cement vertical roller mill, cement vertical roller mill

cement vertical roller mill,cement vertical roller mill manufacturer with ISO cement vertical roller mill is an advanced grinding machine, which is developed on the basis of home amp; abroad high technology and production experience combination of various mills Separator controls the output size of finished product, greater than the specified Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materials Vertical Cement Mill Great Wall A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true competitor and alternative for ball mill and has increased its market share in the cement mills in recent timesReview on vertical roller mill in cement industry its

Vertical Roller Mill in Cement End Milling Application

Vertical roller mill application in the milling aspect well after cement has not reached the mill, which is developing rapidly and widely applied, but has evolved to the stage of practical application By vertical roller mill as final cement grinding not only have higher demands finesse, also must have a certain particle size gradation The fineness of the cement can be adjusted by adjusting the g Thailand: Siam Cement has ordered a LM 563+3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone The cement producer previously ordered a LM 563+3 CS mill from Loesche for its Ta Luang cement plant in 2014vertical roller mill Cement industry news from Global Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use VRMs for cement grinding However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classification and regrinding Vertical roller mill optimisation CemNet

Cement grinding Vertical roller mills versus ball mills

cement in a vertical roller mill, the layout, as shown in Figure 7, is prepared with provisions for recirculation of hot mill exit gas to the mill inlet to maintain a proper , cement grinding 2 % Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc There are several aspects to the normal operation of the vertical mill: The material layer of Vertical mill The proper thickness of the layer and stable layer are basis for stable operationimportant operation tips for cement vertical mill 2, cement vertical roller mill compared with roller press and remarkable power saving, per ton of cement roller press process is saving 35, the whole system power consumption than grinding system with roller press saving 15kWh/tAnalysis of vertical mill and roller press cement contrast

Vertical Cement Mill Cement Clinker Grinding

Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement mill 2 Reducing the power consumption of cement clinker preparation effectively According to the display of pulverized coal measured data, it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, Cement Vertical Roller Mill greatwallcorporation HRM Vertical Roller Mill in Cement Industry As we all know that the HRM vertical roller mill is one of very important powder making machines in the cement industry Because of the high efficient and high capacity the vertical roller mill, so use the vertical roller mill to process the cement raw powder is the most suitable machine in cement industryHRM Vertical Roller Mill in Cement IndustryHefei

Vertical roller mill for raw Application p rocess materials

vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purpose Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use VRMs for cement grinding However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classification and regrinding Vertical roller mill optimisation CemNet cement in a vertical roller mill, the layout, as shown in Figure 7, is prepared with provisions for recirculation of hot mill exit gas to the mill inlet to maintain a proper , cement grinding 2 %Cement grinding Vertical roller mills versus ball mills

Cement mills and raw mills for high throughput rates

No matter what type of material has to be ground – cement raw material, cement clinker or granulated blastfurnace slag – and how different their grindability and abrasiveness may be, the MVR mill ensures throughput rates of a different dimension, around the clock, reliably and on Coal mill is also called coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mill and vertical roller mill At present, most cement plants use coal as the main fuel in the clinker production processCoal Mill in Cement Plant Vertical Roller Mill Air SINOMALY provides various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily processed by a final Cement Mill Vertical Mill Manufacturer SINOMALY

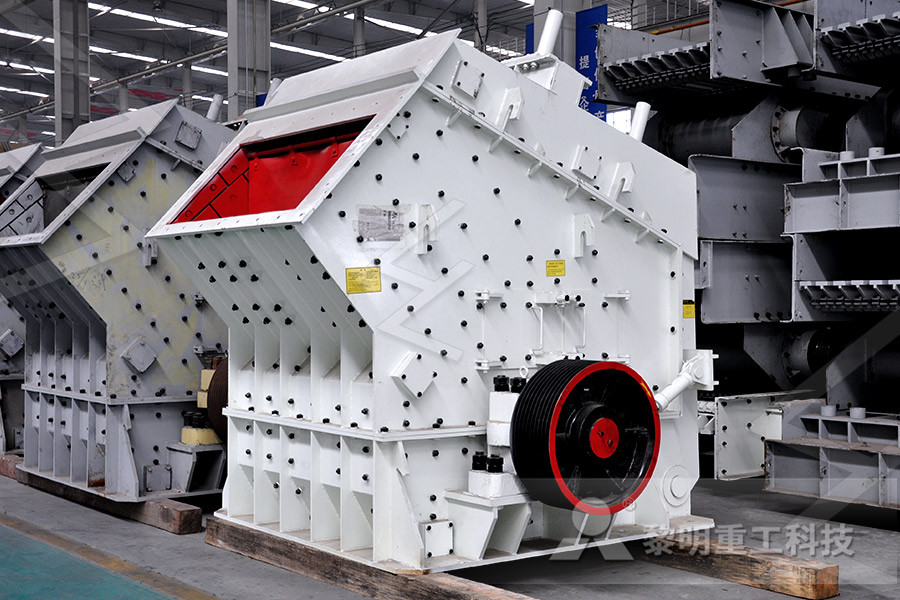

Roller Mill Components – Cement Americas

Roller Mill Components; Roller Mill Components 9 years ago Cement Americas News Roller mills, bowl mills, or vertical roller mills offer size reduction of bulk materials in coalfired power plants and cement works In coalfired power plants roller mills are used to grind coal, while in cement works they grind coal, raw meal and more recently Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement millVertical Cement Mill Cement Clinker Grinding Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc Application : Cement Plant, ClCement Vertical Roller Mill gwmcn

China Cement Vertical Mill Vertical Roller MillSlag

Therefore, cement vertical roller mill meets the national environmental protection requirements With working mechanism changing, cement vertical roller mill can be reduced friction and improved service life Specifications Model Grinding diameter d(mm) Roll diameter d(mm) Roller number (n) Standard power P(kw) capacity Q(t/h) LKCM3031 3,000Alibaba offers 2,828 vertical cement mill products A wide variety of vertical cement mill options are available to you, such as warranty of core components, local service location, and applicable industriesvertical cement mill, vertical cement mill Suppliers and 300tpd 8000tpd Roller Press Cement Mill , Large Vertical Roller Mill Contact Now 05mm Tolerance Cement Rotary Kiln , Rotary Lime Kiln For Sintering Cement ClinkerRoller Press Cement Mill factory Vertical Cement Mill

Vertical roller mill, Cement Production Line,Cement

Vertical roller mill is grinding equipment that integrates drying, grinding and powder selection The grinding roll is driven by the rotation of the grinding disc, and the material is ground into powder between the grinding roll and grinding disc After the milled material is selected, most of the coarse powder will automatically fall onto the grinding disc during the flow of the airflow Vertical roller mill for Cementos Tequendama The Tequendama cement plant near Suesca/Colombia Gebr Pfeiffer, Inc, a subsidiary of Gebr Pfeiffer SE, with headquarters in Kaiserslautern, Germany, was recently awarded a contract to supply an MPS 140 BK coal mill at Cementos Tequendama SA With this mill, the cement producer YTL will Vertical roller mill for Cementos Tequendama Coal mill is also called coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mill and vertical roller mill At present, most cement plants use coal as the main fuel in the clinker production processCoal Mill in Cement Plant Vertical Roller Mill Air

Ball Mills Or Vertical Roller Mills: Which Is Better For

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated ROLLER MILL Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet Vrm Presentation Mill (Grinding) Cement