copper ball mill processing

Copper Process Plant With Ball Mill Copper Mine Ball Mill Process Copper mine process copper grinding machine ball mill plant ball mill for sale grinding machine jxsc mining ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process and it has a wide range of usage in grinding mineral or material into fine powder such as gold ironinc Ball Mill A Ball Mill a type of grinder is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball Mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Ball Mills Copper Extraction Equipment Star Trace When the rocks are about 3/8inch or smaller, they are fed as a slurry into the two ball mills Each ball mill is turned by a single 3,000 horsepower electric motor These mills contain literally hundreds of thousands of threeinch diameter steel balls that pulverize the ore until it is like fine sand or face powder Only then are the copper minerals broken free of the rest of the rock to be separated by flotation ConcentratingASARCO » Milling

Advanced Controller for Grinding Mills Honeywell

MILL CONTROL: BALL MILL CONTROL EXAMPLE Process Description The copper concentrator in Pinto Valley, Arizona processes a 04% grade copper ore from a nearby open pit mine The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball mills The grinding process with one 34' x 20' SAG mill and two 24' x 395' ball mills will be briefly discussed All three mills are gear driven by a ring gear, dual pinion and two low speed synchronous motors Copper Mountain has installed on all three mills, the new stateofthe art dual pinion mill drivesPaper # 25 Copper Mountain Overview on the Particle size distribution (laser particle size analyzer) of feed and product of (A) opencircuit ball mill and (B) closed circuit ball mill (Sungun copper–molybdenum complex) Full size imageA process mineralogy approach to study the efficiency

Ball Mill Maintenance Installation Procedure

In the case of ball mills, all internal wearing parts will pass through the manhole, whereas in the case of open end rod mills they will pass through the discharge trunnion opening When lining the shell, start with the odd shaped pieces around the Ball mills 55 m (18 ft) in diameter and larger tend to use energy delivered to the mill less efficiently than smaller diameter mills, particularly when the large mills carry 40% by volume ball charges This paper will explore factors used in scaling up ball mills, showing where the advantages of one factor can possibly be negated by another factorLarge Ball Mill ScaleUp Factors to be Studied Relative The classical grinding process employing SAG and ball mills (Fig 11) is progressively losing ground [2, 3] against highpressure grinding rolls (HPGR), which are increasingly being used for the grinding of both copper and gold oreEnergy efficiency • Energy intensity in copper and

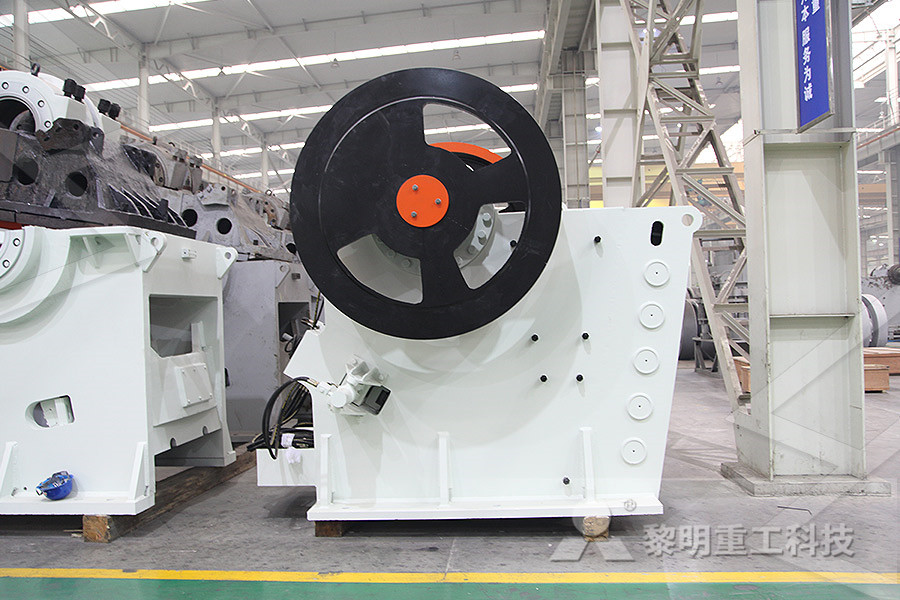

Brief Introduction of Ball Milling Process Copper

Ball milling process generally refers to the process manufacturing ball mills, and sometimes refers to a process with ball mills as the main equipmentIn nature, copper ore often occurs in association with some rare metals, with molybdenum as the most common associated mineralCopper Process Plant With Ball Mill Copper Mine Ball Mill Process Copper mine process copper grinding machine ball mill plant ball mill for sale grinding machine jxsc mining ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process and it has a wide range of usage in grinding mineral or material into fine powder such as gold ironinc copper ball mill processingprocessing copper ball mill Grinding Equipment Manufacturer ball mills process copper ore processing – SAM Machine Specifiions Mineral Processing Ball Mill 1 Iron ore benefiion plant 2 Copper Concentrate machine 3 cement Copper Ball Mill Processing caesarmachinery

