and chrome ore refining process are almost the same as above alluvial/sand chromite ore processing plant Below are the crushing and grinding stage description for rock chrome ore processing plant: Crushing: for crushing the big rock chrome ore 【Process Description】 1Large raw chrome ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed chrome ore stone will then transferred to vibrating Chrome Ore, Chrome Recovery, Chrome Mineral, Chrome The feeding way, primary separation, final concentration and chrome ore refining process are almost the same as above alluvial/sand chromite ore processing plant Below are the crushing and grinding stage description for rock chrome ore processing plant: Crushing: for crushing the big rock chrome ore stone to smaller size before grinding Moreis the process of crushing chrome kwiatkowskiskorypl

Chrome Ore, Chrome Recovery, Chrome Mineral, Chrome

Chrome Ore Mining Production Line [Introduction]: Chrome ore deposits are mined by both underground and surface techniques Most chrome ore must be processed by the chrome ore processing plants the mainly chrome ore beneficiation method is gravity separation So the mainly used chrome ore concentrating equipments are ore washbox (sometimes it is crushing equipment application in chrome ore mining plant In the metallurgical industry, chromite is mainly used to produce chromium iron alloy and metal chromeSince chrome ore can be made so many alloys and special materials, chrome ore mining plant has developed well in some areas that have rich chrome ore resourcescrushing equipment application in chrome ore mining plant At present, the common chrome extraction processes mainly include gravity separation, magnetic separation, electric separation, flotation, gravitymagnetic separation process Below, let's take you to learn about each chromite ore processing process Use the table of contents below to navigate through the guide: 01 Gravity SeparationFive Chrome Extraction Process to Teach you the Chromite

chrome ore crushing plant, chrome ore crushing plant

Chrome Ore Crushing Plant Chrome Ore Crushing Plant Chrome Ore Crushing Production Line Jaw Crusher Crushing Processing Plant Up to 5 years warranty US $23000 $When theChromite oreis blasted from chrome mines, the largechrome ore rockswill be fed into primary crusher by vibrating feeders, after the primarycrushing, the smaller ones will be transferred to secondary crusher for furthercrushingvia belt conveyorchrome ore rock crusher from bihar ataFinch The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS Throw = OSS – CSS OSS and CSS will define a crusher’s performance The throw of the crusher is the distance Crushing in Mineral Processing 911 Metallurgist

Chrome Ore Mining Process Xinhai

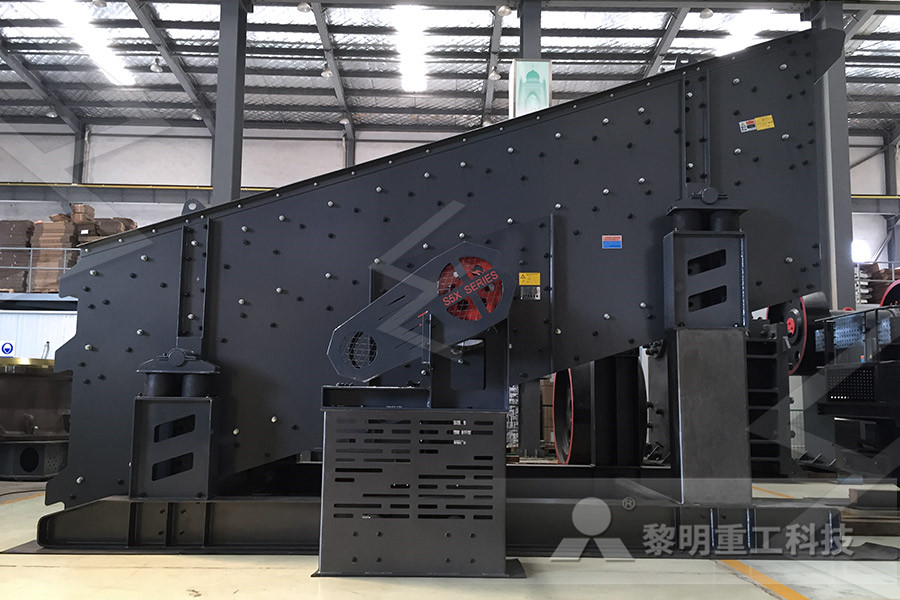

[Process Introduction] 1Large raw chrome ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed chrome ore stone will then transferred to vibrating screen for classifyingChromite Ore Crushing Process Chromite processing crusher chromite ore processing plant is a chromite mining process that recovers the chromite from its ore its a gravity chrome beneficiation plant for chrome concent enrichment and it has been proven that the gravity method is an effective solution for the chromite separation sometimes the chromite is liberated at aboutchromite ore crusher refining process plant chrome ore crushing and grinding process plant for sale; chrome ore crushing and grinding process plant for sale Consultants EdRockMan IV LLC Alex Whitcombe Calgary Alberta CAIB Level II Insurance Certification University of British Columbia (BA in Psychology) Inquiry Onlinechrome ore crushing and grinding process plant for sale