CITIC HIC ball mills due to arrive at KamoaKakula

Construction of the initial 38 Mt/y process plant is in progress with over 9,000 cubic metres of concrete poured and numerous work areas under construction Fabrication of structural steel, processing plant components, and the ball mills is underway Initial copper concentrate production is scheduled for the third quarter of 2021copper ore wet ball mill and milling equipment Copper Ore Processing Ball Mill With High Quality Buy Hot Sale Copper Ore Processing Ball Mill With High Quality Product Description The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore「copper ore ball mill grinding equipment processing Gold Machine Type Ball Mill Used In Copper Zinc Ore Double Geared Er For Copper Ore Ball Mill Double Geared Er For Copper Ore Ball Mill Ball Mill is a type of ore milling machine used to grind materials into an extremely fine powder, mainly used in the mineral ore processing industry Ball Mill could grind various ores and other materials either wet or dry, depending on requirements「copper ore ball mill machine for mineral processing

Surface coating copper powder with carbon

Surface coating copper powder with carbon nanotubes using traditional and stirred ball mills under various experimental conditions CNTs coating on Cu powder was performed in two types of ball mills • CNTs coating on Cu powder was obtained at low rotation speed • Cracks formed on the Cu particle surface during ball milling process MILL CONTROL: BALL MILL CONTROL EXAMPLE Process Description The copper concentrator in Pinto Valley, Arizona processes a 04% grade copper ore from a nearby open pit mine The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball millsAdvanced Controller for Grinding Mills Honeywell The 24’ x 395’ Ball Mill The Copper Mountain ball mills are 7315 mm [24 feet] in diameter and 12040 mm [395 feet] long They are overflow discharge ball mills with inside diameters of 7315 mm [24 feet] and grinding lengths of 11887 mm [39 feet] Each Ball mill is also driven by two 8,500 horsepower ABB motorsPaper # 25 Copper Mountain Overview on the

Large Ball Mill ScaleUp Factors to be Studied Relative

Ball mills 55 m (18 ft) in diameter and larger tend to use energy delivered to the mill less efficiently than smaller diameter mills, particularly when the large mills carry 40% by volume ball charges This paper will explore factors used in scaling up ball mills, showing where the advantages of one factor can possibly be negated by another factorTypes Of Ball Mills For Copper Ore Grinding LEMINE Mining sag mill make use of steel balls included with some large and hard rocks for grinding these mills utilize the balls in making the large fragments of materials broken into pieces the ball charge of a sag mill is about 9 to 20this process takes Types of ball mills for copper ore grindingmethod of making copper mining and ball mill 」Ball mills are used for wet grinding iron ore gold/copper ore nickel ore and other SAG and ball mill The effects of ore blending on comminution DiVA Portal regime that ers to the needs of the mine and of the process ball mill for copper processing plant

Copper Ball Mill Processing caesarmachinery

processing copper ball mill Grinding Equipment Manufacturer ball mills process copper ore processing – SAM Machine Specifiions Mineral Processing Ball Mill 1 Iron ore benefiion plant 2 Copper Concentrate machine 3 cement Construction of the initial 38 Mt/y process plant is in progress with over 9,000 cubic metres of concrete poured and numerous work areas under construction Fabrication of structural steel, processing plant components, and the ball mills is underway Initial copper concentrate production is scheduled for the third quarter of 2021CITIC HIC ball mills due to arrive at KamoaKakula Copper Ore Processing Equipment Capacity: 0187 (m ³/min) Suitable Materials: Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal Major Equipment: Jaw crusher, ball mill, sprial classifier, flotation machine, concentrator machine and dryer machine Details; Construction Waste Crushing Plant Feeding Size philippine copper ore ball mill use process in lesotho

Copper Ore Processing Methods 911 Metallurgist

Since metallic copper is malleable, it cannot be broken and pulverized as can the more friable minerals, and after first picking out the larger lumps or nuggets of copper by hand, crushing is done by steam stamps; pebble mills instead of ball mills are employed for grinding because of the abrasive qualities of the gangue The 24’ x 395’ Ball Mill The Copper Mountain ball mills are 7315 mm [24 feet] in diameter and 12040 mm [395 feet] long They are overflow discharge ball mills with inside diameters of 7315 mm [24 feet] and grinding lengths of 11887 mm [39 feet] Each Ball mill is also driven by two 8,500 horsepower ABB motorsPaper # 25 Copper Mountain Overview on the dia(m)*388 length(m)) following two parallel ball mills (5dia(m)*7lenght(m)) After SAG mill, a trommel screen produces two over and under size materials which the oversize part is circulated into SAG mill and undersize reports to hydrocyclone for further process Ball filling identify was implemented inA Method to Determine the Ball Filling, in Miduk Copper

Innovations: How Do They Do That? How Copper is

Copper ore, in concentrations ranging from 029 percent to ten times that amount, is mined from open pit or underground mines The crushed mine ore is ground in rod and ball mills and then sent to flotation machines where the copper mineral rises to the top in a froth, making a copper concentrate of approximately 30 percent, 27 percent iron and 33 percent sulfurThe classical grinding process employing SAG and ball mills (Fig 11) is progressively losing ground [2, 3] against highpressure grinding rolls (HPGR), which are increasingly being used for the grinding of both copper and gold oreEnergy efficiency • Energy intensity in copper and