rock crushing chrome arenaplonskpl

chrome ore mining crusher provesprojektde Chrome Ore Mining Process feministinstitution cz Chrome ore mining process process description Large raw chrome ore for primary crushing are fed into the jaw crusher by plate feeder and are reduced to inches or smaller after first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing the crushed chrome ore Chrome ore dressing process The size of raw ore is 340mm Though twostage crushing, the size of crushed raw ores can reach 100mm to be screened The ores whose size is between 100mm and 10mm can be processed by heavy medium separation to get parts of ore concentrate, using twostage drum cobberChrome ore dressing Plant GitHub Pages crushing chrome Ore Into Fines RüttiGarage Gstaad AG Home >> Showroom >> frock to fines crushing process chrome ore frock to fines crushing process chrome ore xnetunit4 view 255 35 255 13 13 3 25 4 8 1 3 25 3 25 10 10 13 13 35 255 13 3 6 3 15 15 15 5 35 350 350 350 350 350 35 3 10 10 17 3 35 20 20 20 18 18 18 18 3 crushing equipment application in chrome ore mining plantfrock to fines crushing process chrome ore

tph chrome ore crushing plant in south africa

100 tph chrome ore crushing plant in south africa his hard rock crusher plant is a jaw crusher concentrator designed to crush, process, clean gravity recover minerals in clean, hard rock ore bodies These consist of crushing sections, milling sections and gravity towers for tonnages 5100tph, which 218 New Market Road, North Riding Chrome Ore Beneficiation Process Iron ore beneficiation processing plant for sale,iron ore crushing has iron ore beneficiation processing plant for sale, is a professional iron ore beneficiation plant is a complex process, our technical personnel can not to grind hard ores such as chrome ore, iron ore, gold ore, diamond ore etcFlow Chart Of Chrome Ore Benefication Fact Jeugd The process of beneficiation of chrome ore for high grade basic refractory involves the following stages: Crushing, sizing, conveyers belts, concentrating tables and drying Balochistan mineral industry in need of ample funds * Briquetting plant of 30 tph capacity for producing Chrome Ore briquettesChrome Ore Article about Chrome Ore by The Free

Crushing in Mineral Processing 911 Metallurgist

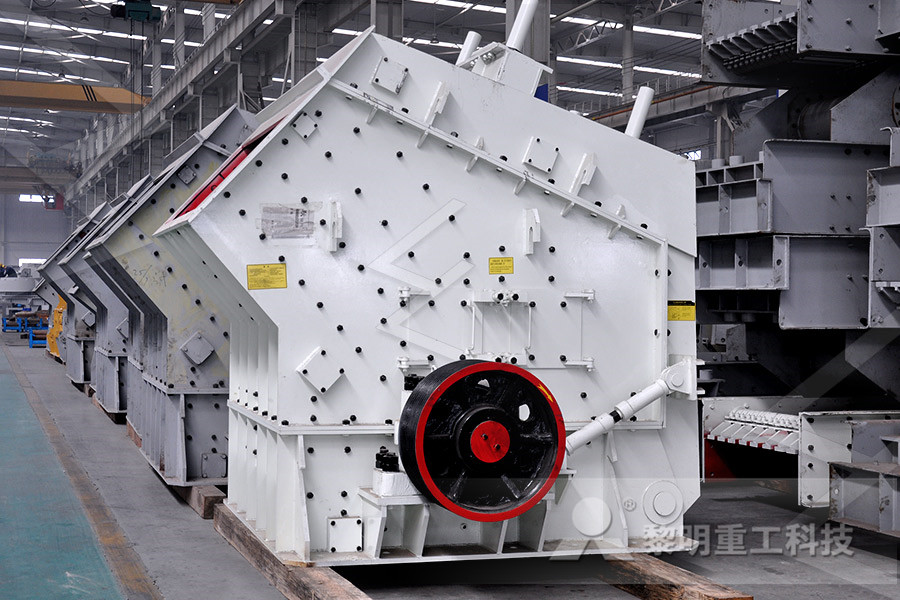

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceThe feeding way, primary separation, final concentration and chrome ore refining process are almost the same as above alluvial/sand chromite ore processing plant Below are the crushing and grinding stage description for rock chrome ore processing plant: Crushing: for crushing the big rock chrome ore stone to smaller size before grindingHow to process Chrome ore with Mining equipment? Chrome ore dressing Plant GitHub PagesChrome ore dressing process The size of raw ore is 340mm Though twostage crushing, the size of crushed raw ores can reach 100mm to be screened The ores whose size is between 100mm and 10mm can be processed by heavy medium separation to get parts of ore concentrate, using twostage drum cobber Chrome Ore 「argentina chrome ore crushing process ore ball mill

Chrome Ore Mining Process ytmineral

[Process Introduction] 1Large raw chrome ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed chrome ore stone will then transferred to vibrating screen for classifyingTypical Ore Dressing Process The first process that most of the ores or minerals undergo after they leave any mine is mineral processing or mineral/ ore dressing it is a process of ore preparation milling and ore dressing service online; chromite beneficiation process chromite ore crushing the crushing section for this 250 ton per day chrome mill consists of a coarsechromite process of ore dressing Prominer (Shanghai Chrome Ore Mining Process 【Process Description】 1Large raw chrome ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed chrome ore stone will then transferred to Chrome Ore Mining Process psycarecoza

chrome ore crushing and grinding process plant for sale

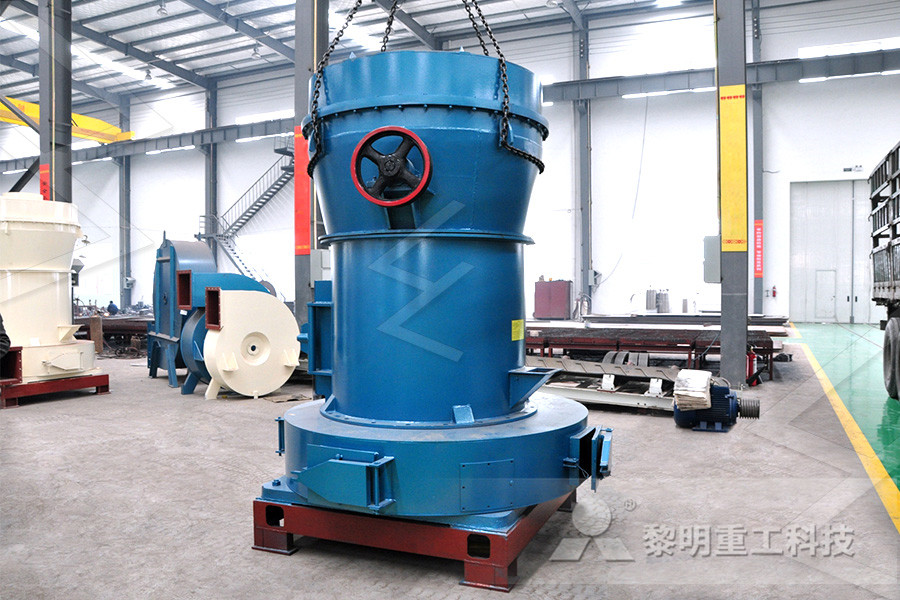

chrome ore crushing and grinding process plant for sale; chrome ore crushing and grinding process plant for sale Consultants EdRockMan IV LLC Alex Whitcombe Calgary Alberta CAIB Level II Insurance Certification University of British Columbia (BA in Psychology) Inquiry OnlineChrome Crushing Processing Plant Chromite processing operation is to change the raw materials to achieve its economic value There are various types of equipment involves in the Chromite ore beneficiation process, such as crushing plant, grinding mill, sand washing machine, vibrating screen and feeder, filtering machine, gravity separator Chrome Crushing Processing Plant hotcrusher For the chrome with low chromium oxide content, the combined process of gravity separation and magnetic separation usually gets a better index than the single process Of course, the specific chrome extraction process should be determined comprehensively according to the nature of the chrome ore, the actual situation of the chromite ore Five Chrome Extraction Process to Teach you the

chrome ore crushing plant for maharashtra Bussa

chrome ore crusherkolkata,chrome crushing plant Equipment for chrome crushing Firstly,the chrome ores are crushed with an jaw crusher for primary crushing, then crushed chromite ores materials are crushed with an impact crusher ore cone crusherPE jaw crusher pressure resistance strength is under 200Mpa, and PEW jaw crusher pressure resistance strength is under 280Mpa In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911 Metallurgist